Lithium ion battery, preparation method and battery pack

A lithium-ion battery and electrolyte technology, which is applied in battery pack parts, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of reducing battery energy density, tabs occupying space and weight, affecting battery quality and FTY, etc. , to achieve the effects of increased volumetric energy density, easy battery safety, and guaranteed battery safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The following is the preparation method of the above-mentioned lithium-ion battery:

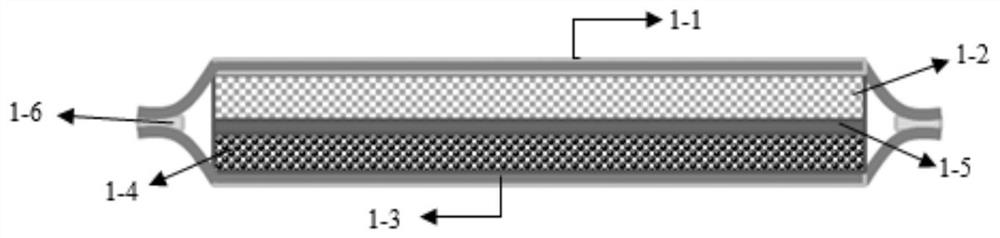

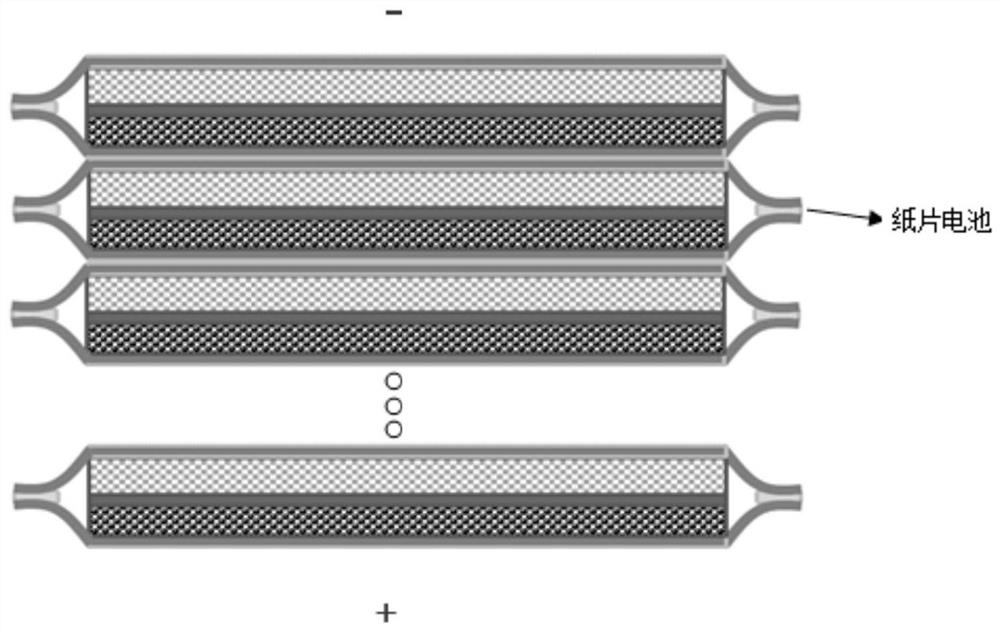

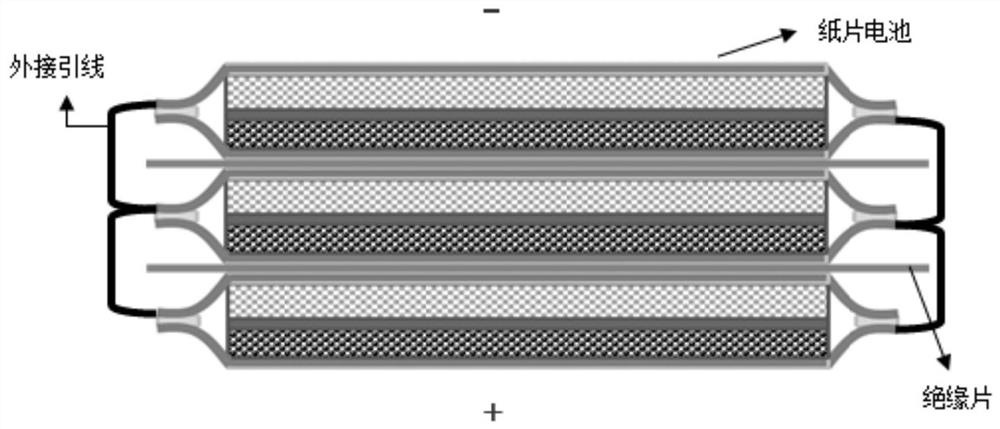

[0049] Prepare the positive electrode sheet with a thickness of 100-600um and the negative electrode sheet with a thickness of 100-600um, stack the sheets first and then package them around in the order of the positive electrode sheet, separator and negative electrode sheet. 1-1 / negative current collector 1-3 and active material layer, i.e. positive electrode active material layer 1-2 / negative electrode active material layer 1-4, to obtain a lithium ion battery (such as figure 1 ). The lithium-ion battery shell is not only the encapsulation layer, but also the current collector. The positive current collector can be Al with a thickness of 14-200um, and the negative current collector can be Cu, Ni, Cu / Al with a thickness of 8-150um. In addition, positive / The negative current collector can also be an organic current collector made of conductive polymer. In order to improve the combina...

Embodiment 1

[0060] Add 42.43g of LFP and 1.31g of Ketjen Black into the mixing tank for pre-mixing for 10min, then add 13.47g of electrolyte solution and vacuum dry mix for 10min (turn on the cooling water, keep the temperature <10°C), mold it, and transfer it to a 20um thick On the Al foil, cut the positive electrode sheet; add 20.20g of graphite and 0.31g of conductive carbon black to the mixing tank for pre-mixing for 10min, then add 7.15g of electrolyte solution and vacuum dry mix for 10min (turn on the cooling water and keep the temperature <10°C). Mold forming, transferred to Cu foil with a thickness of 10um, and cut to obtain the negative electrode sheet; stacked together in the order of positive electrode sheet, separator, and negative electrode sheet; using MPP / PP / MPP film with a thickness of 30um / 50um / 30um at 185°C Heat sealing for 5s to realize packaging; the final battery is obtained after leveling.

Embodiment 2

[0062] Add 42.43g of LFP and 1.31g of Ketjen Black to the mixing tank for pre-mixing for 10min, then add 16.46g of electrolyte and vacuum dry mix for 10min (turn on the cooling water and keep the temperature <10°C), mold it, and transfer it to a 20um thick On the Al foil, cut the positive electrode sheet; add 20.20g of graphite and 0.31g of conductive carbon black to the mixing tank for pre-mixing for 10min, then add 8.80g of electrolyte solution for vacuum dry mixing for 10min (turn on the cooling water, keep the temperature <10°C), and Mold forming, transferred to Cu foil with a thickness of 10um, and cut to obtain the negative electrode sheet; stacked together in the order of positive electrode sheet, separator, and negative electrode sheet; using MPP / PP / MPP film with a thickness of 30um / 50um / 30um at 185°C Heat sealing for 5s to realize packaging; the final battery is obtained after leveling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com