Control method and control device of flyback converter

A technology of a flyback converter and a control method, which is applied in output power conversion devices, control/regulation systems, conversion of DC power input to DC power output, etc., can solve problems such as flyback converter losses and reduce switching. Loss, cost reduction, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

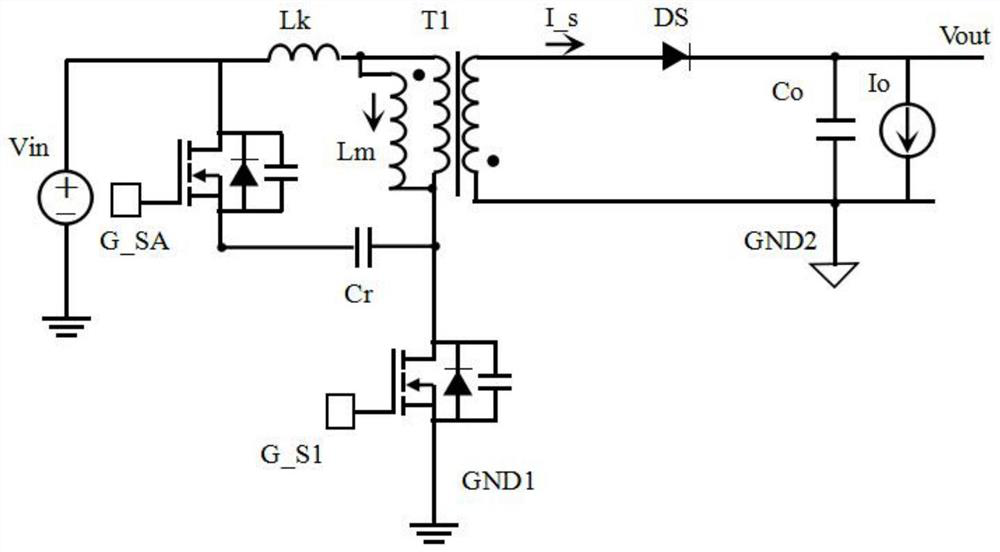

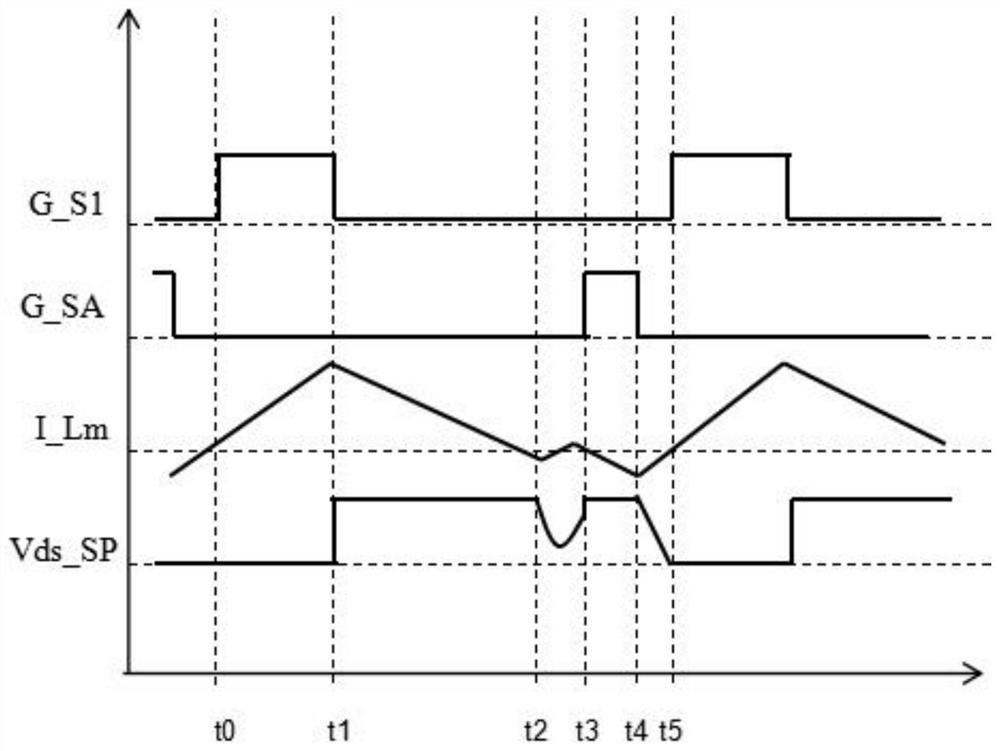

[0075] image 3 It is the circuit schematic diagram of the flyback converter of the first embodiment of the present invention, image 3 The flyback converter comprises a primary side main power switch unit 250, a secondary side switch rectifier unit 230, a transformer T1, a clamp circuit 204, a feedback circuit 243, an output capacitor Co and the control device of the present invention; the control device includes a primary side The controller 240, the isolation circuit 241, the secondary side controller 242 and the feedback circuit 243; the primary side controller 240 detects the input voltage to generate the input voltage detection signal Vin_s, and the feedback circuit 243 detects the output power to generate the output power detection signal FB and outputs it to the primary side The controller 240, the primary side controller 240 generates a control signal SW according to the input voltage detection signal Vin_s and the output power detection signal FB, and controls the open...

