Insulating collector plate and fuel cell

A fuel cell and collector plate technology, applied to fuel cells, fuel cell parts, circuits, etc., can solve problems affecting the performance and service life of the stack, poor sealing and insulation effects, and inability to achieve insulation, etc., to achieve overall Strong performance, reduced contact resistance, and reduced R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

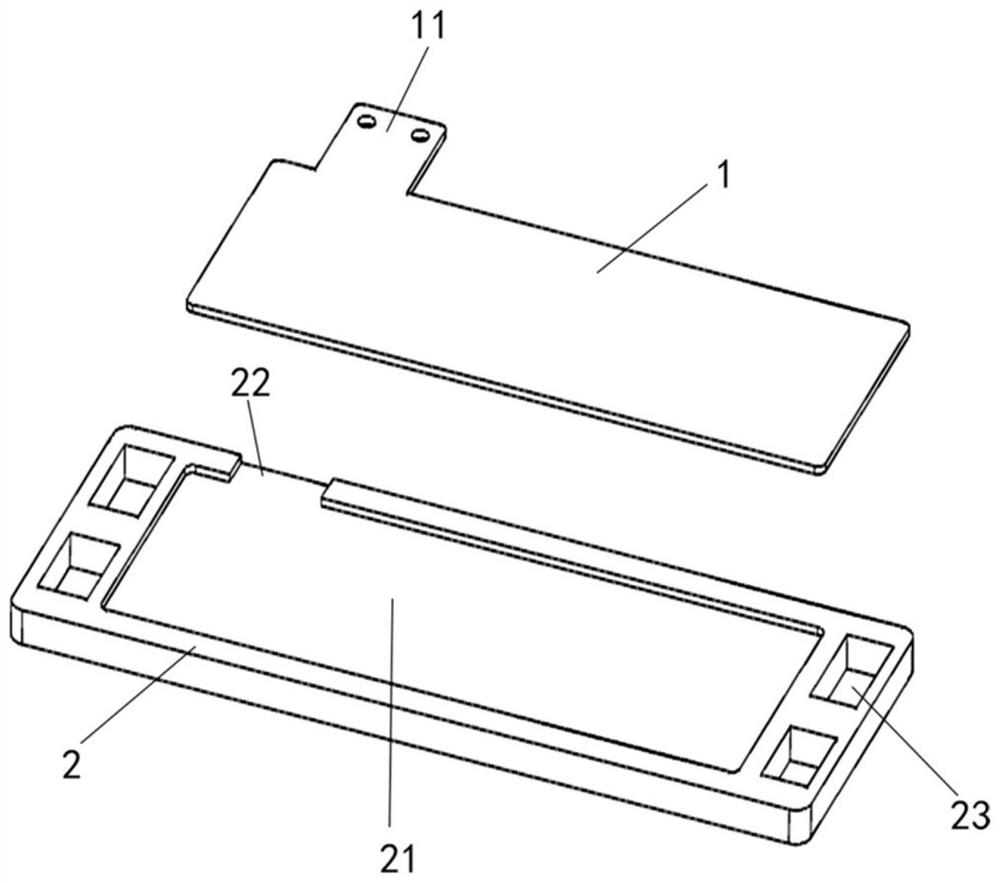

[0024] like figure 1 As shown, this embodiment provides an insulating current collector, including a board core module 1 and an insulating board module 2 . A groove structure 21 is provided in the center of the insulating board module 2 , and an opening groove 22 is provided on the upper edge of the insulating board module. One end of the opening groove 22 is connected to the groove structure 21 , and the other end extends to the edge of the insulating board module 2 . . The shape of the board core module 1 matches the shape of the groove structure 21 ; a lead-out end 11 is provided on one side of the board core module 1 . The board core module 1 is embedded in the groove structure 21 , the lead end 11 is embedded in the opening, and the length of the lead end 11 is greater than the length of the opening slot 22 , so that the end of the lead end 11 is suspended outside the insulating board module 2 .

[0025] In this embodiment, the thickness of the board-core module 1 is co...

Embodiment 2

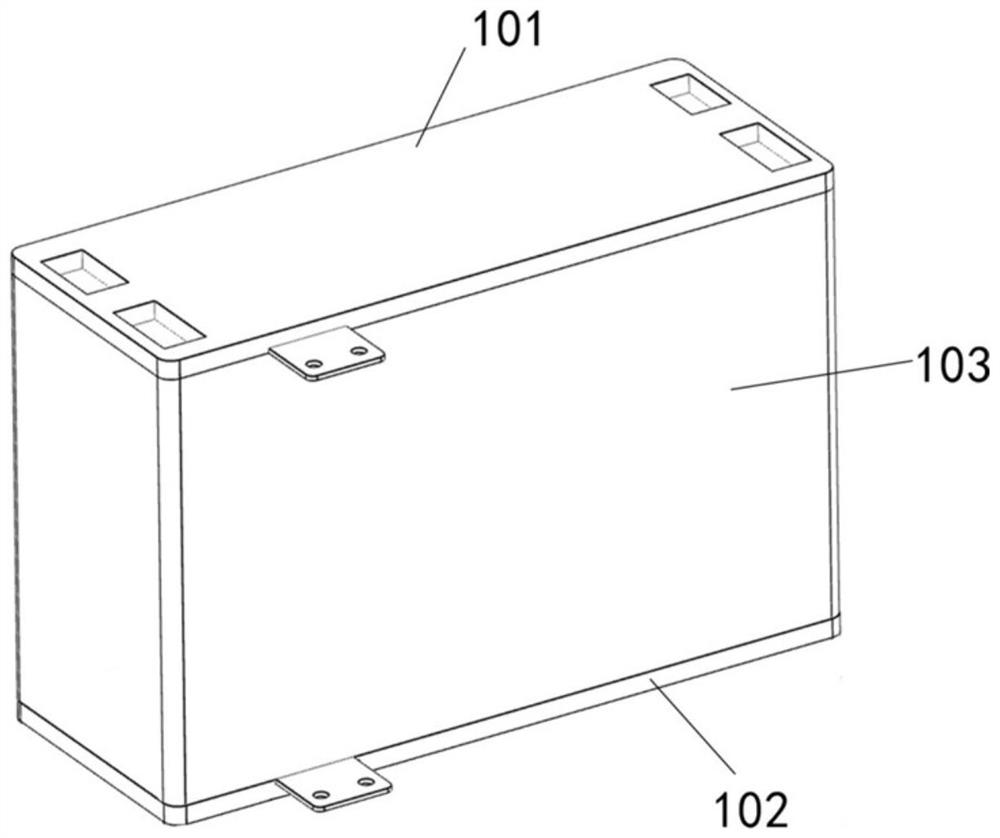

[0030] like figure 2 As shown, this embodiment provides a fuel cell including a casing (not shown in the figure), an insulating current collector plate and a core 103 . The insulating current collector plate in this embodiment is divided into an upper end current collector plate 101 and a lower end current collector plate 102 . The structure of the core is the same as that of the existing fuel cell core 103, so it is no longer unfolded. The structure of the upper current collecting plate 101 is the same as that of the insulating current collecting plate in the first embodiment. The structure of the lower-end current collecting plate 102 is similar to the structure of the insulating current collecting plate in the first embodiment, and the difference lies in that the two ends of the insulating plate module 2 are not provided with the through-hole structures 23 . The core 103 with insulating current collector plates at both ends is integrally installed in the casing. The fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com