Knitted mesh structure shirt fabric and preparation method thereof

A mesh structure and fabric technology, applied in knitting, weft knitting, rayon manufacturing and other directions, can solve the problems of lack of woven fabrics, such as lack of woven fabrics, non-hydrophilic and moisture absorption of chemical fibers, mercerizing holes and scratches, etc. Risk of pilling, tight and stable texture, and the effect of improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

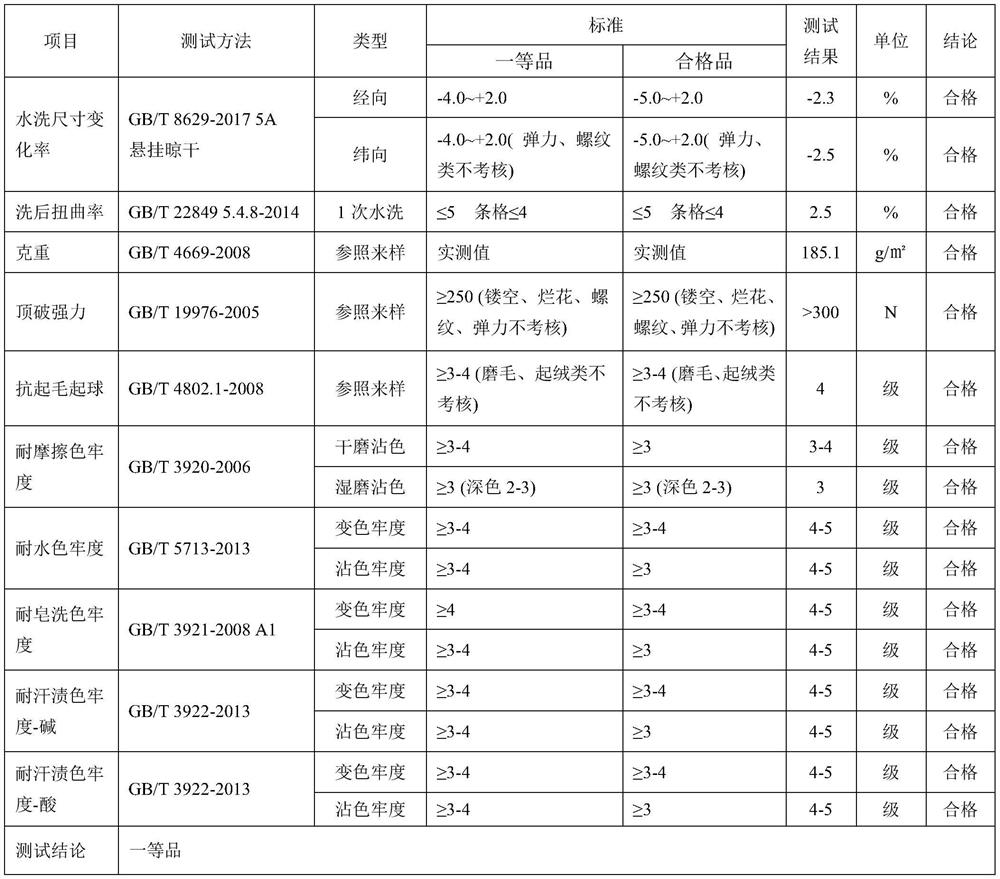

[0023] Embodiment 1: a kind of knitted mesh structure shirt fabric, including grammage is 190g / m 2 The fabric body is made of viscose-coated yarn and nylon single-hole yarn. The viscose-covered yarn is 75D viscose filament wrapped with 30D spandex yarn, and the nylon single-hole yarn is 30D / 1F nylon single-hole yarn. , The mass percentage of the fabric body is: 53% of viscose, 14% of spandex, and 33% of nylon.

Embodiment 2

[0024] Embodiment 2: the preparation method of the knitted mesh structure shirting fabric of embodiment 1, comprises the selection of yarn count raw material, weaving process, dyeing pre-treatment, dyeing process and post-setting shaping process, wherein:

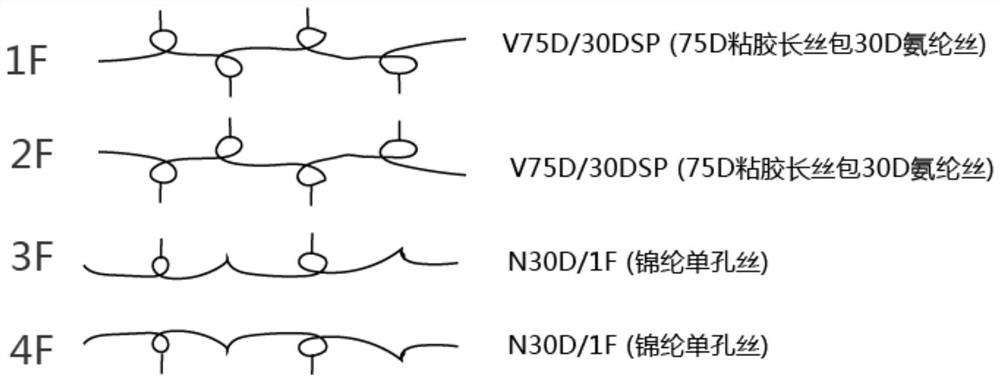

[0025] In the knitting process, use the 36G knitting double-sided circular machine to knit the fabric body. The knitting needles are arranged in the 1F and 2F to knit the interlock weave. The needle cylinder does not knit, and the needle disc forms loops and tucks to knit alternately. The knitting loop diagram is as follows figure 1 shown;

[0026] In the pre-dyeing treatment, pre-setting treatment is carried out on the gray cloth obtained by weaving first. The temperature of the pre-setting treatment is 190°C, the speed of the machine is 20m / min, the overfeed amount is 25%, and the expansion rate is 5%. Cleaning, refining and bleaching, rinsing to remove oil;

[0027] The dyeing process adopts a two-step dyeing method to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com