Optimization model for realizing collaborative production of oil and gas wells on offshore platform

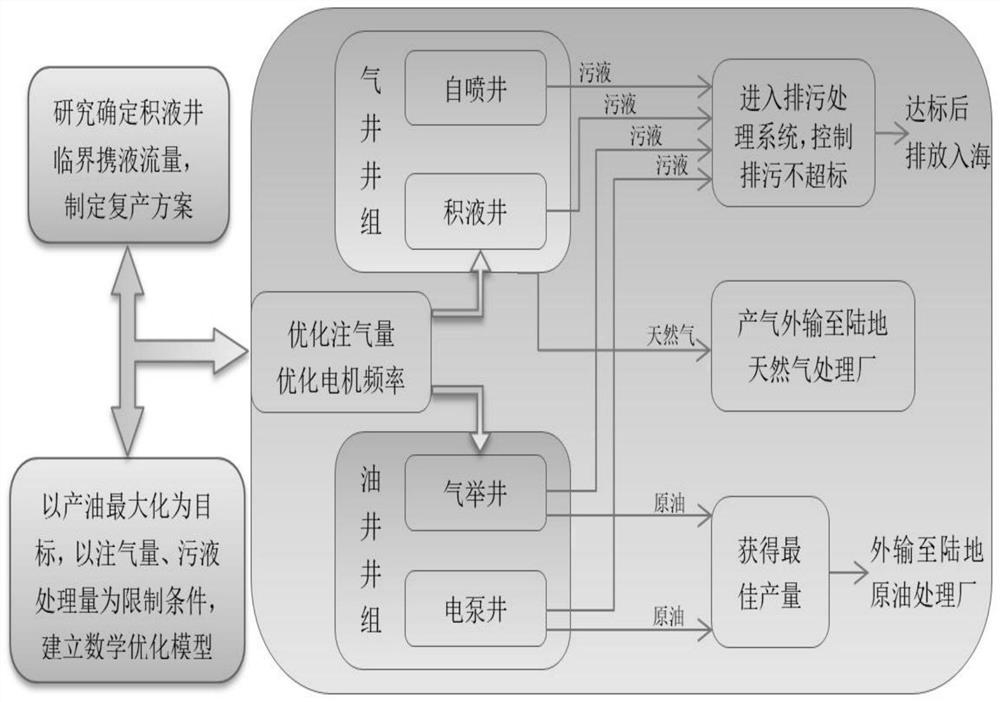

An optimization model and offshore platform technology, applied in design optimization/simulation, wellbore/well components, special data processing applications, etc., can solve problems affecting economic benefits, long-term stable production, production wells cannot be maintained, etc., to achieve flexibility Strong, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

