Intelligent stacking machine for concrete test pieces

A technology for concrete specimens and stackers, which is applied to conveyors, object destacking, conveyor objects, etc., can solve the problem of high labor intensity in stacking work, and achieve the release of manual transfer workload, accurate in place, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

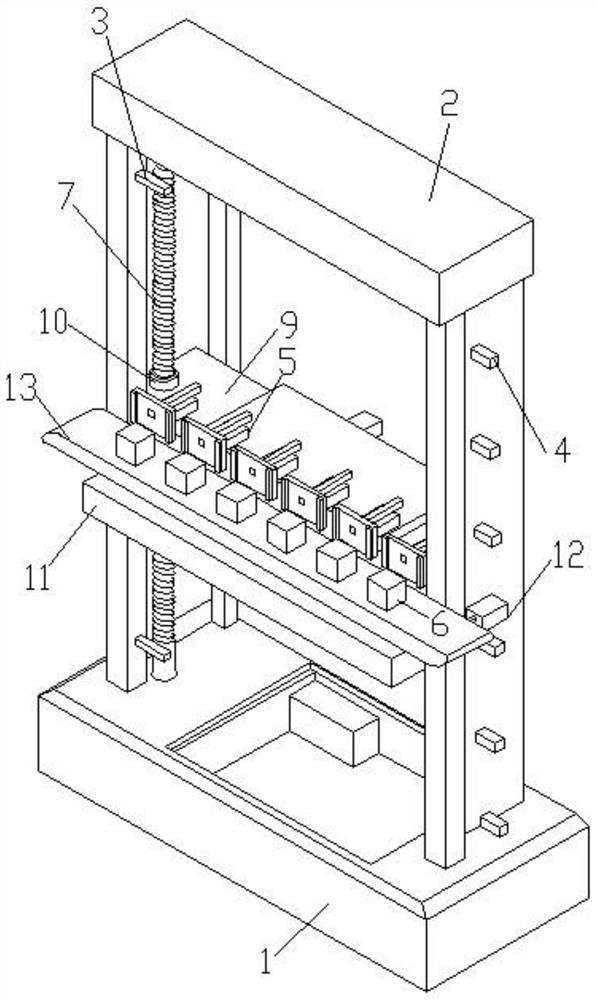

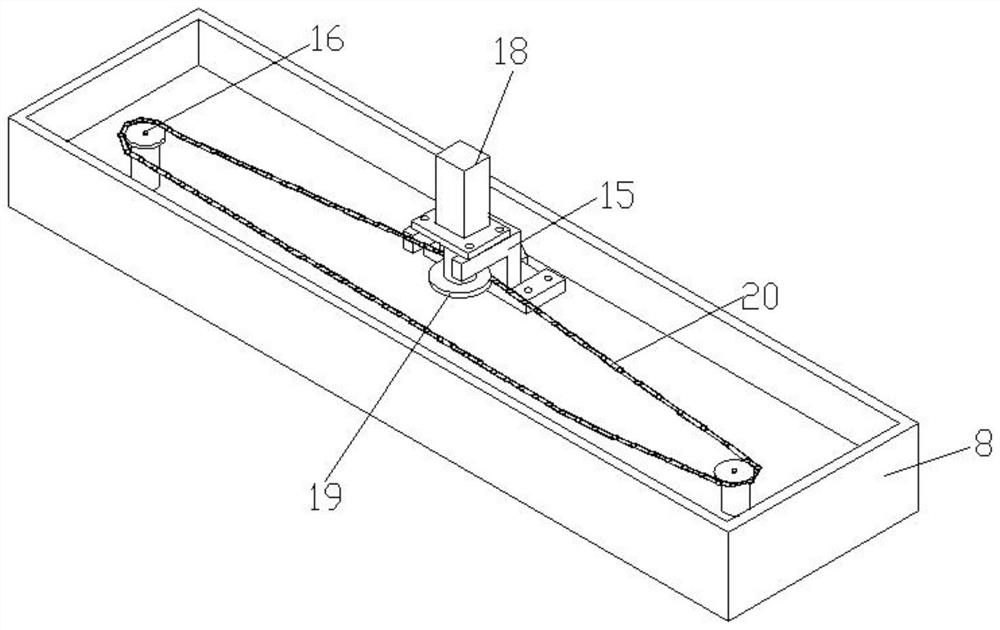

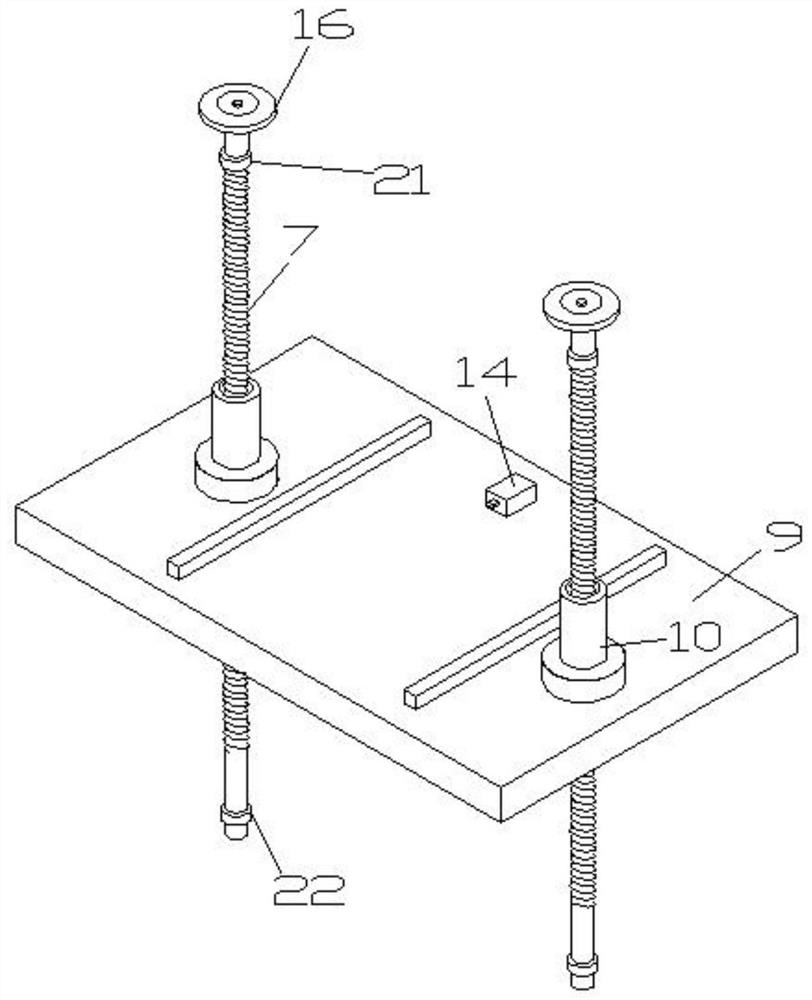

[0032] as attached figure 1 As shown: the intelligent stacking machine for concrete specimens, including a base 1 and a support frame 2 welded on the base 1, the upper and lower ends of the front side of the support frame 2 are provided with mechanical limit switches 3, and each mechanical limit switch 3 is Located on the motion track of the lifting platform 9. The right side of the support frame 2 is equidistantly distributed with a plurality of electronic limit switches 4 for limiting the movement of the lifting platform 9. The electronic limit switch 4 is arranged between two mechanical limit switches 3, and the mechanical limit switch 3 is connected to the electronic limit switch 4. The limit switches 4 are all connected with the transmission motor 18 signal. The support frame 2 is symmetrically provided with grooves, and each groove is rotatably connected with a longitudinally arranged screw 7, and the top of each screw 7 is provided with a roller bearing 21, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com