Partially coated honeycomb steel-concrete composite beam and manufacturing method thereof

A production method and concrete technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of not giving full play to the efficiency of the beam section, increasing the prefabrication cycle, and poor combination, so as to save the cost of fire protection and anticorrosion, and improve the bending resistance The effect of high force and cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

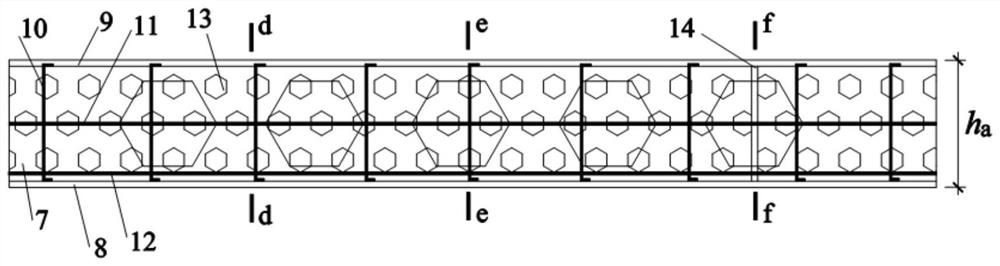

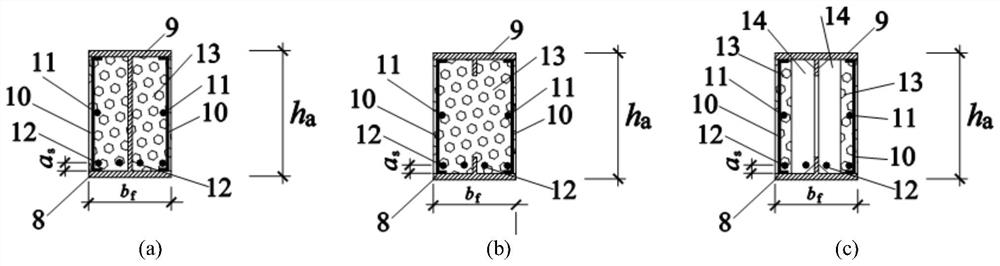

[0040] refer to figure 1 and figure 2 , a partially clad honeycomb steel-concrete composite beam, including honeycomb steel, the honeycomb steel is H-shaped steel with hexagonal holes in the web, and a set distance is arranged between the two flanges of the honeycomb steel. The C-shaped connecting rod is formed, the longitudinal reinforcement is arranged near the honeycomb steel tension flange, the waist reinforcement and the outer longitudinal reinforcement pass through the C-shaped connecting rod and are bound on the C-shaped connecting rod, the hole and the honeycomb Both sides of the steel web are filled with concrete.

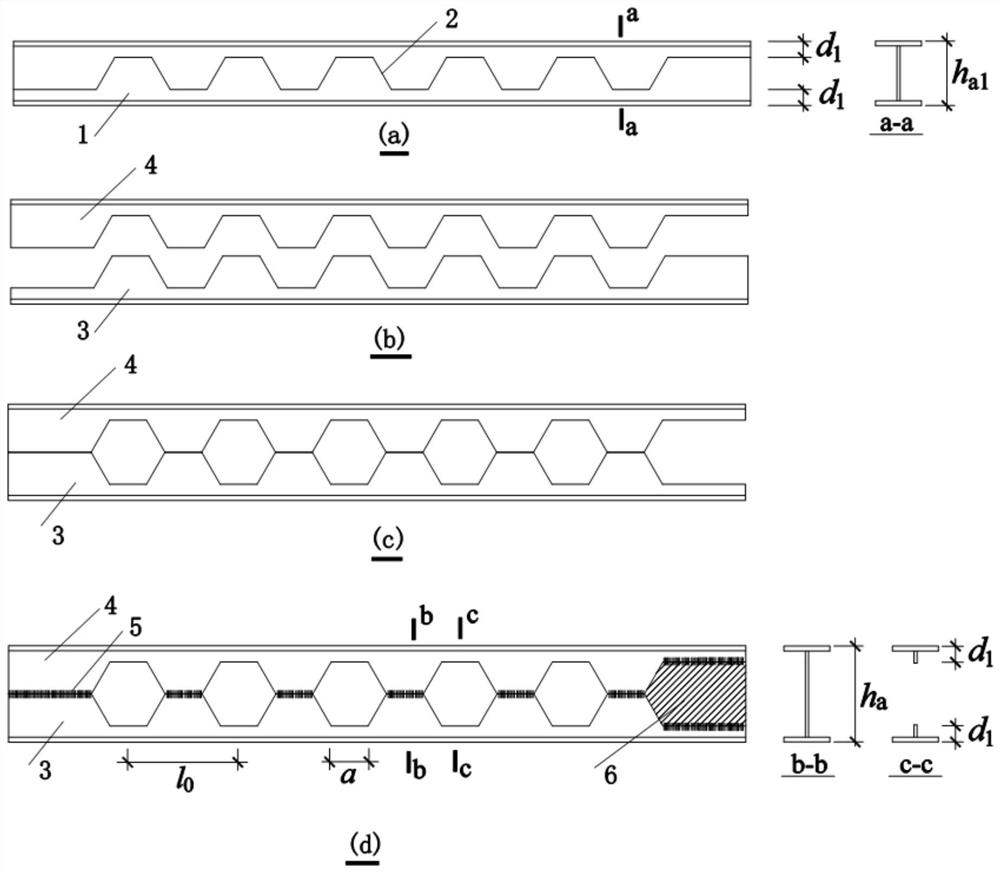

[0041] The H-shaped steel 1 of the present invention is divided into two parts according to the continuous zigzag cutting line 2 with a numerical control cutting machine: the lower half 3 and the upper half 4, and the lower half 3 is turned hori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com