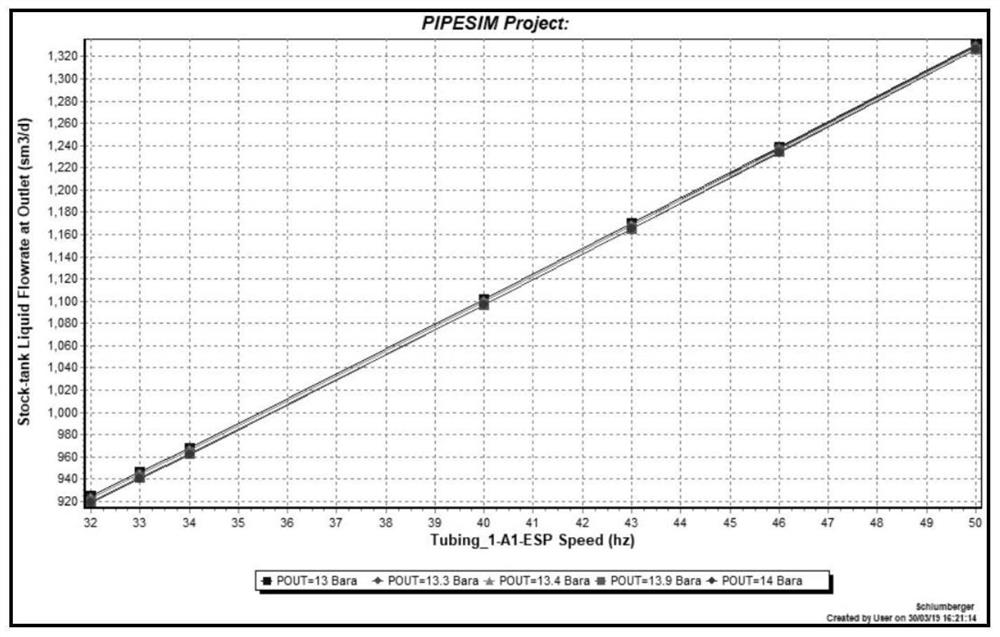

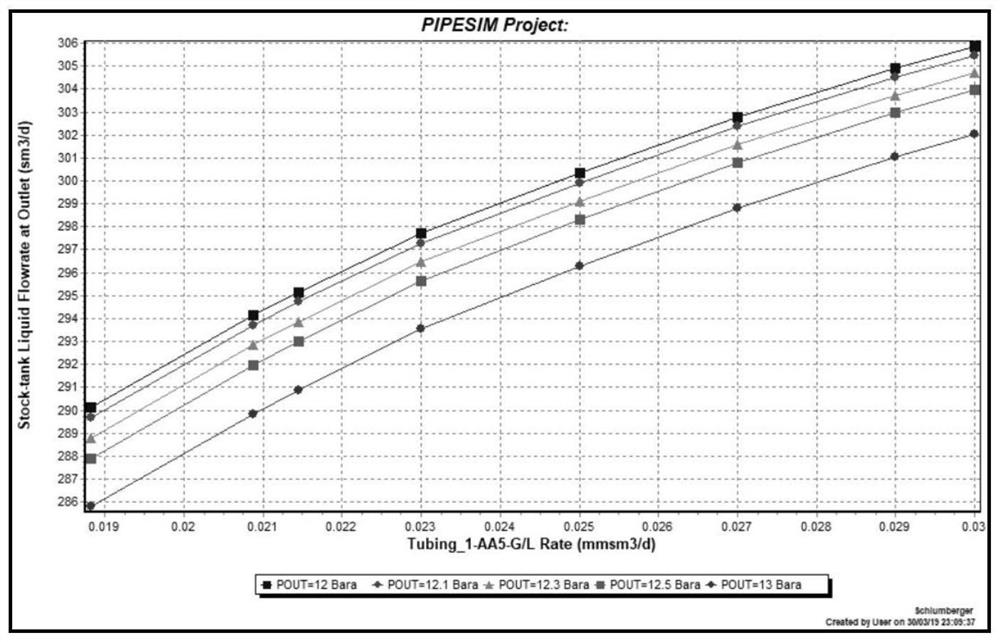

[0103] Assuming that the sewage treatment capacity is reduced to 5500m 3 / d, the total amount of gas injection is 10×10 4 m 3 / d, the gas injection volume of a single well shall not exceed 3×10 4 m 3 / d, the optimal displacement interval of the electric pump well is based on the performance test curve of the electric submersible pump, and the following three schemes are designed, see Table 3 (optimized design scheme 1), table 4 (optimized design scheme 2), and table 5 (optimized design scheme 3):

[0104] table 3

[0105]

[0106] As described in Example 1, the difference is the frequency of the electric pump well and the gas injection rate of the gas lift well.

[0107] Table 4

[0108]

[0109] As described in Example 1, the difference is the frequency of the electric pump well and the gas injection rate of the gas lift well.

[0110] table 5

[0111]

Embodiment 2

[0113] Assume that the upper limit of sewage treatment capacity is 5000m 3 / d, the total amount of gas injection is 8×10 4 m 3 / d, the gas injection volume of a single well shall not exceed 2.5×10 4 m 3 / d, the optimal displacement range of the electric pump well is based on the performance test curve of the electric submersible pump, and the following three schemes are designed, see Table 6 (optimized design scheme 4), table 7 (optimized design scheme 5), and table 8 (optimized design scheme 6):

[0114] Table 6

[0115]

[0116] As described in Example 2, the difference is the frequency of the electric pump well and the gas injection rate of the gas lift well.

[0117] Table 7

[0118]

[0119] As described in Example 2, the difference is the frequency of the electric pump well and the gas injection rate of the gas lift well.

[0120] Table 8

[0121]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com