Frog, preparation method thereof and railway turnout

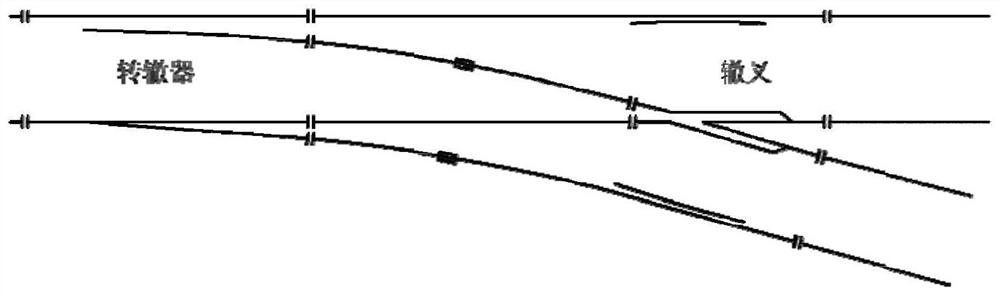

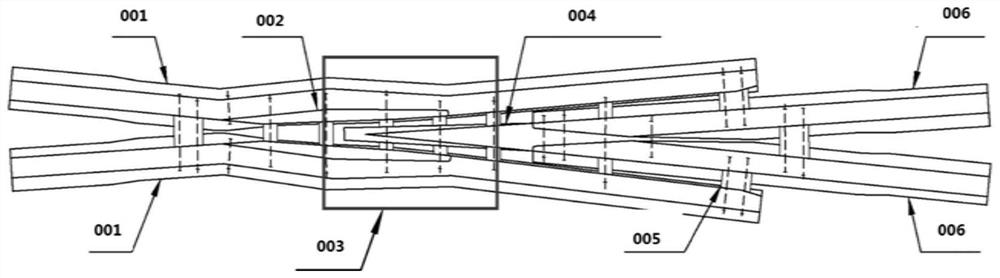

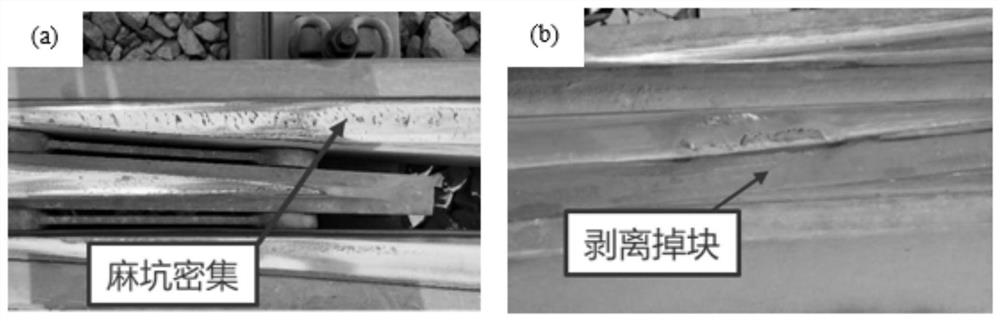

A frog and weld bead technology, used in tracks, roads, switches, etc., can solve the problems of no wheel-rail load transfer zone performance, difficult performance enhancement, improvement or optimization, etc. The performance of friction and wear, the effect of improving the online service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a kind of preparation method of frog, please refer to Figure 4 and Figure 5 , the space occupied by the additive area is reserved in the vertical direction of the original wing rail and the core rail, and the multi-layer structure is formed layer by layer on the substrate area through the additive manufacturing technology, and each layer structure is passed through the first welding wire Formed alternately with the second welding wire, the thickness of the multi-layer structure is controlled to 20mm, the rotation angle of two adjacent layers is roughly 20°, the bead width of the first welding wire is 1mm, and the bead width of the second welding wire is 3mm .

[0062] In terms of mass percentage, the chemical composition of the first welding wire is as follows: C 0.050%, Mo 1.50%, Si 0.50%, Ni 1.50%, Cr 0.5%, Mn 0.20%, Cu 0.10%, and the balance is Fe. In terms of mass percentage, the chemical composition of the second welding wire is as foll...

Embodiment 2

[0071] This embodiment provides a kind of preparation method of frog, please refer to Figure 4 and Figure 5 , the space occupied by the additive area is reserved in the vertical direction of the original wing rail and the core rail, and the multi-layer structure is formed layer by layer on the substrate area through the additive manufacturing technology, and each layer structure is passed through the first welding wire Formed alternately with the second welding wire, the thickness of the multi-layer structure is controlled to 50mm, the angle of rotation and staggering of two adjacent layers is roughly 90°, the bead width of the first welding wire is 1mm, and the bead width of the second welding wire is 2mm .

[0072] In terms of mass percentage, the chemical composition of the first welding wire is as follows: C 0.10%, Mo 3.50%, Si 1.00%, Ni 3.50%, Cr 1.00%, Mn 0.80%, Cu 0.50%, and the balance is Fe. In terms of mass percentage, the chemical composition of the second weldi...

Embodiment 3

[0081] This embodiment provides a kind of preparation method of frog, please refer to Figure 4 and Figure 5 , the space occupied by the additive area is reserved in the vertical direction of the original wing rail and the core rail, and the multi-layer structure is formed layer by layer on the substrate area through the additive manufacturing technology, and each layer structure is passed through the first welding wire Formed alternately with the second welding wire, the thickness of the multi-layer structure is controlled to 30mm, the angle of rotation and staggering of two adjacent layers is roughly 50°, the bead width of the first welding wire is 1mm, and the bead width of the second welding wire is 2mm .

[0082] In terms of mass percentage, the chemical composition of the first welding wire is as follows: C 0.10%, Mo 3.50%, Si 1.00%, Ni 3.50%, Cr 1.00%, Mn 0.80%, Cu 0.50%, and the balance is Fe. In terms of mass percentage, the chemical composition of the second weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com