Novel upset head of enhanced precast pile and production method of novel upset head

A prefabricated pile and enhanced technology, applied in sheet pile walls, manufacturing tools, driving devices of forging presses, etc., can solve the problems of low production efficiency and high labor intensity, and achieve improved production efficiency, reduced labor intensity, and reduced personnel labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

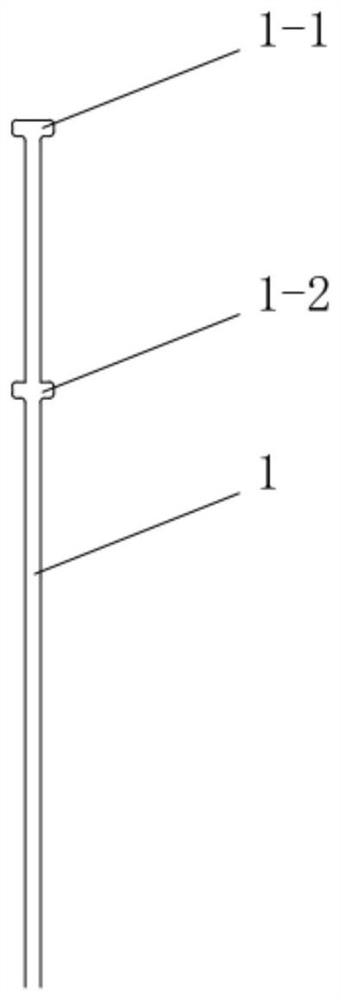

[0073] Such as figure 1 As shown in the above-mentioned a new type of header, the steel bar 1 is provided with an end header 1-1 and a middle header 1-2, and the header is T-shaped. The structure of heading among the present invention also can be conical (as Figure 8 shown). The distance between the end header 1-1 and the middle header 1-2 is 30-100mm. If the distance between two heads is too large, raw materials will be wasted. If the distance is too small, the heads cannot be processed. Therefore, the distance between heads is 30-100mm.

