Fermented compost stirring and raking device in sludge treatment tower

A technology for sludge treatment and stirring harrow, which is applied in the direction of biological organic part treatment, organic fertilizer, fertilization device, etc., can solve the problems such as rapid volatilization of water unfavorable for fermentation compost, inability to plough, gentle stirring, and low production efficiency, etc. Time saving, evaporation reduction, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

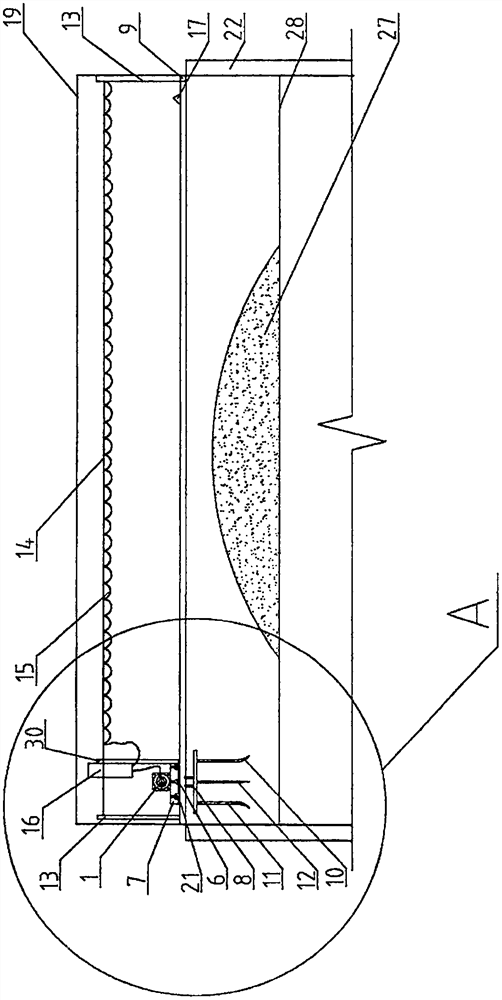

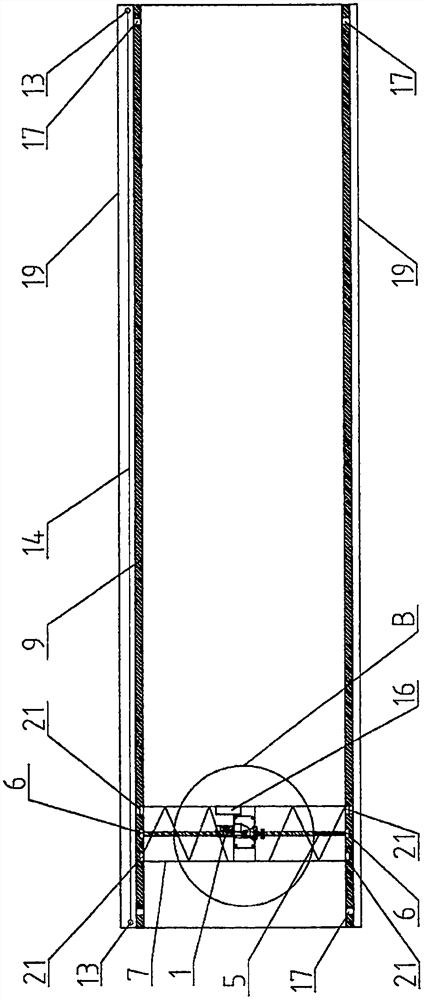

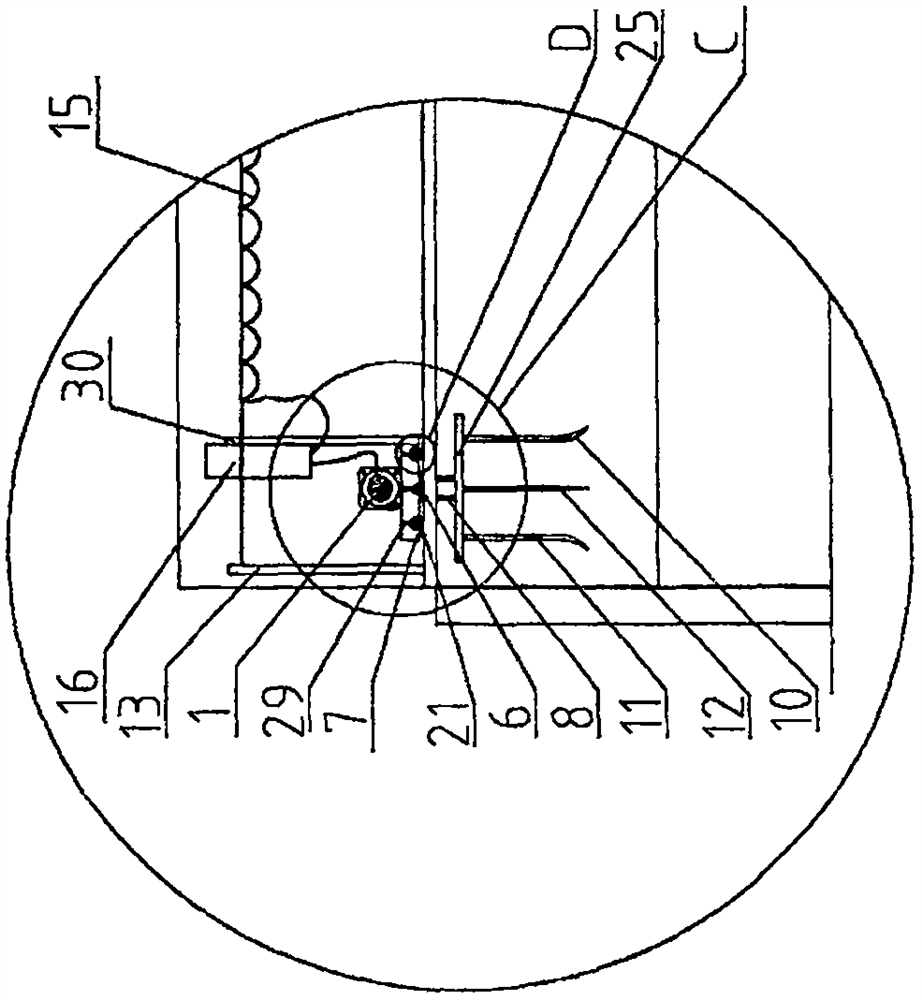

[0027] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11: it is mainly composed of drive device (1), gear A (2), chain (3), gear B (4), connecting shaft ( 5), driving roller (6), truss (7), frame column (8), track (9), forward rake (10), reverse rake (11), crushing rake (12), cable bracket (13), steel wire rope (14), cable (15), electric control cabinet (16), limit switch (17), bearing (18), protective cover channel steel (19), protective cover (20), passive roller ( 21), fermentation tower wall (22), tower body aisle plate (23), roller block (24), rack (25), transfer switch (26), material (27), silo floor (28), Composed of roller brackets (29) and electric control brackets (30), the truss (7) of the fermented compost stirring and leveling device is placed in the upper part of the sludge treatment tower, and the driving device (1) is placed in the middle and upper part of the truss (7) , the electric control bracket (30) of the electric control cabinet (16) is fixed above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com