A kind of early-strength soil stabilizer and its preparation method and application

A soil curing agent and soil technology, applied in the direction of chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problems of complex steps in the construction process, long construction period, low early strength, etc., to improve the bonding strength and water resistance Sexuality, low cost, high early strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The present embodiment provides a kind of early-strength soil curing agent, and its specific preparation method is:

[0061] 1), the preparation of toluene diisocyanate modified polyvinyl alcohol emulsion:

[0062] In a 500ml three-necked flask, add 250ml of water, heat to 100°C, accurately weigh 30g of polyvinyl alcohol particles, pour it into the three-necked flask, continue stirring at 150rpm until completely dissolved; continue to add emulsifier Tween-80, 0.5g, Stir and lower the temperature to 40°C; continue to drop 2.5 g of toluene diisocyanate in the emulsion, increase the rotation speed to 500 rpm, and continue the reaction for 2 hours, which is the desired isocyanate-modified polyvinyl alcohol emulsion.

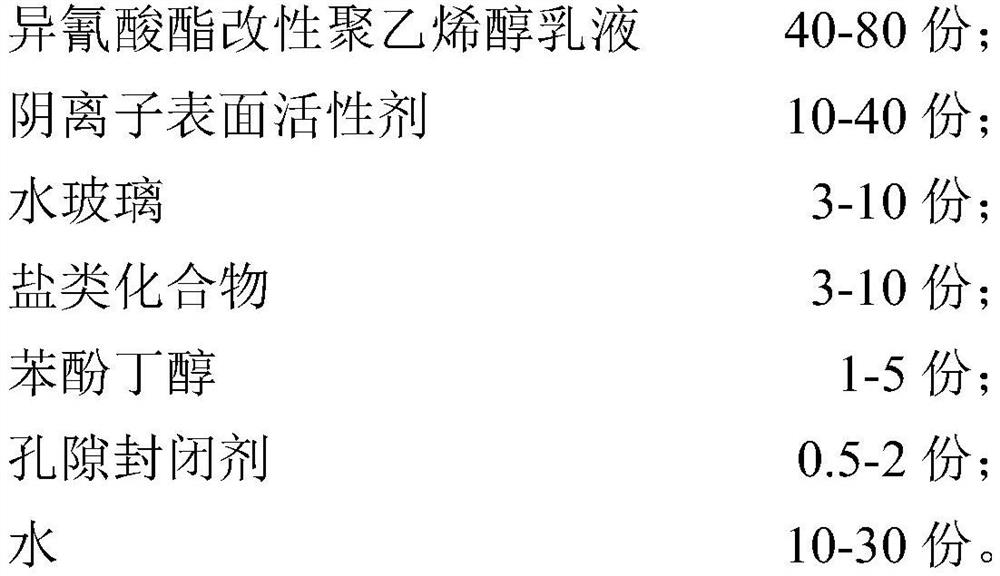

[0063] 2), the preparation of early-strength soil curing agent (the following parts are parts by weight):

[0064] In a 250ml beaker, add 10 parts of water, heat to 40°C, add 3 parts of sodium sulfate, 1 part of sodium chloride, and 6 parts of water glass at ...

Embodiment 2

[0066] The present embodiment provides a kind of early-strength soil curing agent, and its specific preparation method is:

[0067] 1), the preparation of toluene diisocyanate modified polyvinyl alcohol emulsion:

[0068] In a 500ml three-necked flask, add 250ml of water, heat to 100°C, accurately weigh 30g of polyvinyl alcohol particles, pour it into the three-necked flask, continue stirring at 150rpm until completely dissolved; continue to add emulsifier Tween-80, 0.5g, Stir and lower the temperature to 40°C; continue to drop 1 g of toluene diisocyanate in the emulsion, increase the rotation speed to 500 rpm, and continue to react for 2 hours, which is the desired isocyanate-modified polyvinyl alcohol emulsion.

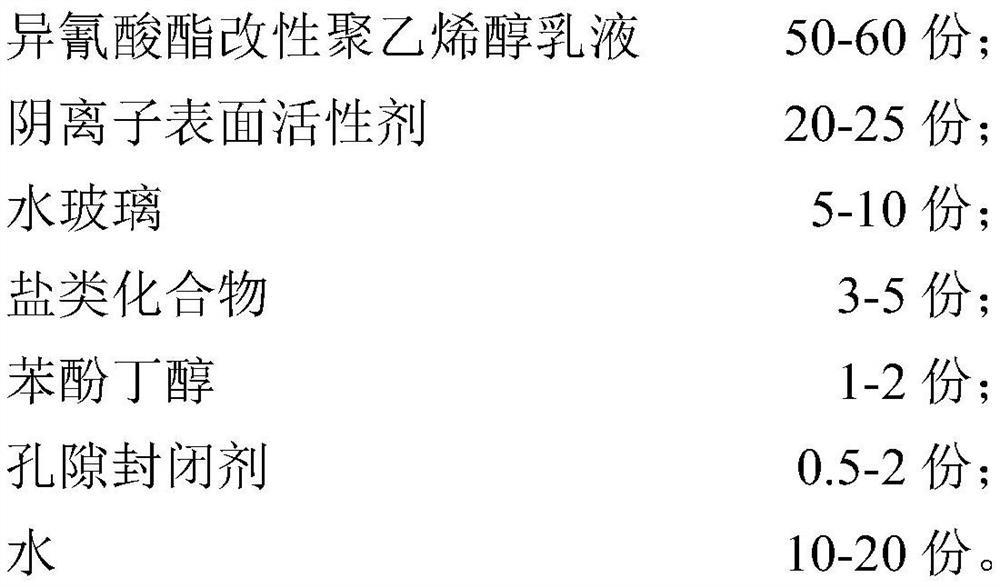

[0069] 2), the preparation of early-strength soil curing agent (the following parts are parts by weight):

[0070] In a 250ml beaker, add 10 parts of water, heat to 40°C, add 3 parts of sodium sulfate, 1 part of sodium chloride, and 6 parts of water glass at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com