Automatic feeding and discharging single-truss mechanical hand of slicing machine

A technology of automatic loading and unloading and manipulators, which is applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of long transverse distance of manipulators, large space occupation, damage to workpieces, etc., to shorten the transverse length of Y-axis, ensure efficiency and The effect of output and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

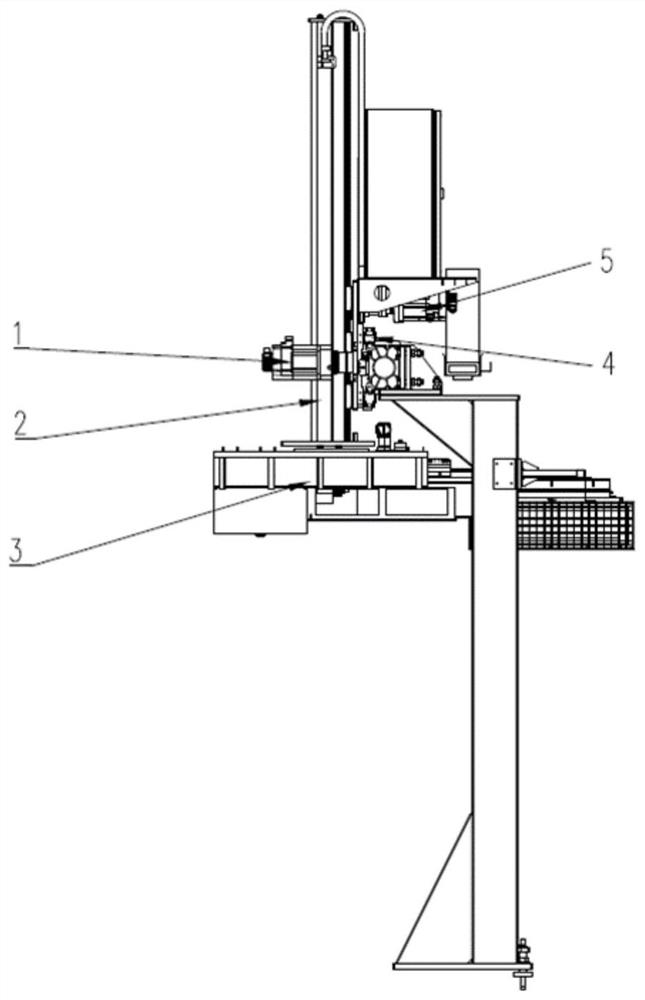

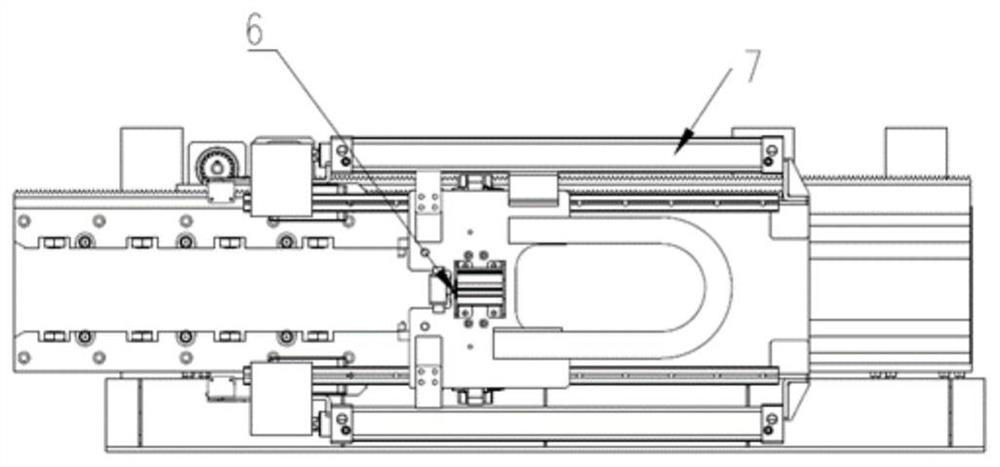

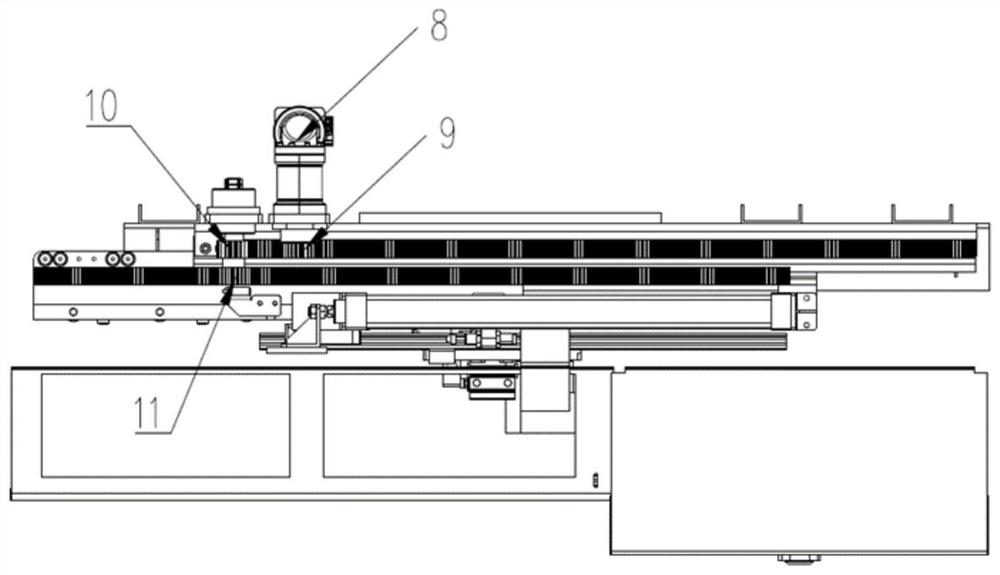

[0020] A single truss manipulator for automatic loading and unloading of slicers, such as Figure 1-3 As shown, it includes truss, X-axis 4, Z-axis 2, Y-axis 3, and manipulator; the X-axis 4, Z-axis 2, and Y-axis 3 are set on the truss, and the X-axis 4 is provided with an X-axis guiding mechanism , the Z-axis 2 is provided with a Z-axis guide mechanism, the Y-axis 3 is provided with a Y-axis guide mechanism, and the X-axis 4 is connected with the manipulator through the X-axis guide mechanism; the Y-axis 3 is also provided with There is a Y-axis slide plate, the two sides of the Y-axis slide plate are connected with the Y-axis guide mechanism, the Y-axis slide plate is also provided with a jaw cylinder 6, and the X-axis 4, Z-axis 2, and Y-axis 3 are respectively equipped with There are X-axis motor 1, Z-axis motor 5, and Y-axis motor 8;

[0021] The X-axis guide mechanism includes a guide profile, a steel shaft, and an arc shaft; the upper and lower sides of the arc shaft ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com