Method for purifying TaSi2 powder

A purification method and powder technology, applied in the field of materials, can solve the problem that toxic gases are difficult to popularize and apply

Pending Publication Date: 2021-07-23

HARBIN INST OF TECH +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0041] TaSi in this example 2 The powder purification method is as follows:

[0042] 1. Experimental equipment:

[0043] The instruments used are shown in Table 1:

[0044] Table 1 Table of experimental instruments

[0045]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

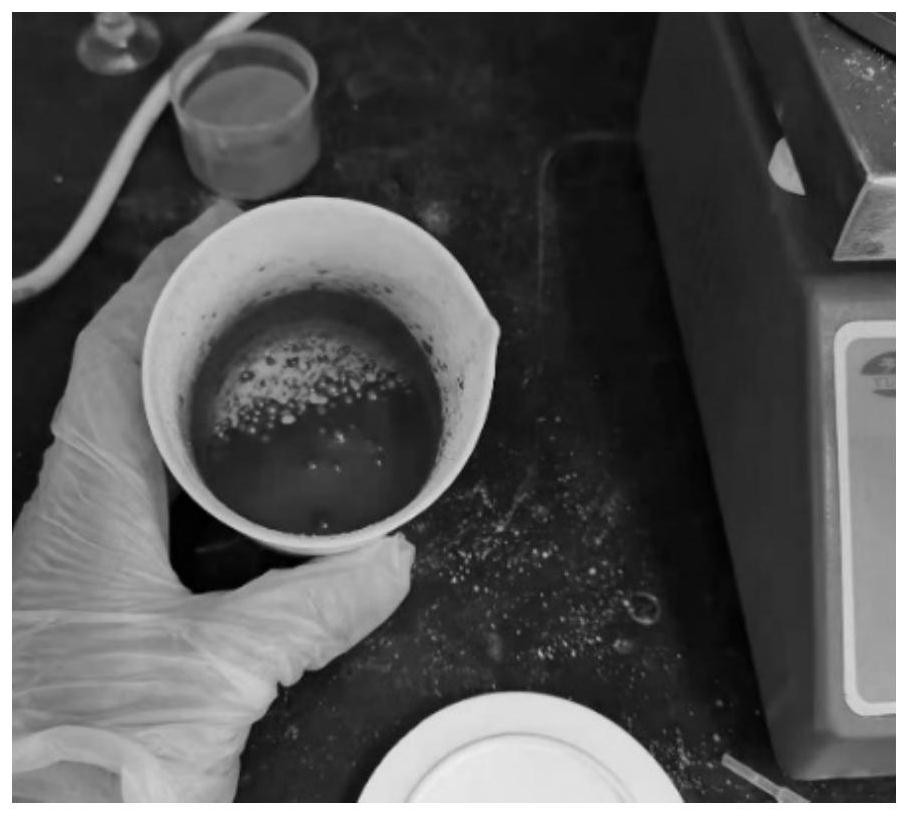

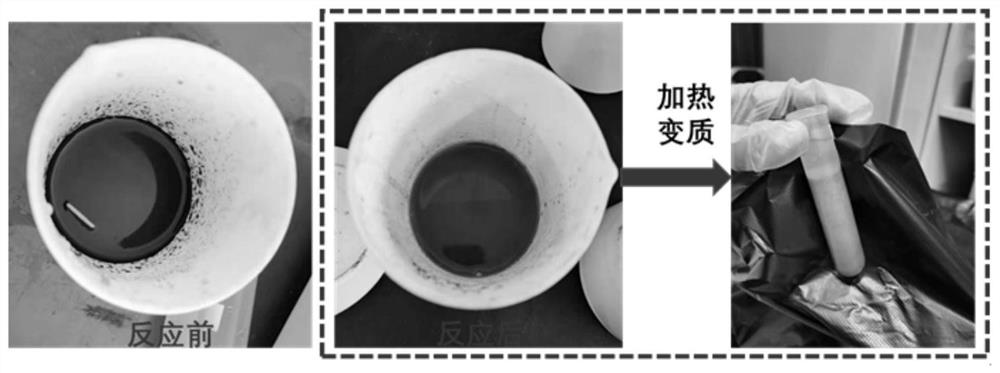

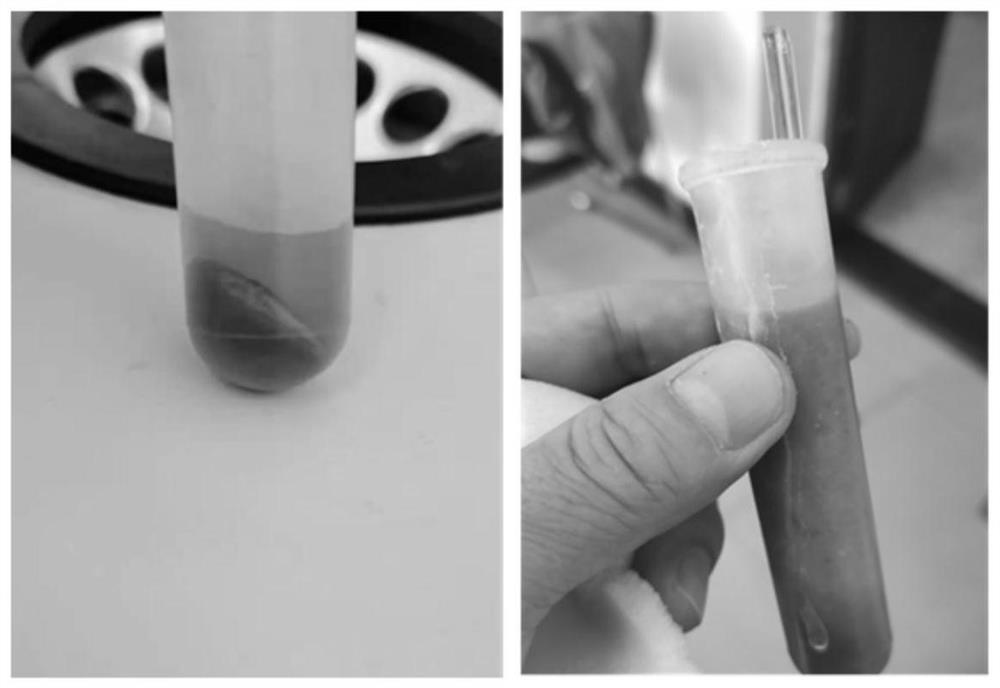

The invention discloses a method for purifying TaSi2 powder, relates to the field of materials, and aims to provide a method for purifying TaSi2 powder, which is economical, easy to implement and good in purification effect. The method comprises the following steps: taking TaSi2 raw powder, adding a KOH solution with the concentration of 1-5 mol / L, carrying out stirring reaction in a water bath kettle at the room temperature to 90 DEG C for 2-10 hours, then carrying out suction filtration by using a sand core funnel, washing to be neutral by using ultrapure water, and carrying out vacuum drying to obtain purified TaSi2 powder, wherein the mass volume ratio of the TaSi2 raw powder to the KOH solution is 1g: (10-50) mL. From the perspective of economy and easy implementation, the invention provides the following purification treatment process: the purification effect is achieved through a series of treatment. The method is applied to the field of TaSi2 powder.

Description

technical field [0001] The invention relates to the field of materials, in particular to a TaSi 2 Powder purification method. Background technique [0002] TaSi 2 It has excellent properties such as high melting point, low resistivity, corrosion resistance, high temperature oxidation resistance, and good compatibility with silicon, carbon and other substrate materials. It can be used as a coating for some circuit components or parts of some high temperature structures. Its preparation process usually uses high-purity metal Ta and Si as raw materials, which are heated at high temperature in a hydrogen atmosphere. Therefore TaSi 2 The raw powder has high purity, but there are also trace impurities, which are unreacted Ta and Si, etc. Therefore, the purification treatment of the powder is mainly for Ta, Si, SiO 2 and Ta 2 o 5 The effective removal of SiO 2 and Ta 2 o 5 content is very small. [0003] There are many reports on the chemical removal methods of the above...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B33/06

CPCC01B33/06C01P2002/72C01P2006/80

Inventor 李明伟董国华张庆猛钟业盛杨剑民陈均优孙宇雷史丽萍赫晓东张文治何飞

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com