Welding-free steel pipe connecting process

A welding-free, steel pipe technology, applied in non-removable pipe connections, pipes/pipe joints/fittings, manufacturing tools, etc., can solve problems such as low efficiency, cumbersome operation, affecting laying efficiency, etc., to achieve high connection efficiency and ensure sealing effect, the effect of enhancing the extrusion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

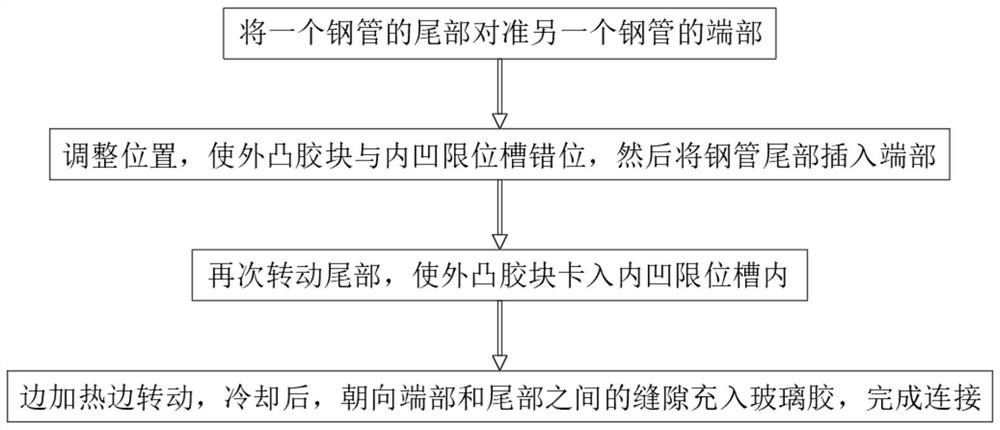

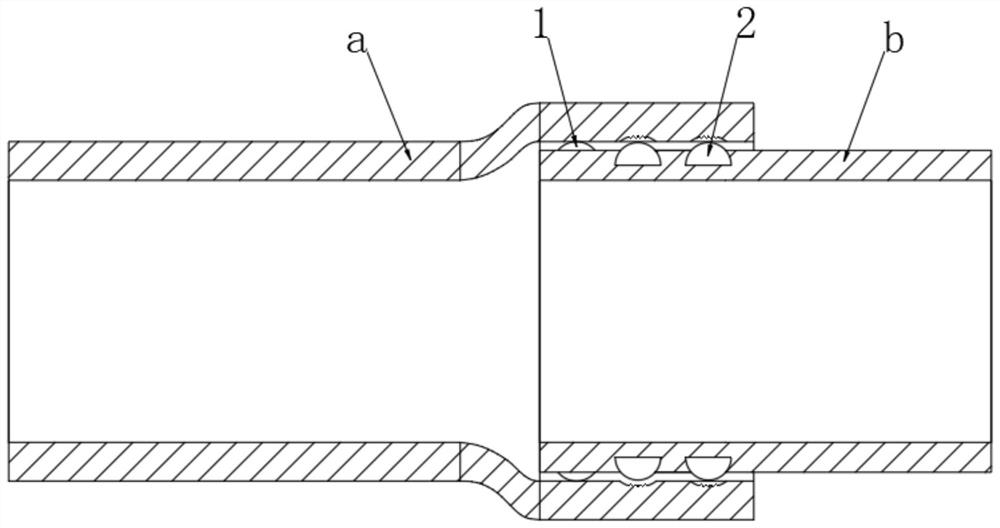

[0047] see figure 1 , in the figure a represents the end of the steel pipe, b represents the tail of the steel pipe, the inner diameter of the end of the steel pipe is slightly larger than the outer diameter of the tail of the steel pipe, a welding-free steel pipe connection process, including the following steps:

[0048] S1. First, align the tail of one steel pipe with the end of the other steel pipe;

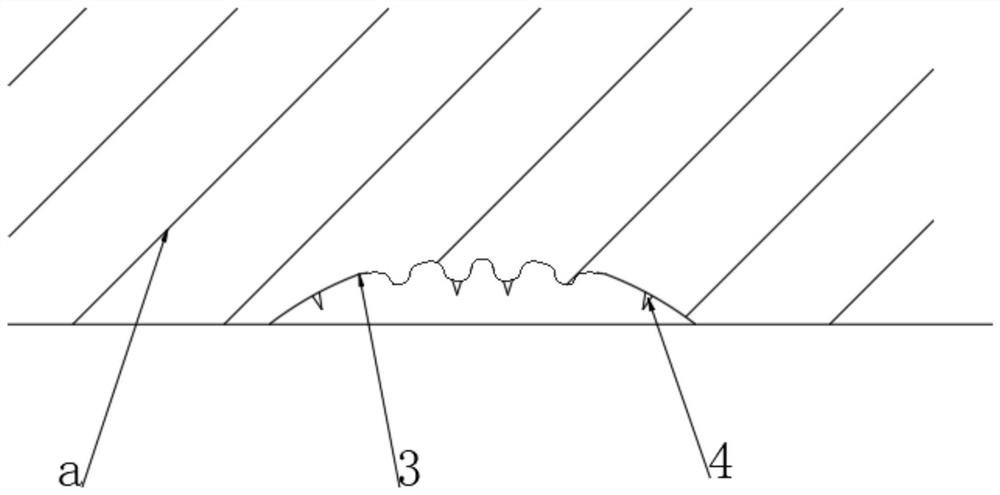

[0049] S2. Twist one of the steel pipes to adjust the position, so that the outer convex rubber block 2 at the tail is misaligned with the inner concave limit groove 3 at the end, and then insert the tail into the end until it stops when it cannot be inserted;

[0050] S3. Rotate the tail again to make the outer convex rubber block snap into the inner concave limit groove;

[0051] S4. Heat the outer wall of the end, rotate while heating, end the heating after 2-3 minutes, and after cooling down, fill the glass glue toward the gap between the end and the tail to complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com