Electrolytic machining device for special-shaped thin-walled curved surface parts

A technology for curved surface parts and processing devices, which is applied in the field of electrolytic machining devices for special-shaped thin-walled curved surface parts, can solve the problems of deformation and non-displacement of parts, and achieves the effects of good technical flexibility, deformation prevention, and uniform current density distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with specific embodiments.

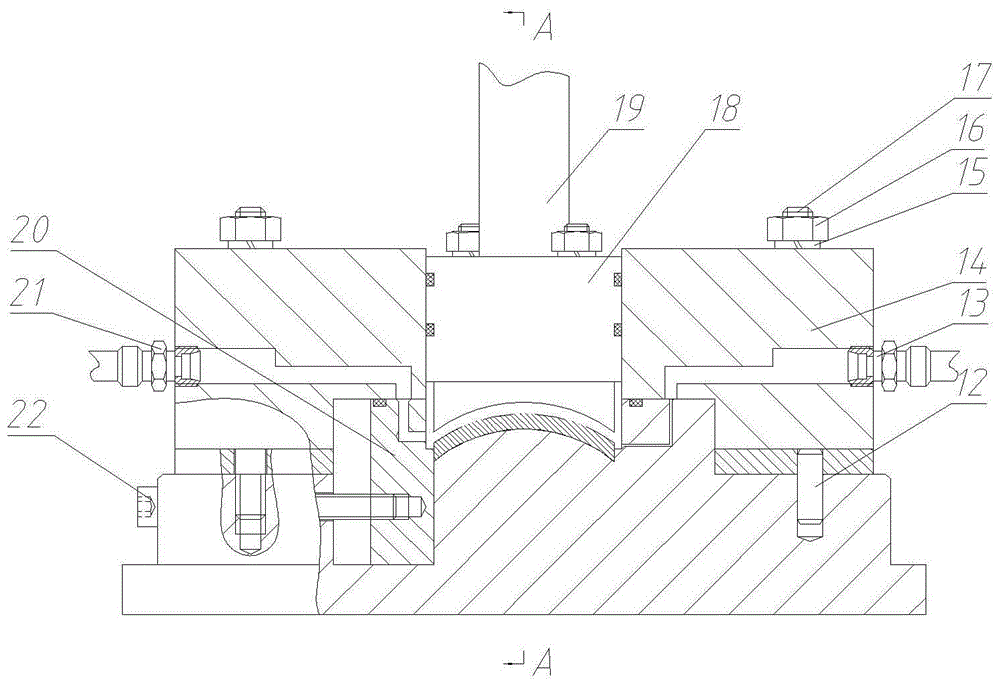

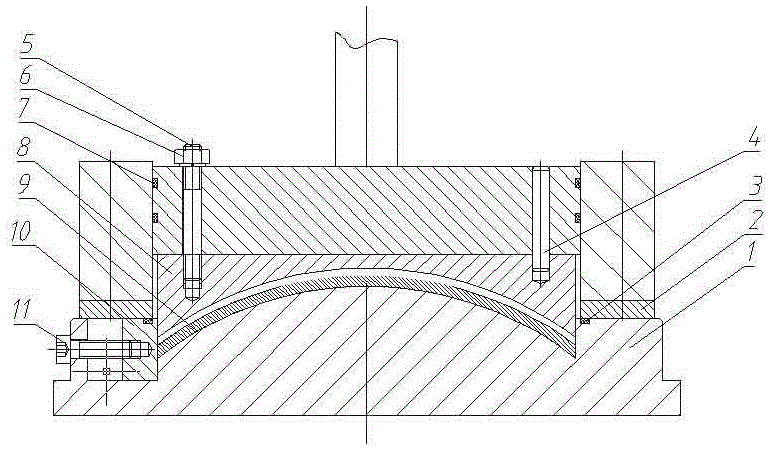

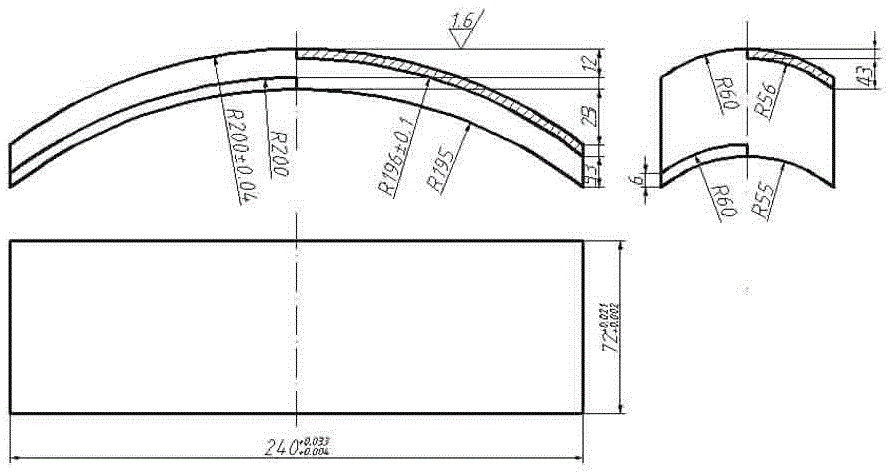

[0024] The invention relates to an electrolytic processing device for special-shaped thin-walled curved surface parts, which includes a fixture base 1, the top surface of the fixture base 1 is provided with a processing surface of the processing part, the curved surface and shape are the same as the processing part 9, and a cathode 8 is provided above the processing surface of the processing part , Cathode connecting plate 18 and cathode connecting rod 19. The cathode connecting plate 18 and the cathode 8 are fixed by the cathode connecting plate pin 4 , the cathode connecting plate bolt 5 and the cathode connecting plate nut 6 . A pair of longitudinal jack blocks 10 and a pair of transverse jack blocks 20 for positioning the machined parts 9 are arranged around the machined surface of the top surface of the fixture base 1, and are passed through the longitudinal jack scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com