no. 2 example

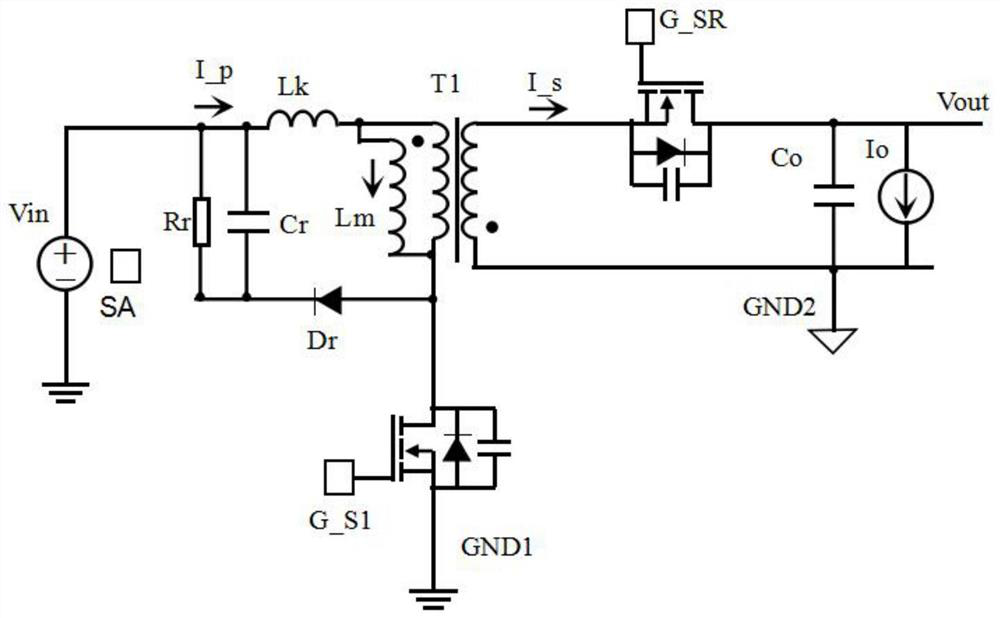

[0096] Figure 6 It is the circuit schematic diagram of the flyback converter of the second embodiment of the present invention, Figure 6 The difference from the first embodiment is that the second embodiment judges the working mode of the flyback converter through two signals, namely, the input voltage detection signal Vin_s and the output power detection signal FB.

[0097] Such as Figure 7 Shown is the flow chart of the switching method of the second implementation of the present invention: when the input voltage detection signal Vin_s is greater than or equal to the first threshold Vth_vin1, and the output power detection signal FB is greater than or equal to the second threshold Vth_vo1, the flyback converter works at the first threshold A working mode; otherwise, when the input voltage detection signal Vin_s is smaller than the first threshold Vth_vin1 or the output power detection signal FB is smaller than the second threshold Vth_vo1_, the flyback converter works in...

Embodiment 2

[0098] Embodiment 2 The schematic diagrams of the waveforms of the first working mode and the second working mode are the same as those in the first embodiment, and each cycle in the first working mode is also divided into four stages, which are the same as those in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com