a speed reduction mechanism

A technology of reduction mechanism and body, which is applied in the direction of mechanical equipment, components with teeth, gear lubrication/cooling, etc., can solve the problems of large size of the reducer, facilitate installation and transportation, improve stability, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is combined with the attached Figure 1-8 Further elaboration of this application.

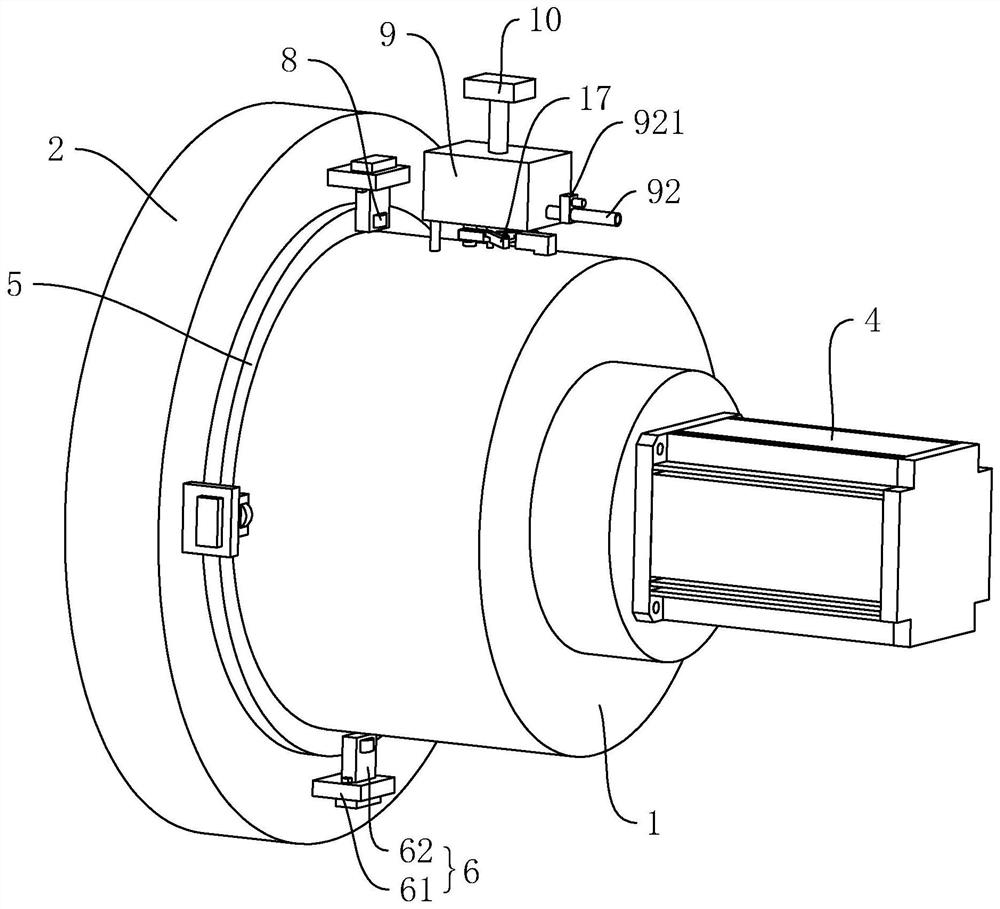

[0041] Embodiments of the present application disclose a deceleration mechanism. See Figure 1 The deceleration mechanism includes the fuselage 1 and the rotating wheel 2, the rotating wheel 2 is located on the side of the horizontal direction of the fuselage 1 and the rotating wheel 2 is connected to the fuselage 1, and the rotation axis of the rotating wheel 2 is set horizontally.

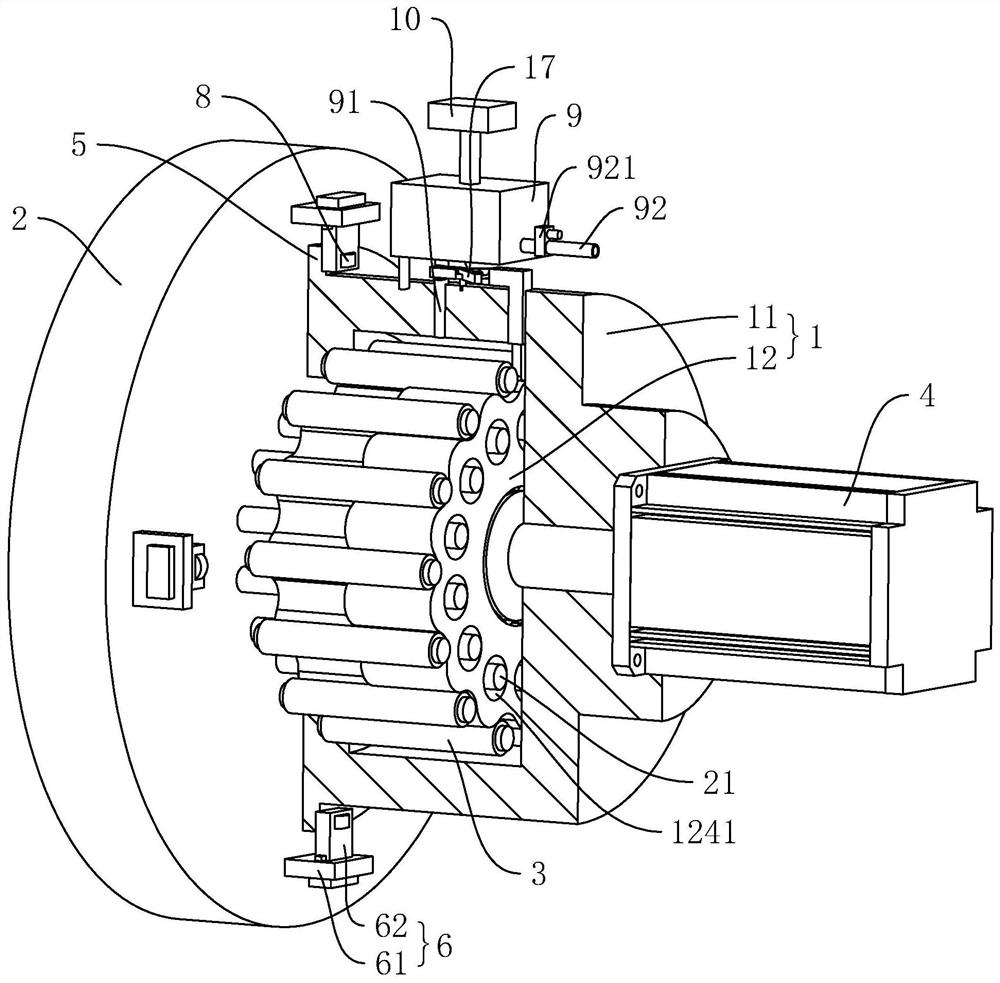

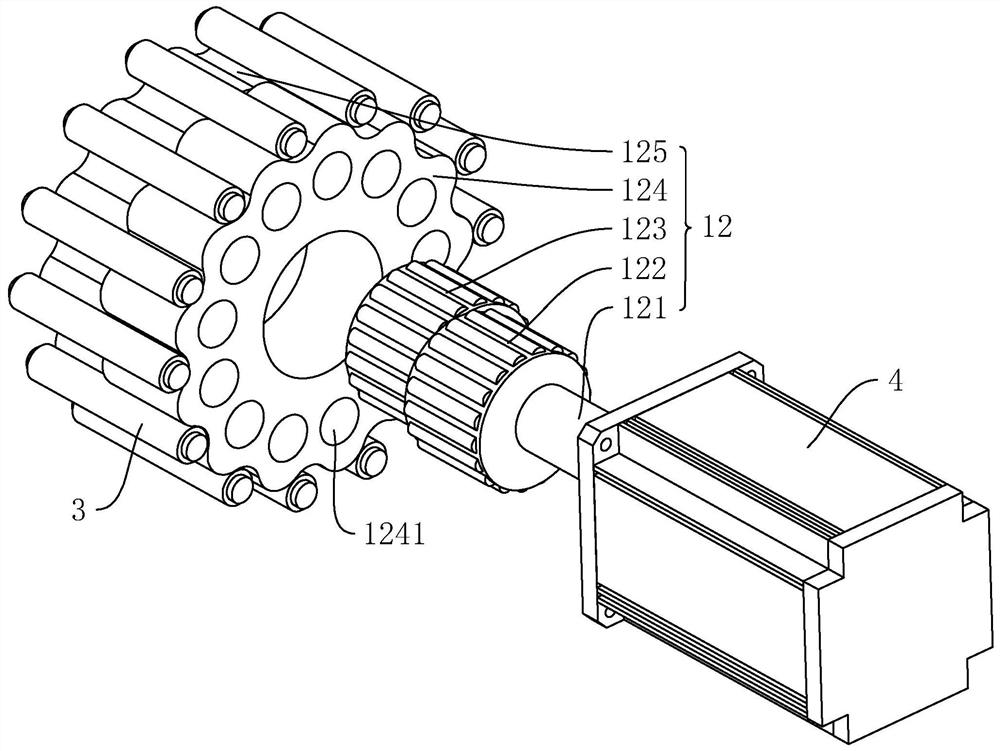

[0042] See Figure 2 and Figure 3, the fuselage 1 includes housing 11 and transmission assembly 12, the inner wall of the housing 11 is fixed with a number of needle tooth pins 3, a number of needle tooth pins 3 along the rotation axis of the rotating wheel 2 in a circumferential uniform interval distribution. Transmission assembly 12 is located in the housing 11, the transmission assembly 12 includes an input shaft 121, a first eccentric wheel 122, a second eccentric wheel 123, a first cycloidal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com