Method for promoting fixation and dyeing of cotton fabric

A technology of cotton fabric and dyeing accelerator, applied in the field of cotton fabric dyeing and finishing, can solve the problems of poor color fixation effect and large salt consumption, achieve better dyeing effect, reduce salt consumption, and increase color depth value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

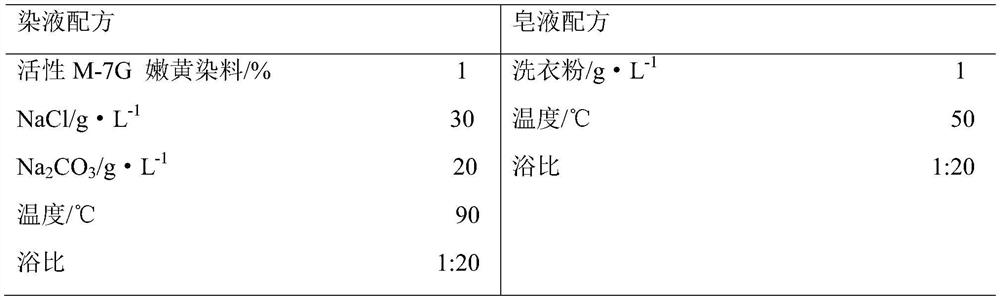

[0019] After scouring and bleaching, the cotton fabric is soaked in reactive M-7G bright yellow dye and NaCl dyeing accelerator. The dyeing time is 30 minutes, and then taken out and added with NaCl 2 CO 3 , Fixing time is 25min. The entire dyeing and color fixing process is in an electron beam radiation environment, and the radiation dose is selected as 30kGy. Wash with water at room temperature for 3 minutes, at 50°C for 3 minutes, at 90°C with washing powder soap for 10 minutes, then at 50°C for 3 minutes, then wash and dry at room temperature.

[0020] Table 1 dye solution and soap solution formula

[0021]

Embodiment 2

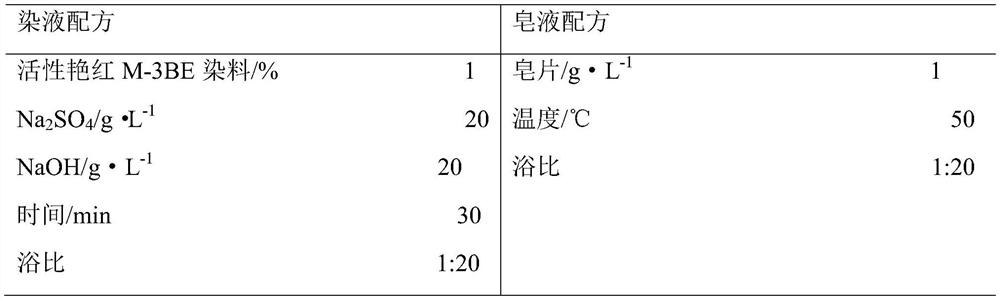

[0023] Cotton fabric soaked in reactive brilliant red M-3BE dye and Na 2 SO 4 In the dyeing accelerator, the dyeing time is 30 minutes, then take out and add NaOH, and the color fixing time is 25 minutes. The entire dyeing and color fixing process is in an electron beam radiation environment, and the radiation dose is selected as 40kGy. Wash with water at room temperature for 3 minutes, at 50°C for 3 minutes, at 90°C with soap flakes for 10 minutes, then at 50°C for 3 minutes, then at room temperature and dry.

[0024] Table 2 dye solution and soap solution formula

[0025]

Embodiment 3

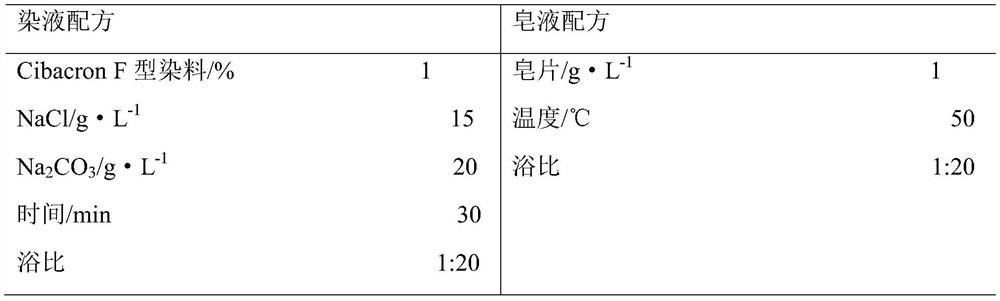

[0027] After scouring and bleaching, the cotton fabric is soaked in reactive Cibacron F dye and NaCl dyeing accelerator for 30 minutes, and then taken out and added with NaCl 2 CO 3 , Fixing time is 20min. The entire dyeing and color fixing process is in an electron beam radiation environment, and the radiation dose is selected as 50kGy. Wash with water at room temperature for 3 minutes, at 50°C for 3 minutes, at 90°C with soap flakes for 10 minutes, then at 50°C for 3 minutes, then at room temperature and dry.

[0028] Table 3 dye solution and soap solution formula

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com