Double-weighing moisture regaining method for cigar core tobacco leaves

A cigar, double weighing technology, applied in the fields of tobacco, tobacco preparation, measuring device, etc., can solve the problems of inability to accurately control the moisture content of tobacco leaves, large losses of tobacco leaves after repeated tossing, and increase production costs, and achieves prevention of mildew in tobacco leaves. Simple and convenient operation, high moisturizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

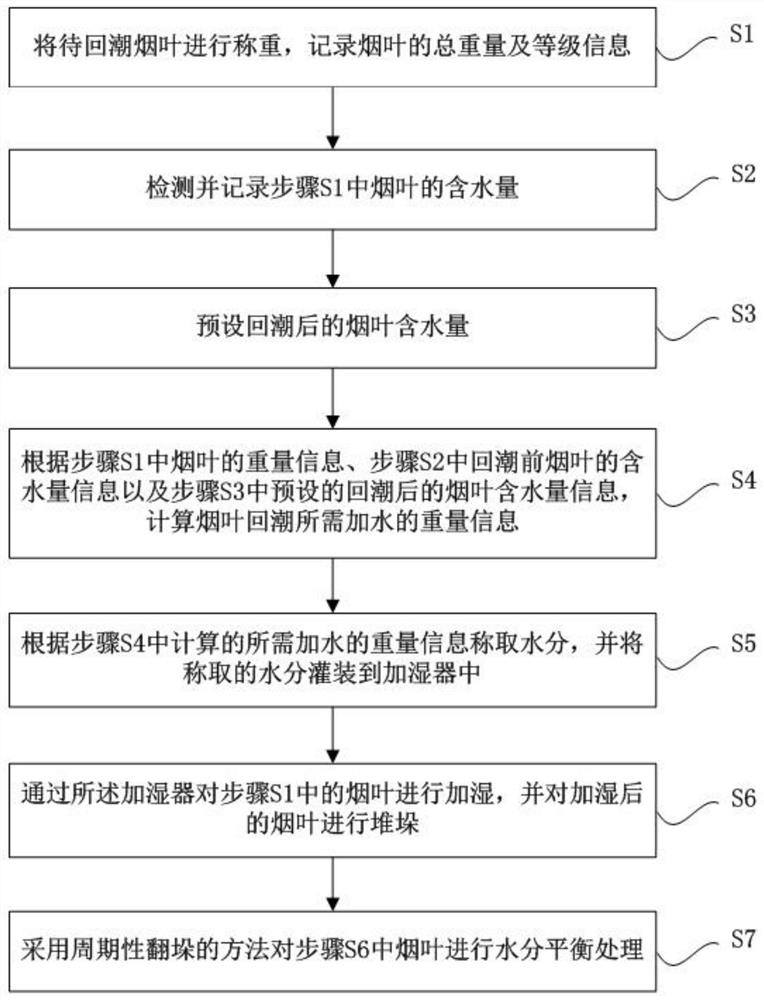

[0030] like figure 1 As shown, the present embodiment provides a double-weighing moisture regain method for cigar filler tobacco leaves, comprising the following steps:

[0031] Step S1, weighing 200 kg of middle leaf tobacco leaves of the filler variety CX-014 to be rehydrated, and carrying out wooden box fermentation (box type fermentation) after the moisture resurgence is planned;

[0032] Step S2, testing the moisture content of the tobacco leaves before fermentation. For the weighed tobacco leaves described in step S1, randomly select 20 tobacco leaves, randomly select 2 representative tobacco leaves from each tobacco, and take 2g of mesophyll on both sides of the main vein in the middle of the leaf , use an infrared moisture detector to detect moisture; detect the moisture content of the tobacco leaves, the weighted average middle leaf is 20.5%, and the upper leaf is 22.6%, and record the moisture content of the tobacco leaves before fermentation;

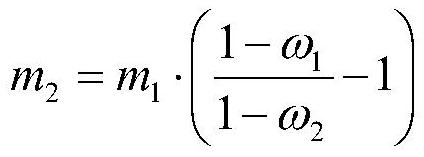

[0033] Step S3, pres...

Embodiment 2

[0056] In this example, the double-weighing moisture resurgence method in Example 1 is adopted in the fermentation process of the cigar filler variety CX-014 tobacco leaves. The moisture resurgence is in the free space of the tobacco leaf warehouse, with an area of about 80m2 2 .

[0057] The control group is the 12kg / h industrial humidifier atomization resurgence method. In the idle warehouse, a 2m high, 15m long, and 5m wide resurfacing shed is built with bamboo poles, and the surrounding and top are sealed with 8m wide film enclosures and sealing glue. ; Tobacco leaves are 1m away from the top humidifying pipe, and 0.8m away from the surrounding film walls.

[0058] The experimental design, quantity, etc. are shown in Table 2, and the remaining steps and operation methods are the same as in Example 1.

[0059] Table 2 Design of cigar filler tobacco leaf regain moisture test

[0060]

[0061] The resurgence results are shown in Table 3 below:

[0062] Table 3 Compari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com