Ammonia spraying structure and reactor

A nozzle and straight edge technology, applied in the field of flue gas denitrification, can solve the problems of small effective cross-section and large cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

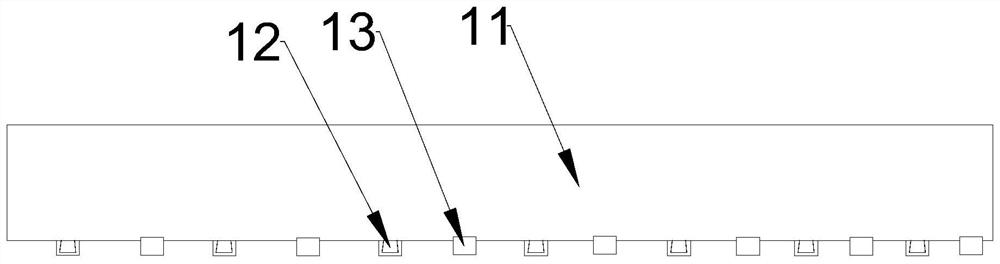

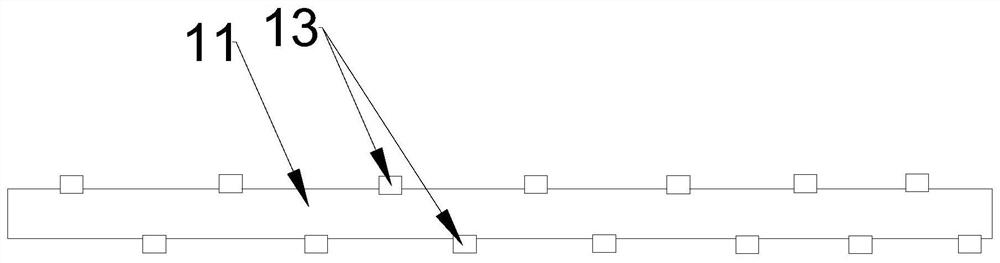

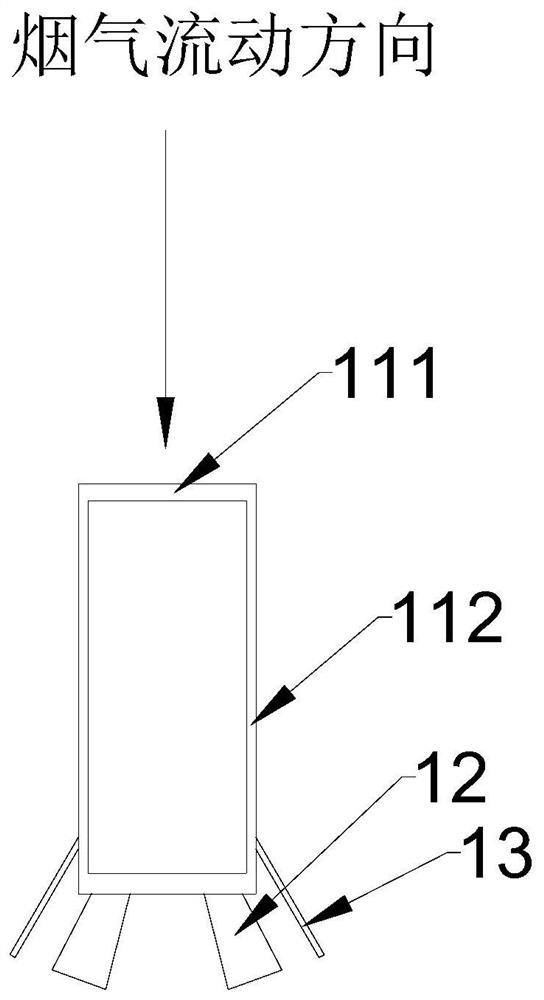

[0034] Such as Figure 1 to Figure 3 As shown, an ammonia injection structure 1 is provided in this embodiment, including an ammonia injection pipe 11, a plurality of nozzles 12 and a plurality of protective plates 13, and the cross section of the ammonia injection pipe 11 includes at least one Straight side 111, and at least one connecting side 112 that is connected with described straight side 111 and encloses a closed space together with described straight side 111; The projection of each described connecting side 112 on described straight side 111 all falls Within the range of the straight side 111, the farthest extension distance of the cross-section in the flue gas flow direction is greater than or equal to the width of the straight side 111; the ammonia injection pipe 11 includes an injection inlet and a plurality of injection outlets; A plurality of nozzles 12 is a tubular structure, one end communicates with the injection outlet, and the other end extends along the di...

Embodiment 2

[0059] In this example, if Figure 4 As shown, a reactor 2 is provided, including an inlet flue 3 and a plurality of the above-mentioned ammonia injection structures 1 , and a plurality of the ammonia injection structures 1 are distributed in the inlet flue 3 . A deflector 4 is arranged inside the inlet flue 3 . Preferably, a plurality of ammonia injection structures 1 are divided into at least two groups along the flue gas flow direction, and each group of ammonia injection structures 1 is evenly distributed on a plane perpendicular to the flue gas flow direction, and two adjacent groups of ammonia injection structures 1 are distributed in the flue gas flow direction. staggered in the direction of flow.

[0060] The ammonia injection structure 1 includes an ammonia injection pipe 11, a plurality of spray nozzles 12 and a plurality of protective plates 13, and the cross section of the ammonia injection pipe 11 includes at least one straight edge 111 perpendicular to the flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com