Dyeing method of cellulose fiber material

A technology of cellulose fiber and cellulase, which is applied in the textile field, can solve the problems of light color, low dye utilization rate, and the use of mordants, etc., to improve the color depth of dyeing, good biocompatibility, and improve selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

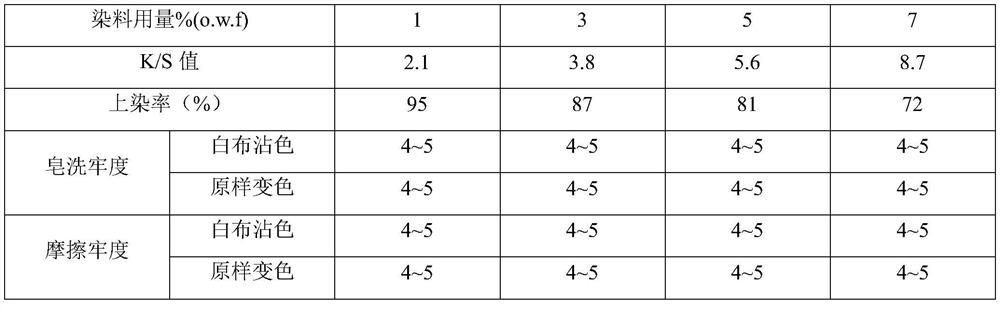

[0052] A method for dyeing cotton fabric on gardenia blue pigment, comprising the steps:

[0053] (1) Preparation of gardenia blue pigment:

[0054] 10g of cellulase (enzyme activity is 500U / g) was added to 50g of gardeniside, enzymatically hydrolyzed at 40°C for 48h, and concentrated under reduced pressure to a solid content of 20% to obtain gardenia aglycone; then phosphate buffered saline was used The gardenia aglycone was prepared into 150 g of a gardenia aglycone solution with a concentration of 5%, and then 5 g of glycine was reacted at 75° C. for 5 hours, separated and purified to obtain a gardenia blue pigment.

[0055] (2) Pretreatment of cotton fabrics:

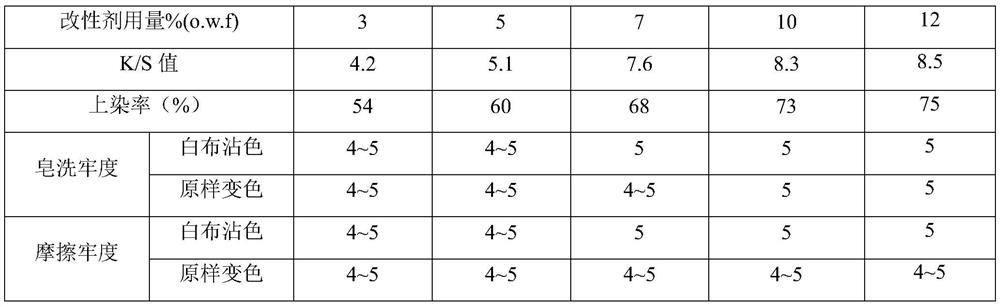

[0056] Mix the polydiene dimethyl ammonium chloride, aminopropyltrimethoxysilane modifier, sodium hydroxide and water to obtain a modifier solution; then immerse the cotton fabric in the modifier solution, at 80°C Modified for 30min, taken out to obtain pretreated cotton fabric; wherein, the mass ratio of polydien...

Embodiment 2

[0065] A method for dyeing cotton fabric on gardenia blue pigment, comprising the steps:

[0066] (1) Preparation of gardenia blue pigment:

[0067] 10g of cellulase (enzymatic activity of 700U / g) was added to 50g of gardeniside, enzymatically hydrolyzed at 40°C for 48h, and concentrated under reduced pressure to a solid content of 20% to obtain gardenia aglycone; then phosphate buffered saline was used The gardenia aglycone was prepared into 200 g of gardenia aglycone solution with a concentration of 5%, and then 8 g of L-threonine was reacted at 75 ° C for 5 hours, separated and purified to obtain gardenia blue pigment;

[0068] (2) Pretreatment of cotton fabrics:

[0069] Mix (3-chloro-2-hydroxypropyl)trimethylammonium chloride modifier, aminopropyltrimethoxysilane modifier, sodium hydroxide and water to obtain a modifier solution; Immerse in modifier solution, modify at 80°C for 30min, and take out to obtain pretreated cotton fabric; wherein, (3-chloro-2-hydroxypropyl)tr...

Embodiment 3

[0078] A method for dyeing lyocell fabric on gardenia blue pigment, comprising the steps of:

[0079] (1) Preparation of gardenia blue pigment:

[0080] 10g of cellulase (enzymatic activity of 400U / g) was added to 50g of geniposide, enzymatically hydrolyzed at 40°C for 48h, and concentrated under reduced pressure to a solid content of 20% to obtain geniposide; then phosphate buffered saline was used The gardenia aglycone was prepared into 300 g of gardenia aglycone solution with a concentration of 5%, and then 12 g of L-threonine was reacted at 75°C for 5 hours, separated and purified to obtain gardenia blue pigment;

[0081] (2) Pretreatment of lyocell fabric:

[0082] Mix trimethyl[3-(triethoxysilyl)propyl]ammonium chloride, 3-aminopropyltriethoxysilane modifier, sodium hydroxide and water to obtain a modifier solution; then The lyocell fabric was dipped in the modifier solution, modified at 80°C for 30 min, and taken out to obtain the pretreated lyocell fabric; wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com