a b 4 si and b 6 Si purification method

A purification method and solution technology, applied in the field of materials, can solve problems such as complex process, limited purity improvement, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

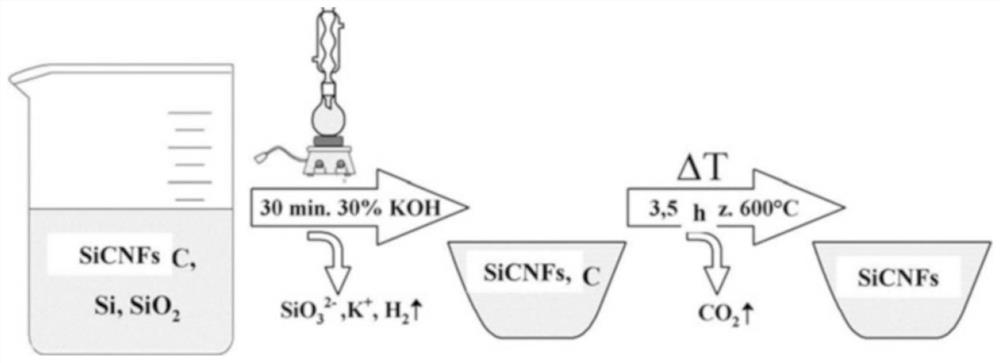

[0057] B 4 Si purification process:

[0058] 1. The medicines and reagents used in this example are shown in the following table:

[0059] Table 1 Table of experimental drugs and reagents

[0060]

[0061] 2. The instruments used are shown in Table 2:

[0062] Table 2 Experimental instrument table

[0063]

[0064] In addition, other materials used in the experiment are from chemical agencies, such as disposable plastic droppers, plastic graduated cylinders (500mL and 250mL), nitrile gloves, magnetic stirring bars, Buchner funnels, aqueous / organic microporous filtration Membrane, medium-speed / slow-speed quantitative analysis filter paper, sand core funnel, etc.; all preparation solutions and reactions are deionized water; polytetrafluoroethylene beakers (250mL and 500mL), stirring bars, from custom.

[0065] 3. B 4 Si process exploration experiment

[0066] 3.1 Separation by filtration

[0067] In order to purify the processed B 4 Si is effectively separated from...

Embodiment 2

[0139] B 6 Si purification process:

[0140] The instruments and equipment used in this example are the same as those in Example 1, and the purification process exploration is the same as that in Example 1.

[0141] 1. This embodiment B 6 Si experimental process:

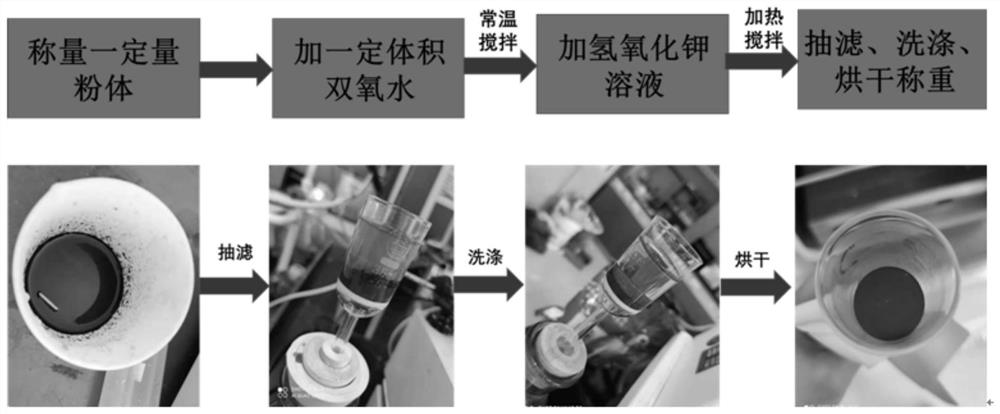

[0142] Since this example found in the previous research that B 6 The reaction is relatively stable after adding hydrogen peroxide to the original Si powder, but after adding KOH, a large number of bubbles are generated in the system, mainly because the impurity components Si and B in the powder are less, and the hydrogen peroxide is excessive, and reacts with KOH to generate oxygen . Based on this, in this embodiment, an optimization process is performed (as shown in the optimized experimental process flow and sample diagram in FIG. 10 ), and factors are investigated to obtain the best process.

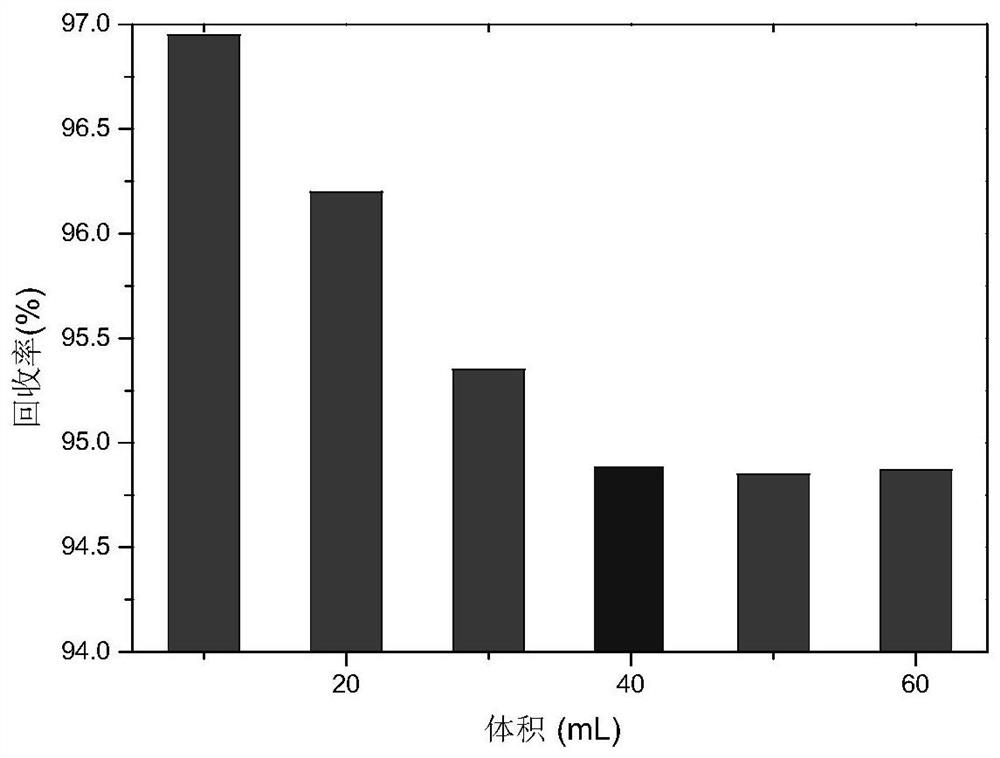

[0143] 1.1. Hydrogen peroxide dosage optimization (3mL, 5mL, 10mL, 15mL, 20mL, 25mL)

[0144] Considering that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com