Embodiment 2

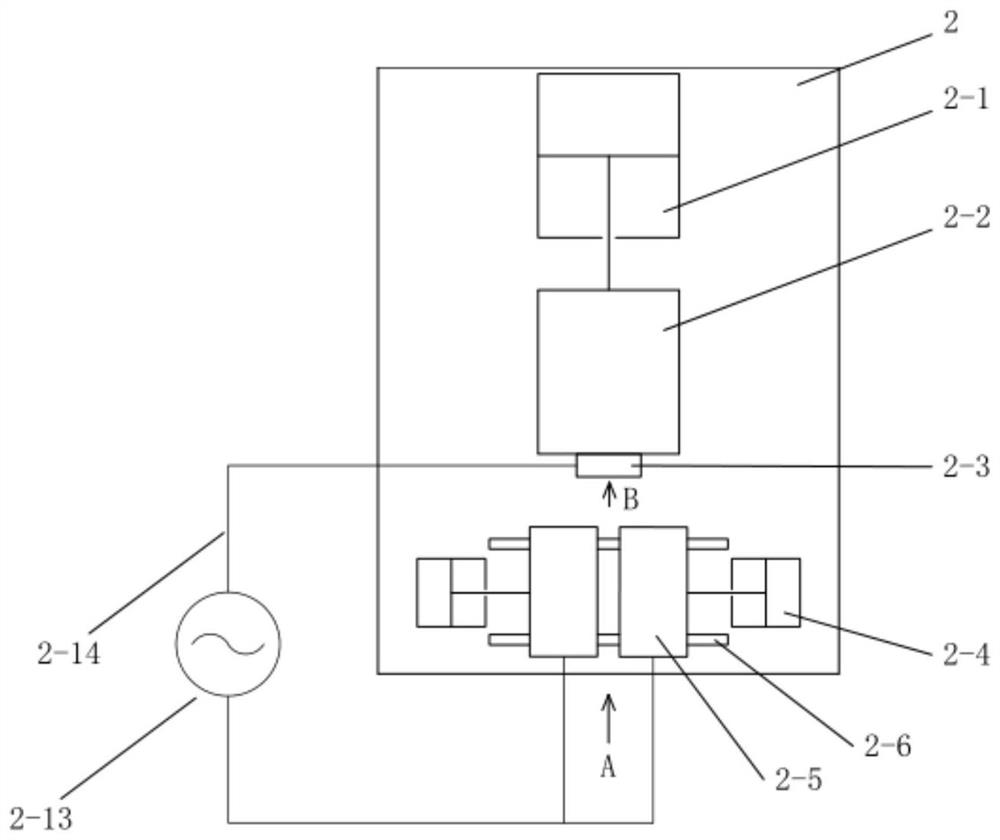

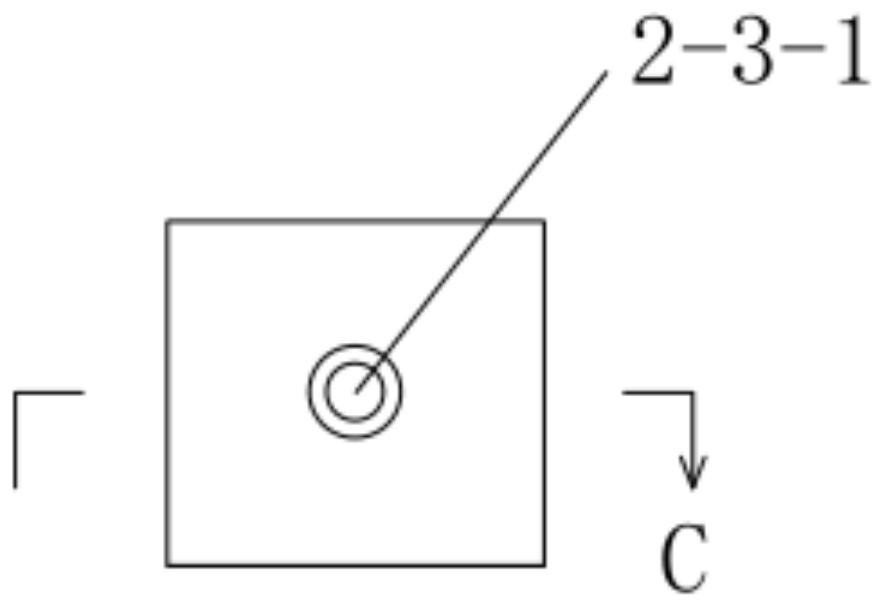

[0075] Such as figure 2 As shown, the heading machine includes an upsetting oil cylinder 2-1, a hammer head cover 2-2, a hammer head 2-3, a clamping oil cylinder 2-4, a clamp 2-5, and a guide rail 2-6. The upsetting oil cylinder 2-1 is fixed on the upsetting machine 2, and the oil cylinder rod of the upsetting oil cylinder 2-1 is connected with the hammer 2-3; the described hammer cover 2-2 is fixed on the upsetting machine 2, The tup 2-3 can slide back and forth in the tup cover 2-2; as image 3 and Figure 4 As shown, the hammer head 2-3 can be a solid structure, and can also be a structure with a hammer head blind hole 2-3-1; as Figure 4 As shown, the blind hole 2-3-1 of the hammer head has a circular platform structure, the diameter of the deepest part of the blind hole 2-3-1 of the hammer head is small, and the diameter of the outlet of the end face of the hammer head 2-3 is relatively large, which is convenient for upsetting in the middle. When the head 1-2 is used,...

Embodiment 3

[0088] 1. After cutting the steel bar 1 to a fixed length, put the steel bar 1 between the symmetrically distributed reverse clamps 2-10 and the symmetrically distributed clamps 2-5, and the head end of the steel bar 1 is against the hammer head 2- 3 up;

[0089] 2. Afterwards, an upsetting instruction is issued, and the clamp 2-5 driven by the clamping cylinder 2-4 moves to the middle, clamps the steel bar 1, and the steel bar 1 is tightly clamped in the clamp groove 2-5-1; and At the same time, the reverse clamp 2-10 driven by the reverse clamp clamping oil cylinder 2-12 moves to the middle to clamp the steel bar 1, and the steel bar 1 is tightly clamped in the groove of the reverse clamp 2-10. The grooves of the fixture 2-10 and the fixture groove 2-5-1 are arranged in the same front and back and have the same structure;

[0090] 3. The power supply 2-13 connects the hammer head 2-3 to the reverse clamp 2-10 through the wire 2-14. When the steel bar 1 contacts the hammer h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com