Device and method for preparing metal semi-solid material

A semi-solid, fixed device technology, used in stirring devices, lighting and heating equipment, furnaces, etc., can solve the problems of high technical difficulty, high cost, and many dendrites in forming complex parts, reducing the amount of mechanical processing, Good quality, small solidification shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

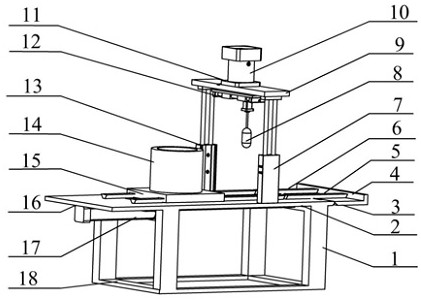

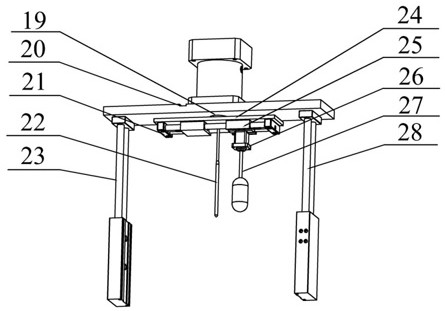

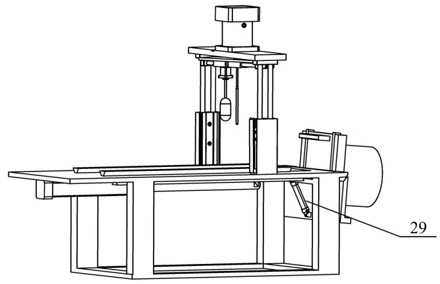

[0027] This embodiment provides a device for preparing metal semi-solid materials, including a fixing device, a transfer device, a mechanical stirring device and a pouring device, the fixing device is used to install the transfer device, a mechanical stirring device and a pouring device; the transfer device is used to store and move Melt metal; mechanical stirring device for stirring molten metal; pouring device for pouring molten metal.

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , The fixing device includes a stainless steel base bracket 1, a stainless steel base top plate 2 and a base bottom plate 18 welded together to form an integral body.

[0029] The transfer device includes the first dovetail slideway 5, the second dovetail slideway 6, the material storage tank 14, the material tank fixing seat 15, the cylinder fixing plate 16, the third cylinder 17, and the material storage tank 14 is fixed on the material tank fixing seat 15. On the first dovetai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com