Composite fabric and preparation method thereof

A composite fabric and composite layer technology, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc. The effect of improving the breaking strength and elongation at break, and increasing the adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

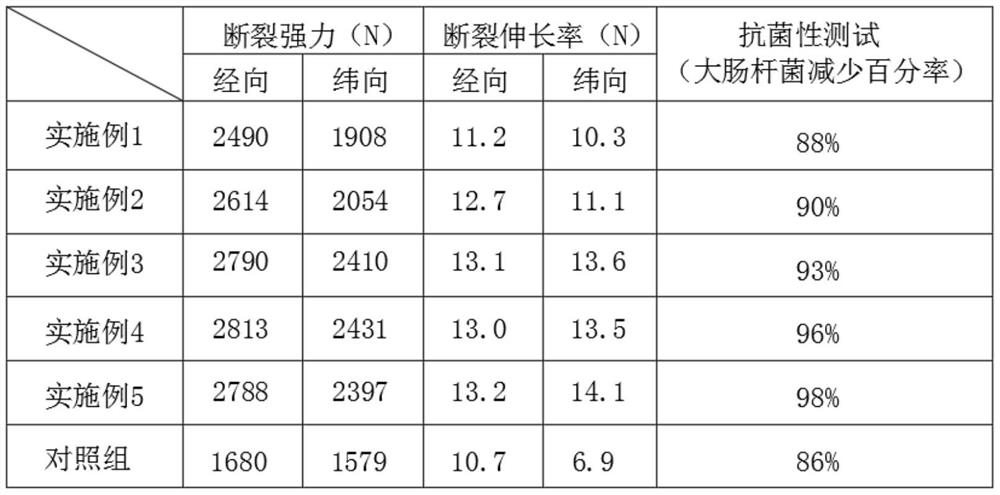

Examples

Embodiment 1

[0024] Weigh the components according to the following parts by weight: 12 parts of isocyanate, 0.1 part of dibutyltin dilaurate, 10 parts of polyether glycol, 3 parts of epoxy resin, 5 parts of amino-terminated polyether, 0.01 part of antioxidant, 10 parts of deionized water and 1 part of methyl ethyl ketone; isocyanate, dibutyltin dilaurate and polyether diol were mixed and reacted at 65° C. for 1.5 h under nitrogen atmosphere to obtain mixture A; Amino polyether, antioxidant, deionized water and methyl ethyl ketone were added to mixture A, and the modified coating was obtained after shearing and mixing at 2000r / min for 1 hour;

[0025] The components are weighed according to the following weight ratios: 0.5 wt % of silver nanoparticles, 10 wt % of zeolite, and 90 wt % of adhesive; after shearing and mixing the silver nanoparticles and zeolite for 1 h at high speed, The mixture of zeolite and the binder are fully mixed and stirred, and then the antibacterial coating is obtai...

Embodiment 2

[0028] Weigh the components according to the following parts by weight: 13 parts of isocyanate, 0.2 part of dibutyltin dilaurate, 11 parts of polyether glycol, 4 parts of epoxy resin, 6 parts of amino-terminated polyether, 0.02 part of antioxidant, 12 parts of deionized water, 1.5 parts of methyl ethyl ketone; isocyanate, dibutyltin dilaurate and polyether diol were mixed and reacted at a temperature of 65 ° C for 1.5 h under nitrogen atmosphere to obtain mixture A; Amino polyether, antioxidant, deionized water and methyl ethyl ketone were added to mixture A, and the modified coating was obtained after shearing and mixing at 2000r / min for 1 hour;

[0029] According to the ratio of 1:2, weigh zeolite and zirconium phosphate and mix to obtain the carrier;

[0030] The components are weighed according to the following weight ratios: 0.5 wt % of the silver nanoparticles, 10 wt % of the carrier, and 90 wt % of the binder; Fully mixing and stirring with the adhesive, and then vacuu...

Embodiment 3

[0033]Weigh the components according to the following parts by weight: 12 parts of isocyanate, 0.1 part of dibutyltin dilaurate, 10 parts of polyether glycol, 3 parts of epoxy resin, 5 parts of amino-terminated polyether, 0.01 part of antioxidant, 10 parts of deionized water and 1 part of methyl ethyl ketone; isocyanate, dibutyltin dilaurate and polyether diol were mixed and reacted at 65° C. for 1.5 h under nitrogen atmosphere to obtain mixture A; Amino polyether, antioxidant, deionized water and methyl ethyl ketone were added to mixture A, and the modified coating was obtained after shearing and mixing at 2000r / min for 1 hour;

[0034] The components were weighed according to the following weight ratios: 0.75wt% of silver nanoparticles, 14wt% of zeolite, and 93wt% of adhesive; The mixture of zeolite and the binder are fully mixed and stirred, and then the antibacterial coating is obtained after vacuuming to eliminate the bubbles in the mixture;

[0035] After washing the no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smudge thickness | aaaaa | aaaaa |

| Smudge thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com