Full-automatic cleaning machine for vacuum moisture regain turnover box

A fully automatic cleaning and vacuum resurfacing technology, which is applied in the tobacco industry, can solve the problems of the large volume and weight of the vacuum resurfacing turnover box, the inability to clean the tobacco leaves, and the inability to dump them completely, so as to achieve a convenient cleaning cycle and a simple and easy-to-operate working mode , Clean thoroughly and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

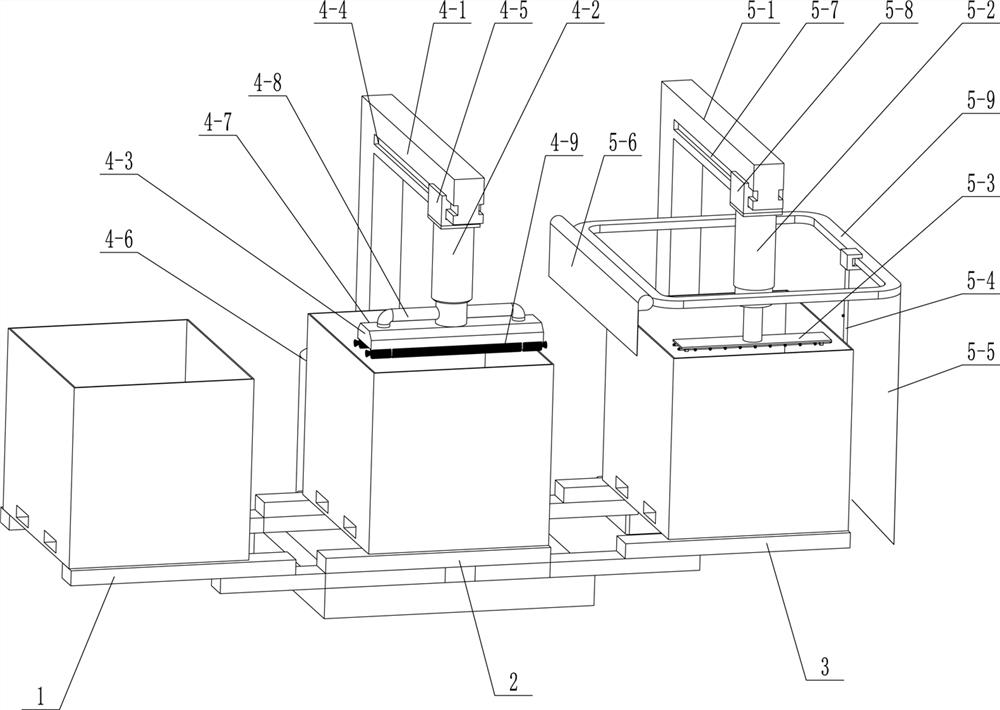

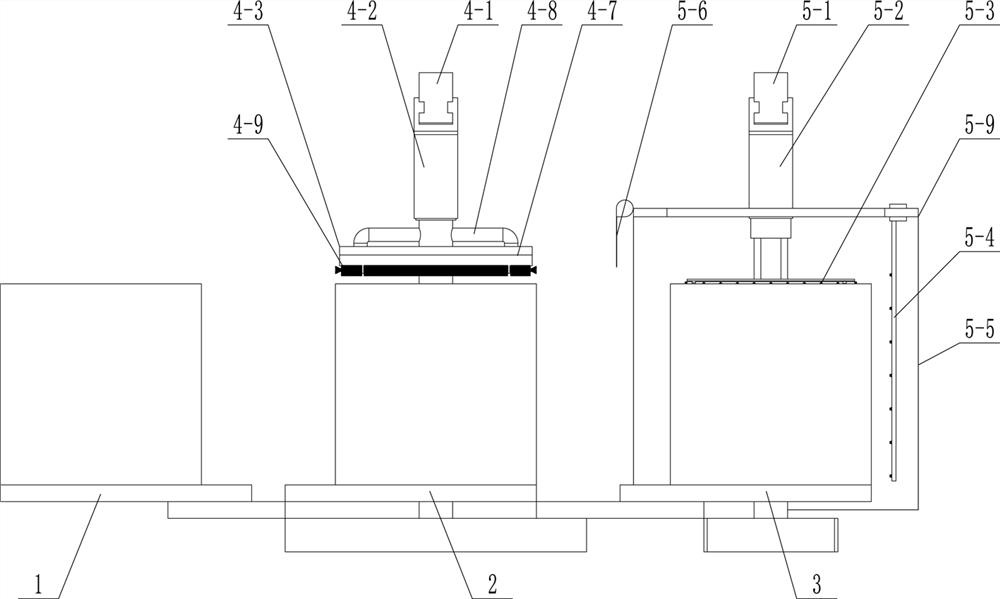

[0024] Such as figure 1 and figure 2 As shown in the figure, a fully automatic cleaning machine for vacuum resurfacing turnover boxes, including a three-station transfer platform, a negative pressure purge collection system and a cleaning system;

[0025] The three-station transfer platform includes a receiving station 1, a cleaning station 2, and a cleaning station 3 arranged in sequence, and the three-station transfer platform is driven by a transverse transfer module to switch positions on the three stations, specifically The traverse motor cooperates with the linear motion component to complete.

[0026] The negative pressure purge system is arranged above the cleaning station, and the negative pressure purge system includes a first forward and backward movement mechanism 4-1, a first up and down movement mechanism 4-2, a cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com