Aluminum alloy torsion cable for wind power generation and crimping method

An aluminum alloy and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of low strength and elongation of aluminum conductors, poor strength and softness of aluminum conductors, and inability to withstand shearing forces, etc., to achieve processing The process is simple and feasible, the weight of the cable is reduced, and the effect of improving the tensile and load-bearing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

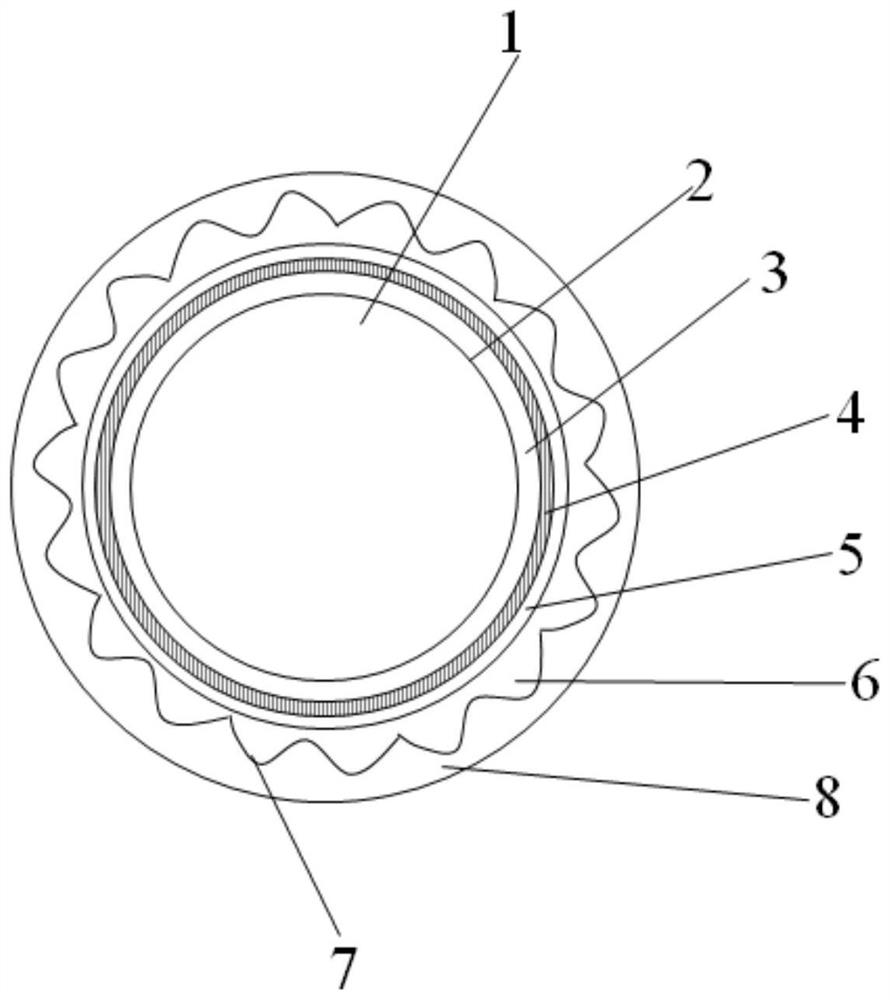

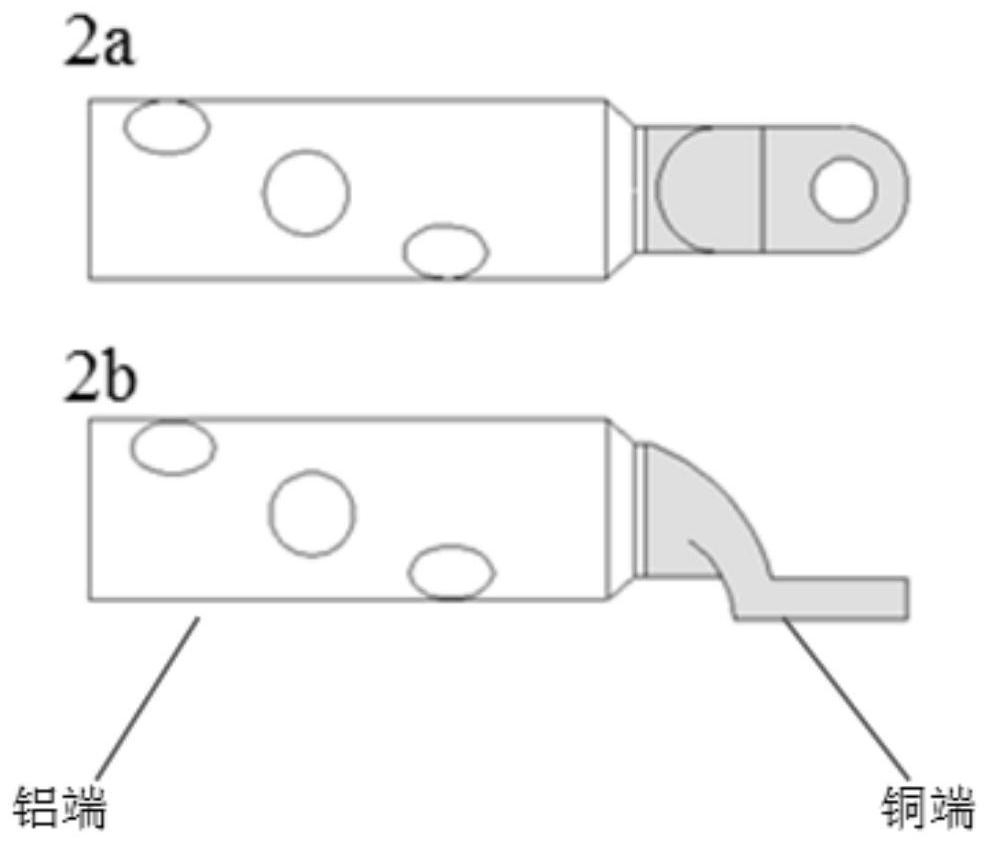

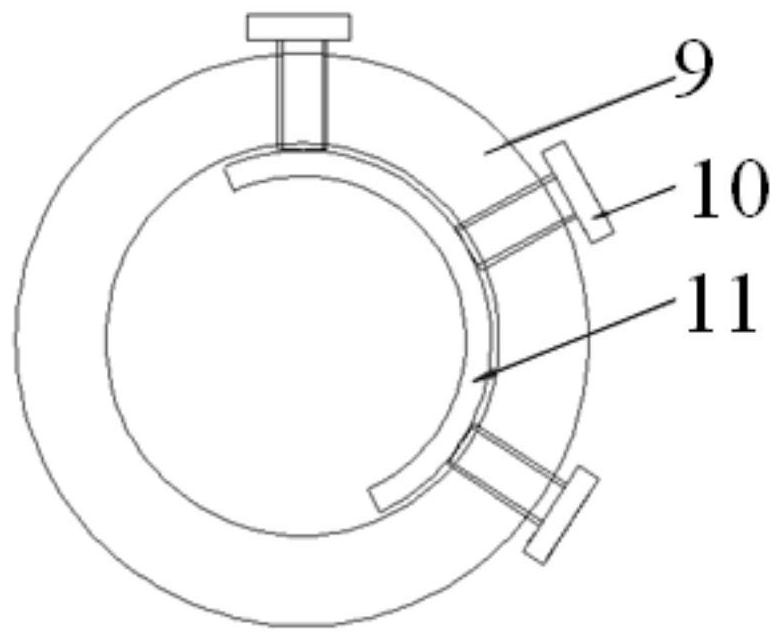

[0024] Such as Figure 1-3 As shown, an aluminum alloy torsion cable for wind power generation includes an aluminum alloy torsion cable and connecting terminals; the aluminum alloy torsion cable includes a main core conductor 1, a reinforced non-woven fabric layer 2, a waterproof adhesive Layer 3, insulating layer 4, metal wire braided shielding layer 5, inner sheath 6 and outer sheath 8, and the reinforced non-woven fabric layer 2 is closely connected with the insulating layer 4 and other layers outside it through the waterproof adhesive layer 3 Combined, it has good waterproof performance at the same time, avoiding the conductor from entering water and affecting normal use. The outer side of the inner s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com