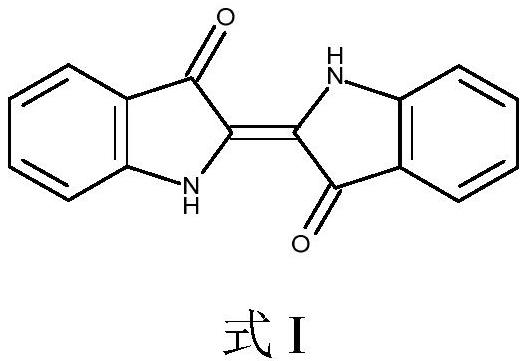

Process for dyeing textiles and enzymes used therein

A technology of textiles, tryptophanase, applied in the direction of dyeing, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of textiles - damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0119] According to some embodiments, for example, when the oxidase is mFMO and the cofactor regeneration enzyme is PTDH, the hybrid oxidase may comprise the fusion enzyme PTDH-mFMO, wherein mFMO and / or PTDH have been genetically modified to include cellulose binding domain (CBD).

[0120] According to some embodiments, the oxidative hybrid enzyme comprises an oxidase, a cellulose binding domain, and further comprises a cofactor regenerating enzyme, preferably PTDH.

[0121] According to some embodiments of the methods of the present invention, indole or indole derivatives can be converted to tryptophan or tryptophan derivatives in the presence of tryptophanase, and in the reaction catalyzed by tryptophanase, PLP can be used as a cofactor.

[0122] As mentioned above, enzymes (such as oxidases) can be modified to include certain binding domains, which are suitable for binding to the materials included in the textile to be dyed, and / or with respect to unmodified enzymes, incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com