Intelligent well completion system and method based on optical fiber monitoring and layered flow control

A stratified flow, intelligent completion technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problem that the real-time online measurement of downhole temperature and pressure in oil and gas fields cannot be realized, and the measurement data cannot reflect real parameters, which affects the oil field. Production efficiency and other issues, to achieve the effect of reducing measurement costs, occupying small space and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

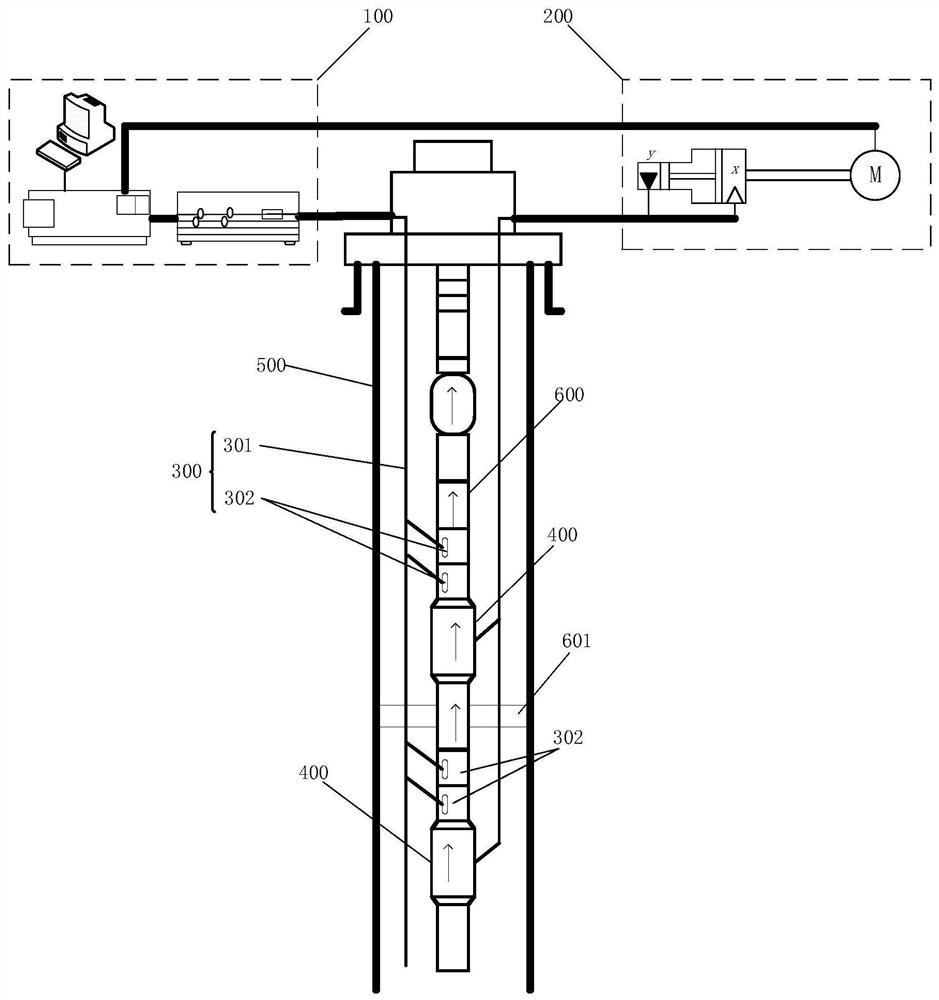

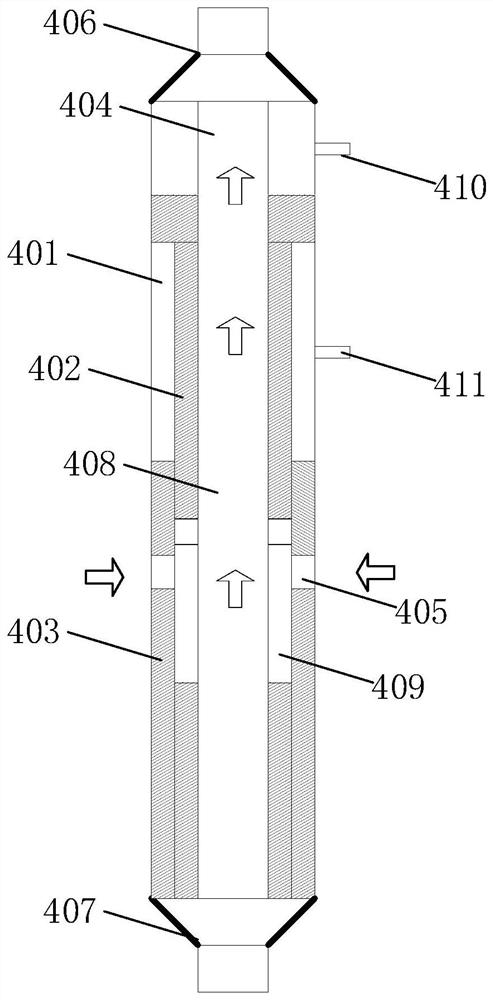

[0055] See figure 1 , the first aspect of the embodiment of the present invention provides an intelligent well completion system based on optical fiber monitoring and layered flow control, including: a surface signal processing subsystem 100, a surface hydraulic subsystem 200, a downhole dynamic monitoring subsystem 300 and a plurality of flow control device 400. The downhole dynamic monitoring subsystem 300 includes a sensing optical fiber 301 and a plurality of optical fiber sensor assemblies 302 . The sensing optical fiber 301 is installed in the oil well casing 500 and extends along the oil well. The sensing optical fiber 301 is located on one side of the oil pipe 600 . The upper end of the sensing optical fiber 301 is connected to the surface signal processing subsystem 100 . In this embodiment, the sensing optical fiber 301 runs through all production layers downhole, and a packer 601 is arranged between two adjacent production layers, and the sensing optical fiber 301 ...

