An orange coupling type disperse dye compound and its dyeing process

A technology of disperse dyes and complexes, applied in the field of organic dyes, can solve the problems of low dye uptake, difficulty in diffusion, and deepening of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

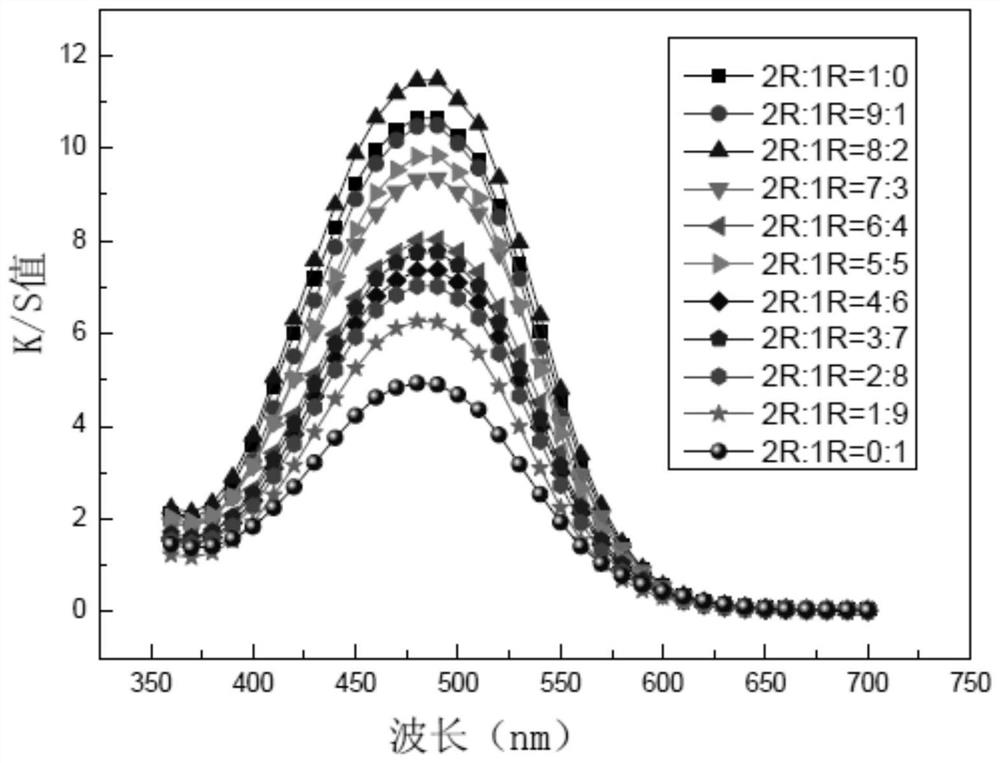

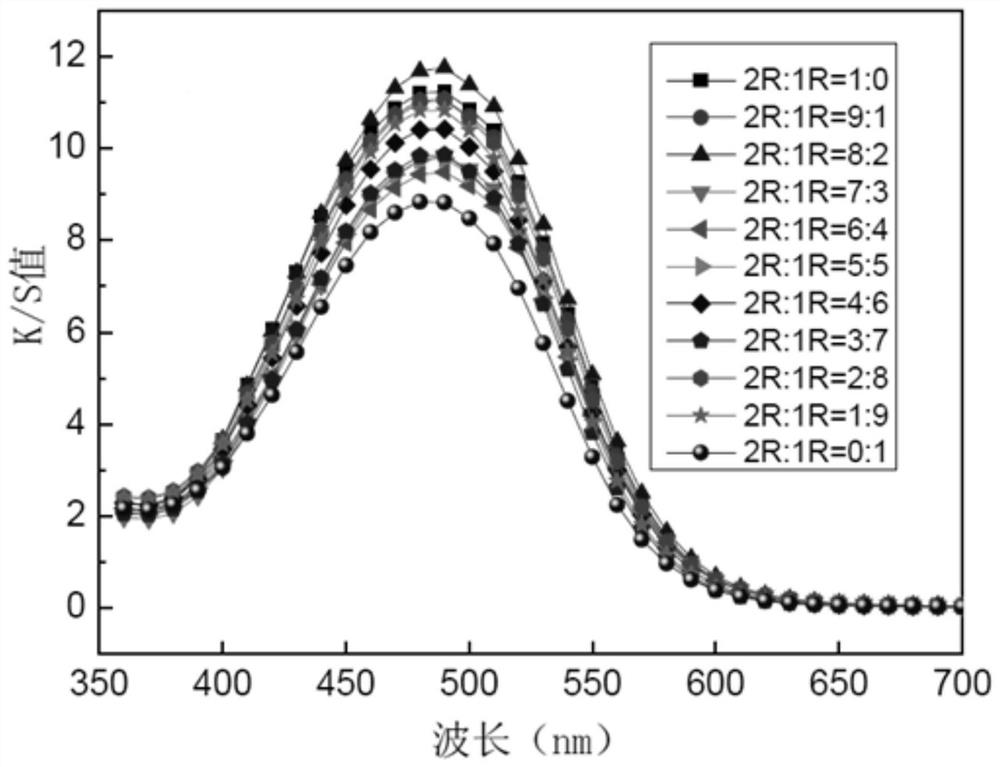

[0030] Example 1: The effect of compounding in different proportions on dyeing

[0031] Two orange conjugated disperse dyes are used in combination, changing different mass ratios, to dye suede fabrics, the total concentration of dyes is 2% (o.w.f), the quality of dyeing auxiliaries (super dispersant Solsperse20000 and penetrant AEP) The ratio is 4:6) the concentration is 1g / L, the ammonium sulfate is 1g / L, and the bath ratio is 30:1.

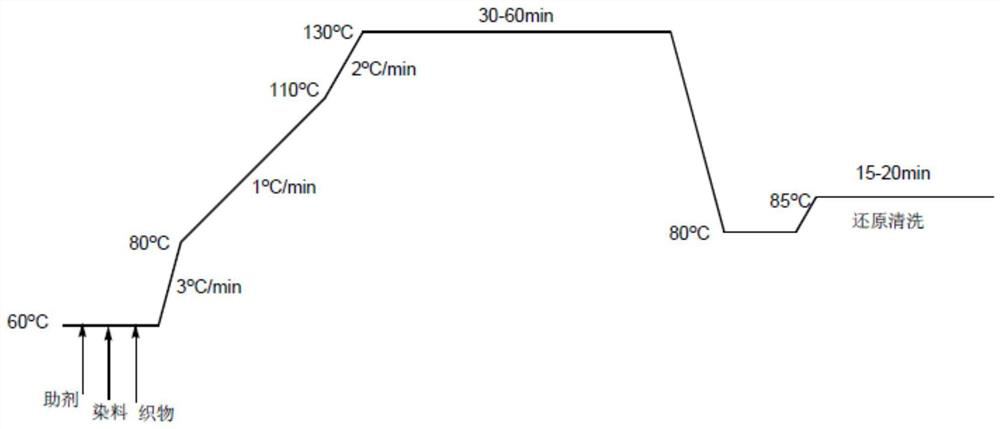

[0032] After the dye solution is prepared, see figure 1 The dyeing process curve shown is dyed: dyeing at 60 °C, first heating to 80 °C at a rate of 3 °C / min, adjusting to 1 °C / min and heating to 110 °C, and then heating to 130 °C at 2 °C / min, respectively. Incubate for 30min and 60min, cool down to 80°C for drainage, and then inject water to raise the temperature to 85°C for reduction cleaning for 15min. After washing twice, drain the cloth and dry it.

[0033] The apparent color depth values at different wavelengths were measured when the...

Embodiment 2

[0044] Example 2: Influence of different dyeing processes on dyeing effect

[0045] The above-mentioned optimal compound (the mass ratio of disperse orange HF-2R: disperse orange HF-R to 8:2) is used as the dye for dyeing, and experiments are carried out on the confirmation process of each parameter of the dyeing process, as follows:

[0046] When the compound concentration of dye is 2% (o.w.f), the concentration of dispersant MF is changed, ranging from 0-2.5g / L, and the concentration of auxiliaries (mass ratio of super dispersant Solsperse20000 and penetrant AEP is 4:6) is 1g / L, ammonium sulfate 1g / L, the bath ratio is 30:1, the dyeing temperature rise control is the same as that of Example 1, and the temperature is kept for 60min. After dyeing, determine the apparent color depth value of the dyed sample at the maximum absorption wavelength, and see the obtained results. Figure 4 shown.

[0047] from Figure 4 It can be seen that when the dispersant MF dosage is 0-2g / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com