Automatic material receiving device of oil press

A technology of material receiving device and hydraulic press, applied in the direction of stripping device, feeding device, storage device, etc., can solve the problems of easy safety accidents, low degree of automation, hidden safety hazards, etc., to ensure safe production operations, improve labor efficiency, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

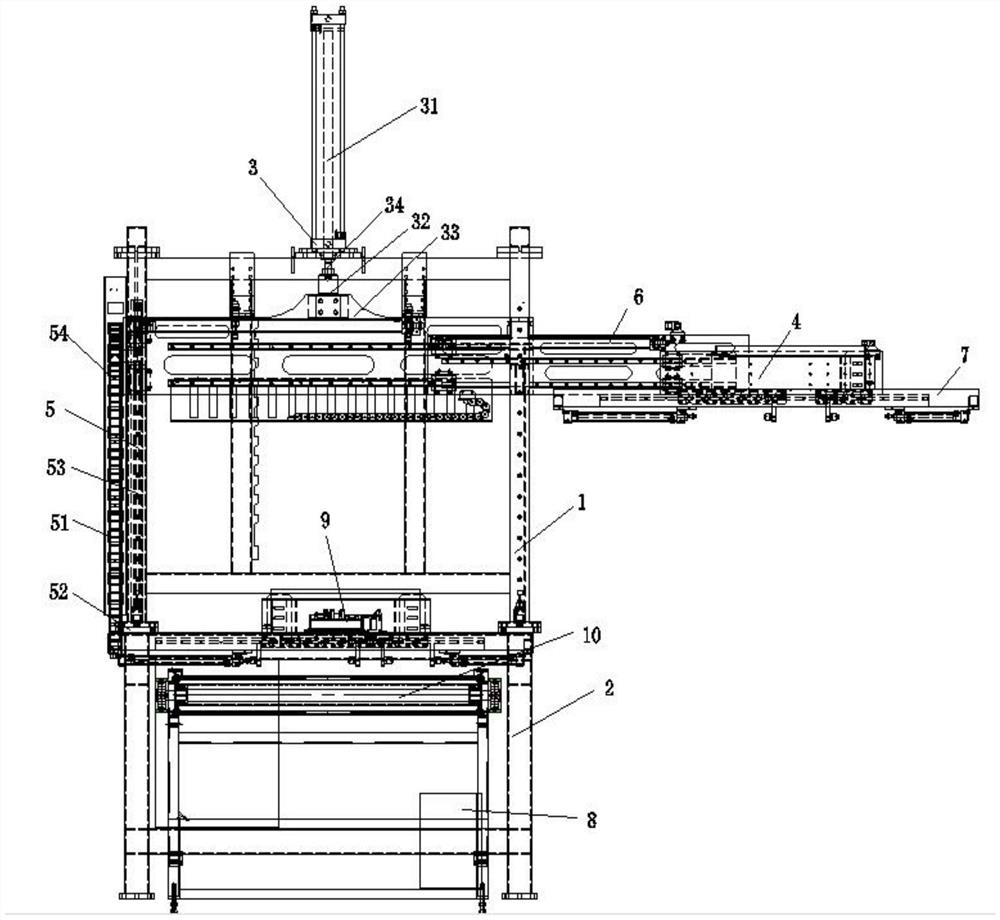

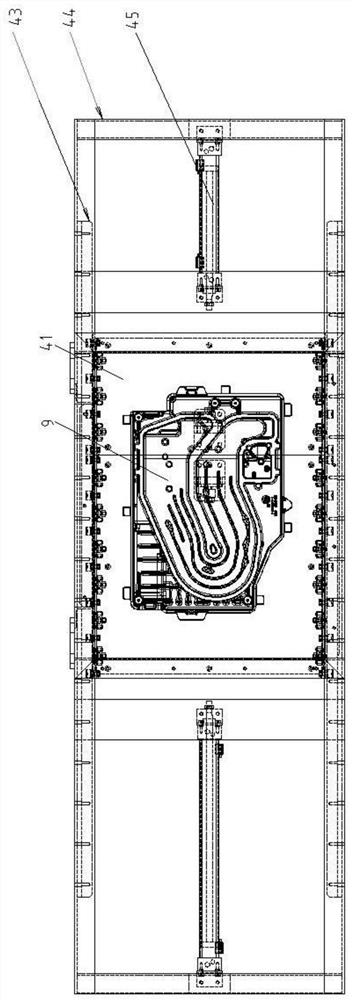

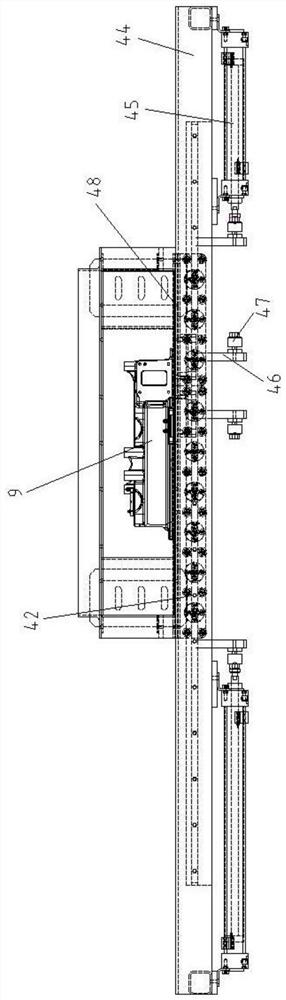

[0015] See Figure 1 to Figure 3 As shown, an automatic material receiving device for a hydraulic press has an upper welding frame 1 and a lower welding frame 2 connected thereto. The top of the upper welding frame 1 has a stamping mechanism 3, and a moving The material receiving tray assembly 4, the material receiving tray assembly 4 slides radially up and down on the upper welding frame 1 through the drag chain assembly 5, the material receiving tray assembly 4 is provided with a transverse guide rail 6, the material receiving tray The receiving tray 7 of the assembly 4 slides laterally on the guide rail 6, and the lower welding frame 2 is provided with a conveyor belt 10, and the driving belt 10 is used to catch the casting 9 falling from the receiving tray assembly 4. An electric control box 8 for controlling components is arranged in the welding frame 2 .

[0016] The punching mechanism 3 includes a vertical punching cylinder 31, a hydraulic buffer 32 and a hydraulic pun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap