Louver-type air and material separating device

A separation device and 100-page technology, which are applied in the directions of drying gas arrangement, seed preservation by drying, drying machine, etc., to achieve the effect of increasing ventilation area, reducing manufacturing cost and increasing bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

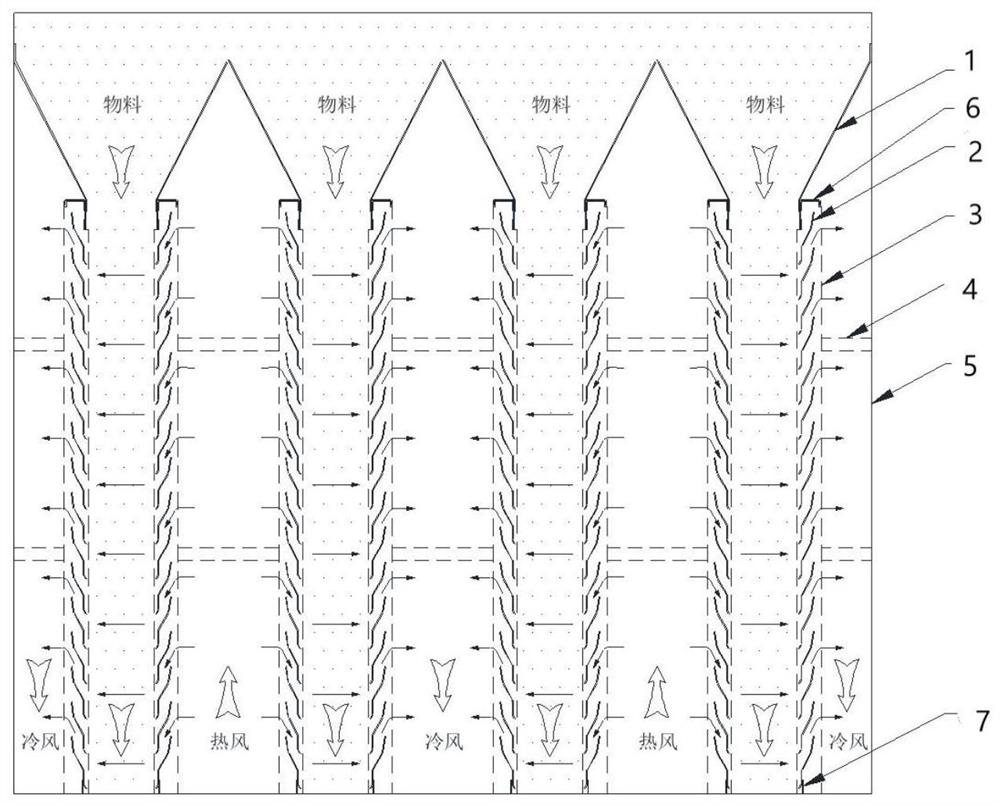

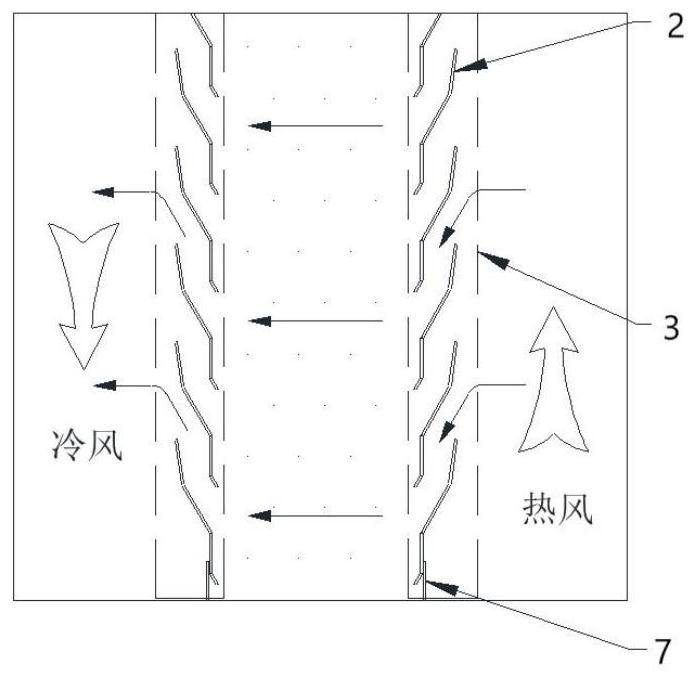

[0015] Such as Figure 1-2 As shown, the present invention discloses a louver-type air separation device, which is applied to a grain dryer, and is characterized in that: the louver-type air separation device includes a material guide plate 1 , louver blade 2, louver support plate 3, reinforcing rib 4, housing 5, upper material baffle 6, lower material baffle 7; the louver 2 is overlapped and fixed on the louver support plate 3 with a certain The gap is combined to form a separation plate, which is installed symmetrically to separate the grain passage and the cold and hot air passages; during the working process of the grain dryer, the material flows from the top to the bottom and enters the grain passage under the action of the material gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com