Comprehensive coal mining device and method based on high-water filling material

A filling material and comprehensive technology, applied in the direction of filling, safety devices, ground mining, etc., can solve the problems of labor-intensive dismantling and laying work, prone to mine collapse, and reduce filling effect, so as to avoid laying work and reduce mine The risk of collapse, the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

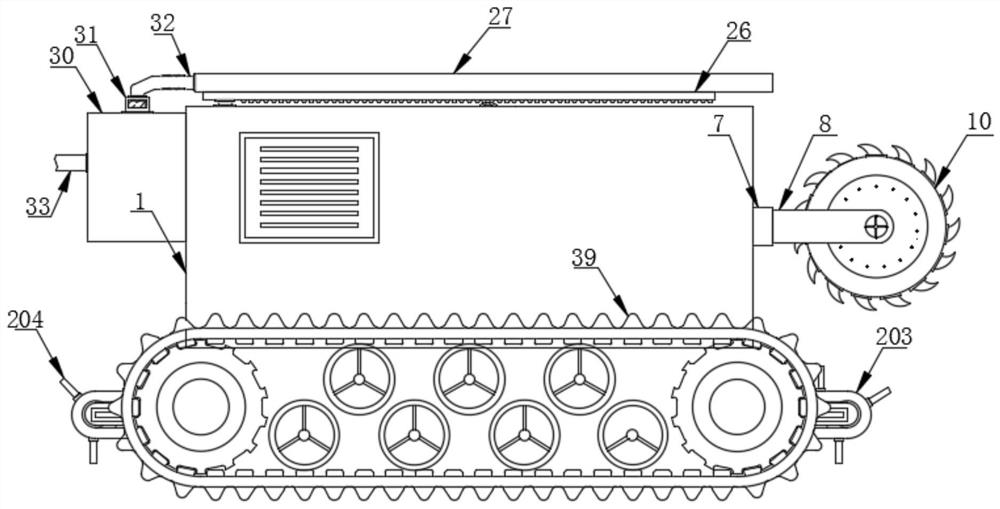

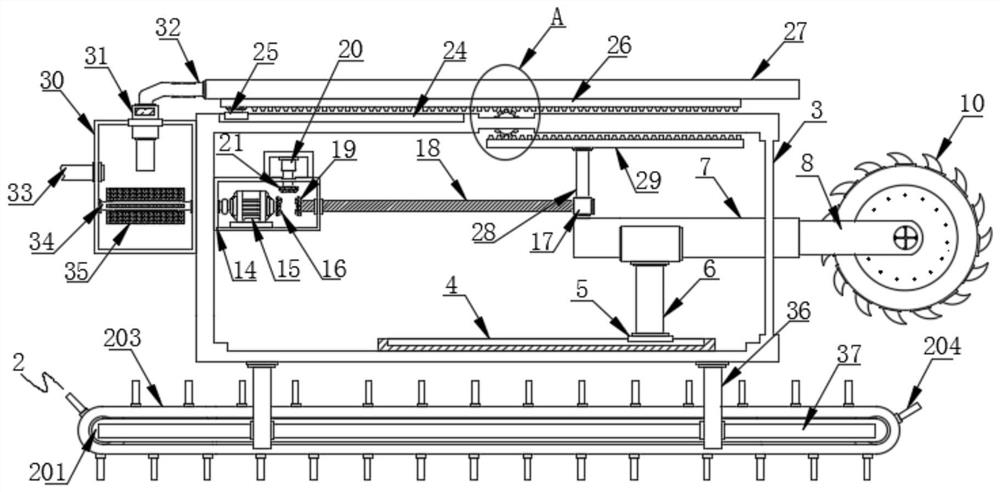

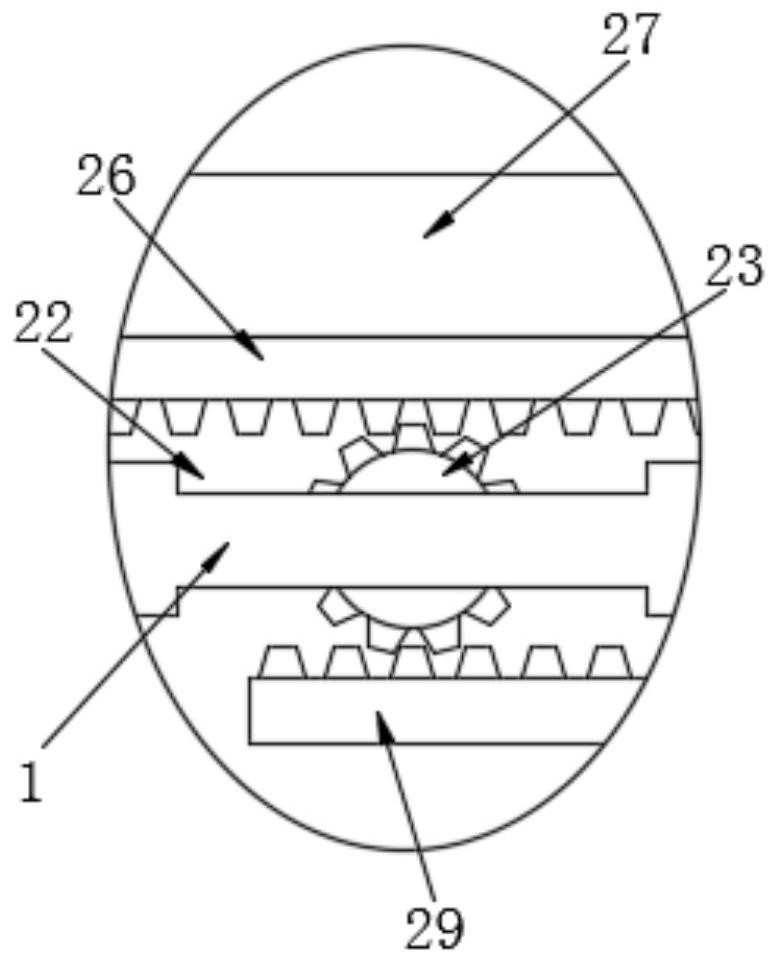

[0035] A comprehensive coal mining device based on high-water filling material, comprising a device chamber 1 and a transmission mechanism 2, the transmission mechanism 2 is driven by a drive motor, the right side of the device chamber 1 is provided with a through port 3, and the bottom of the inner cavity of the device chamber 1 is provided. A first chute plate 4 is fixedly connected to the right side, a first slider 5 is slidably installed inside the first chute plate 4, a support column 6 is fixedly connected to the top of the first slider 5, and the top of the support column 6 is fixed by The plate is fixedly connected with a load-bearing beam 7, the right side of the load-bearing beam 7 extends to the outside of the device room 1 through the through port 3, the front and rear parts of the right side of the load-bearing beam 7 are fixedly connected with a clamping plate 8, and the front part clamps The right side of the rear part of the plate 8 is rotatably connected to the...

Embodiment 2

[0038] A comprehensive coal mining device based on high-water filling material, including a device chamber 1 and a transmission mechanism 2, a through port 3 is opened on the right side of the device chamber 1, and a first slide is fixedly connected to the right side of the bottom of the inner cavity of the device chamber 1. The groove plate 4, the inside of the first chute plate 4 is slidably installed with a first slider 5, the top of the first slider 5 is fixedly connected with a support column 6, and the top of the support column 6 is fixedly connected with a load-bearing beam 7 through a fixed plate, The right side of the load-bearing beam 7 extends to the outside of the device room 1 through the opening 3, the front and rear parts of the right side of the load-bearing beam 7 are fixedly connected with a clamping plate 8, and the right side of the rear of the front clamping plate 8 passes through The bearing part is rotatably connected with a rotating drum 9, the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com