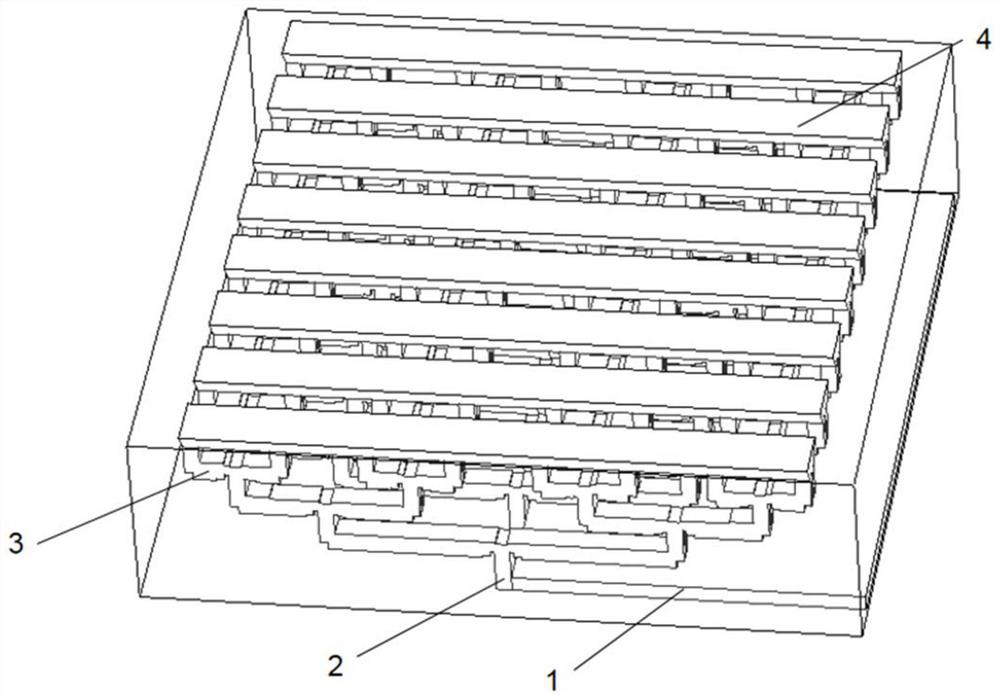

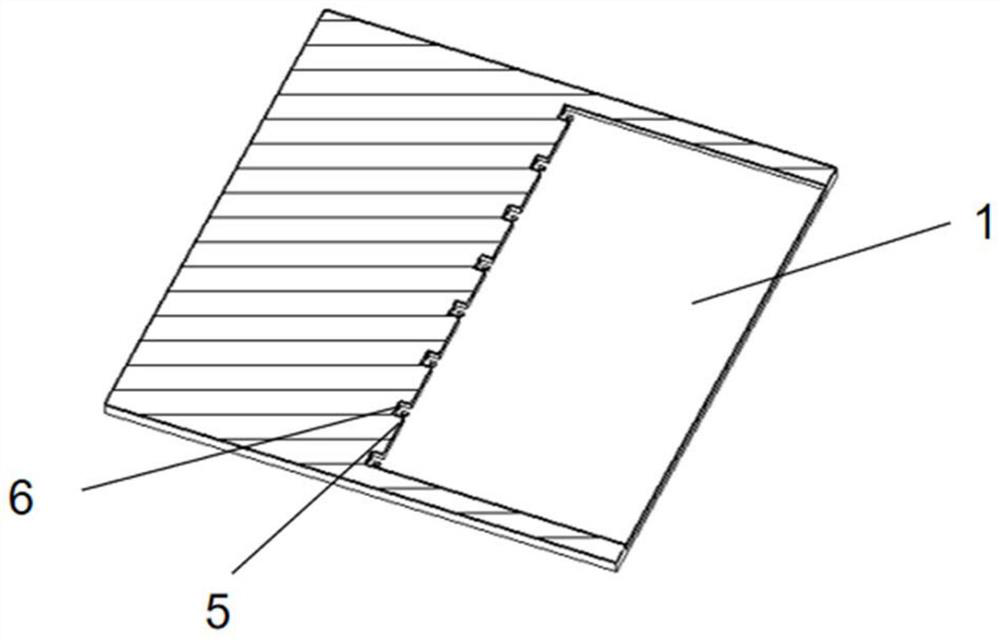

A multilayer ridged waveguide antenna feed structure

An antenna feeding and waveguide structure technology, which is applied to linear waveguide feeding arrays, antennas, antenna arrays, etc., can solve the problems of difficult processing and assembly, complicated boundary shapes of ridge waveguides, etc., and achieves high power capacity and easy expansion of the antenna aperture. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

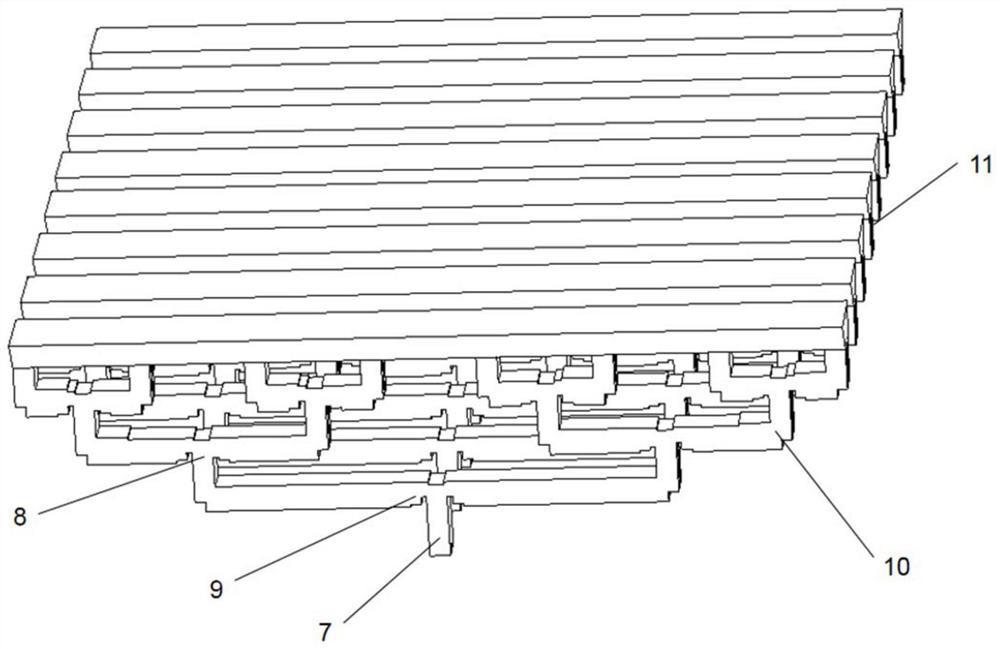

[0052] Since the present invention works in the microwave and millimeter wave frequency band, the influence of the loss of the transmission line needs to be considered in the design process, so the waveguide structure is used as the main structure of the transmission line for design. In a certain frequency band, when the frequency remains unchanged, different waveguide heights will lead to different propagation constants and different waveguide characteristic impedances. Therefore, we can design an equal power divider with lower loss and a different waveguide height by changing the waveguide height. Equal power divider, which forms the H-plane power distribution structure of the ridged waveguide that we show. At the same time, since the antenna gain increases with the increase of the antenna output aperture, multiple ridge waveguide H-plane power distribution structures can be stacked one after the other, each layer can correspond to the radiation structure of a line array, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com