Hydraulic suspension type reactor shutdown rod and working method thereof

A reactor and shutdown rod technology, applied in the direction of reactors, nuclear reaction control, nuclear engineering, etc., can solve the problems of insufficient diversity design of shutdown methods, infeasibility of emergency boron injection, lack of shutdown measures, etc., to improve failure safety performance, achieve diversification, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

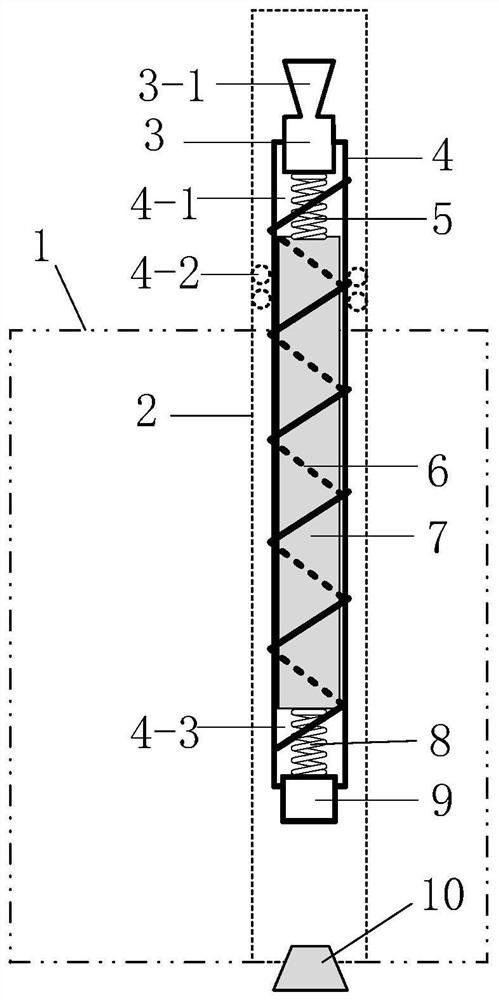

[0023] refer to figure 1 , the hydraulic suspension reactor shutdown rod of the present invention comprises an upper end plug 3, an operating joint 3-1, a cladding 4, an upper air chamber 4-1, a discharge hole 4-2, a lower air chamber 4-3, Upper compression spring 5, metal winding wire 6, neutron absorber 7, lower compression spring 8, lower end plug 9 and buffer device 10;

[0024] The control rod guide pipe 2 is installed in the reactor core 1, and the reactor core 1 is provided with a plurality of hydraulically suspended reactor shutdown rods and a plurality of control rod guide pipes 2 according to requirements.

[0025] There is a gap between the control rod guide tube 2 and the cladding 4 to form a coolant flow channel through which the shutdown rods are cooled. The side of the control rod guide tube 2 is provided with a drain hole 4-2, and the cladding 4 Metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com