Embodiment 2

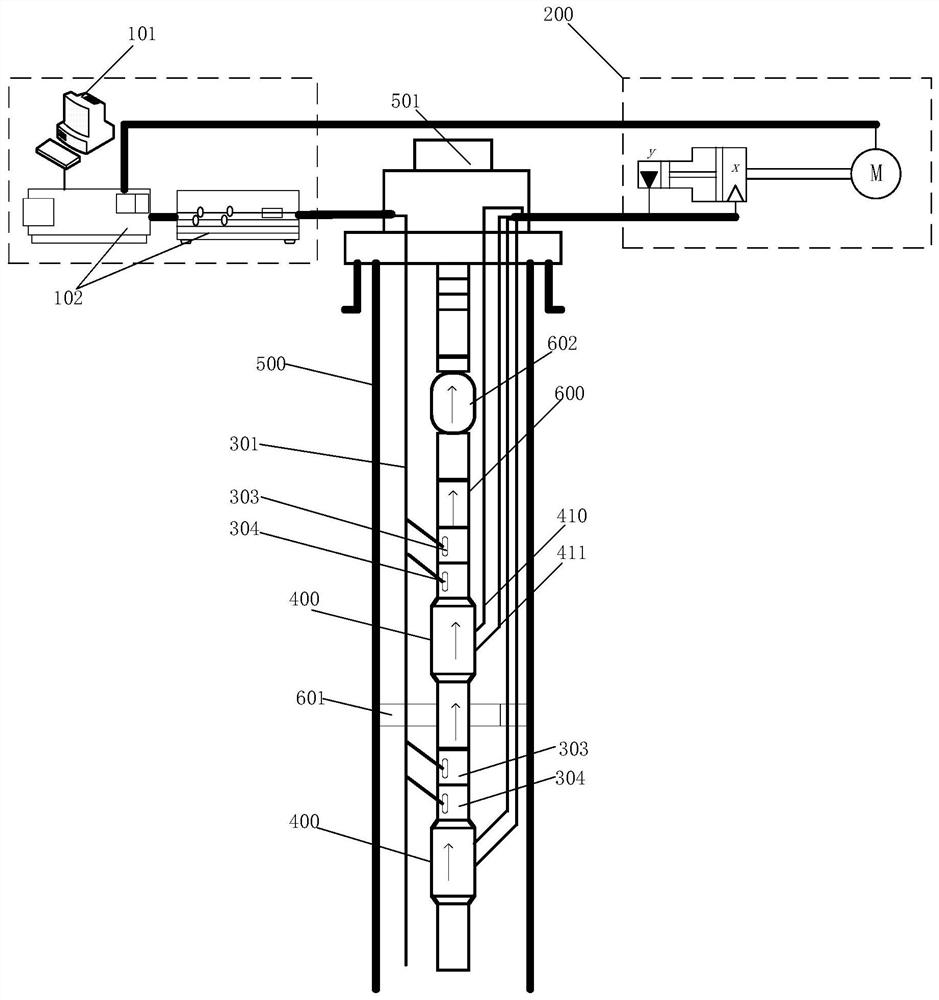

[0063] Such as figure 2 As shown, this embodiment is based on the first embodiment, and further defines that the sensing optical fiber 301 passes through the wellhead Christmas tree 501 and is fixed on one side of the tubing 600 . In this embodiment, the oil well pump 602 is arranged on the oil pipe 600 , and the sensing optical fiber 301 is located on one side of the oil pipe 600 and the oil well pump 602 . Further, the sensing optical fiber 301 can also detect and monitor the working state of the oil well pump 602 . Specifically, the sensing optical fiber 301 can sense vibration and sound waves generated by the oil well pump 602 during operation.

[0064] Further, as figure 2 As shown, the ground signal processing subsystem 100 includes: a server 101 and a signal processor 102 . The server 101 is electrically connected to the signal processor 102 . The signal processor 102 is connected to the sensing optical fiber 301, and the signal processor 102 is electrically conne...

Embodiment 3

[0074] Such as Figure 2-Figure 4 As shown, the second aspect of the embodiment of the present invention provides an intelligent well completion method based on optical fiber monitoring and layered flow control, which is applied to the monitoring system of the first embodiment above, including the following steps:

[0075] Step 1, the ground signal processing subsystem 100 generates an excitation light source for the sensing fiber 301 .

[0076] Step 2: After receiving the excitation light source, the optical fiber sensor assembly 302 detects the state of the production layer and returns the first optical signal to the ground signal processing subsystem 100, and the sensing optical fiber 301 returns the second optical signal. In this step, the state of the production layer includes temperature, pressure and flow. The sensing fiber 301 uses the incident laser pulse to excite the corresponding backscattering spectrum signals in the sensing fiber 301, that is, Rayleigh, Brilloui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com