Connection thread between drilling tool systems of blasthole drill

A technology of roller cone drilling rig and thread, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc. It can solve the problems of inconvenient maintenance for users, difficulty in thread processing, increased maintenance and spare parts costs, etc., and achieves convenient processing, measurement and inspection, and self-locking performance Good, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

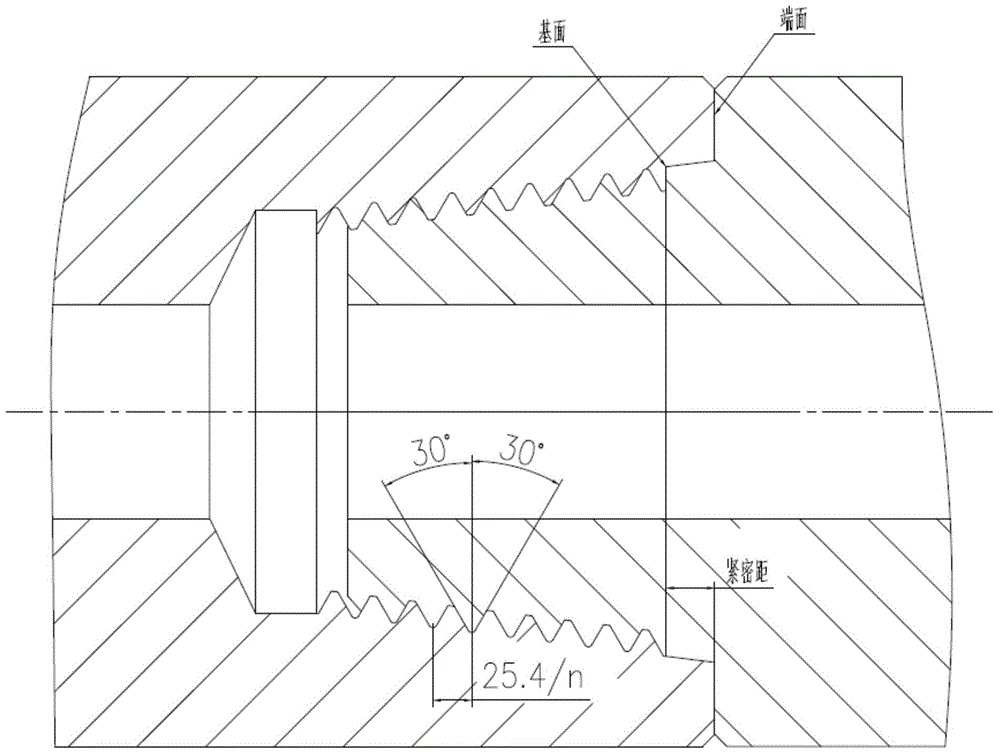

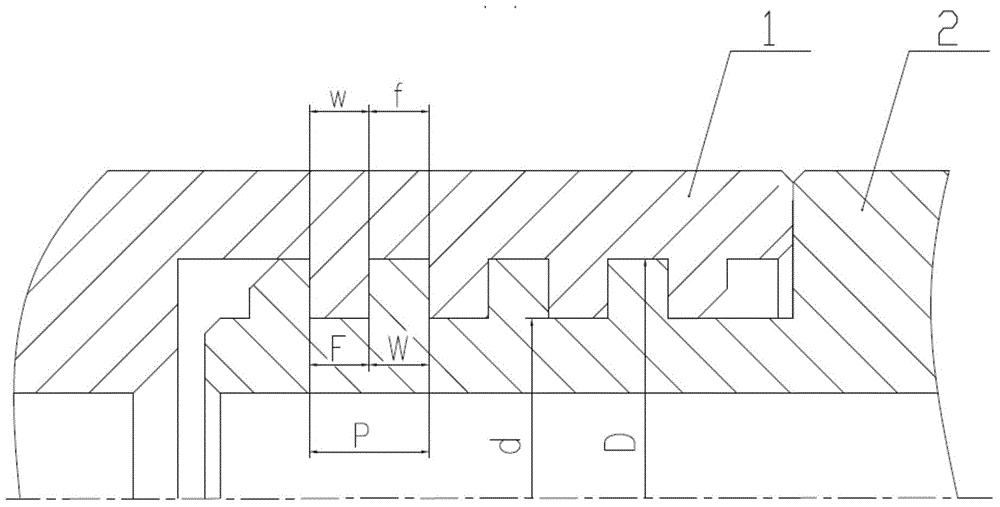

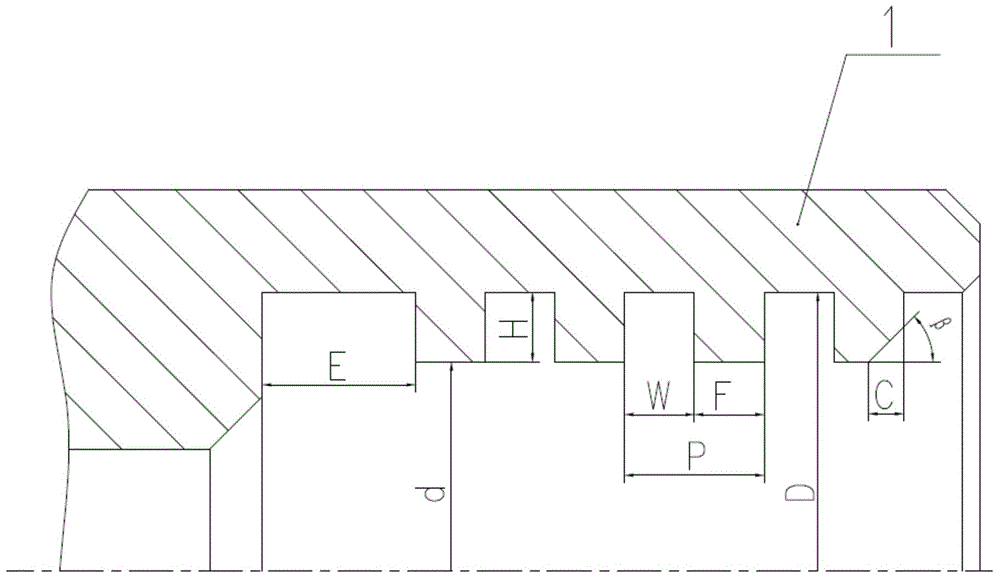

[0016] Such as figure 2 As shown, the cylindrical single-line rectangular thread of the present invention includes a cylindrical single-line rectangular internal thread 1 and a cylindrical single-line rectangular external thread 2. The thread adopts a cylindrical single-line rectangular thread, and the single-line thread has good self-locking performance; The cylindrical body spirals upwards in the axial direction, and the tooth shape of the axial section is a rectangular concave-convex straight tooth; the tooth flank of the thread is a smooth working screwing sliding surface; the thread of the joint has only a major diameter and a minor diameter without a pitch diameter, so The tooth groove W and tooth crest thickness F of the cylindrical single-line rectangular internal thread 1 are respectively screwed with the tooth top thickness f and tooth groove w of the cylindrical single-line rectangular external thread 2, and the rings are tightly locked. buckle and screw it securel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com