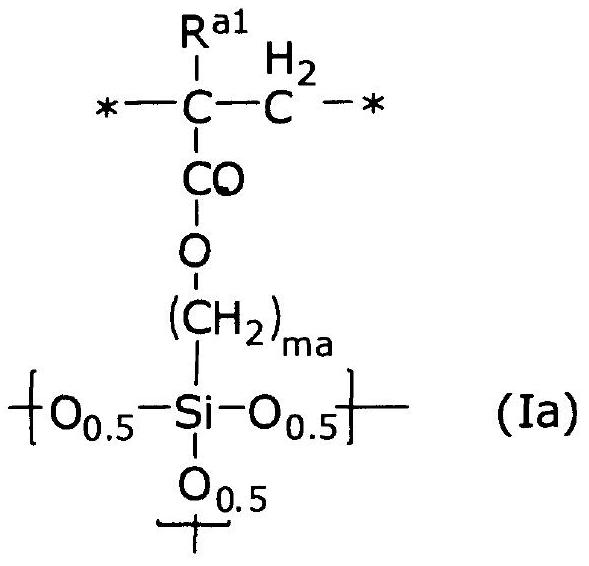

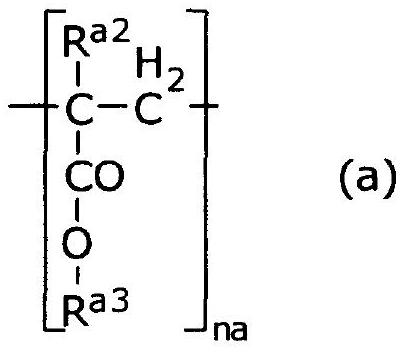

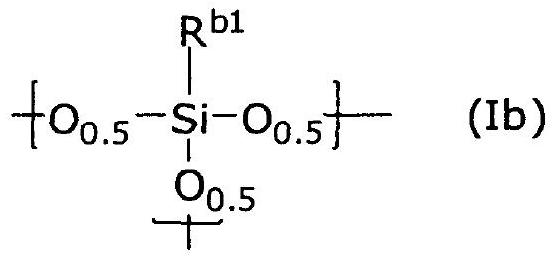

Acrylic polymerized polysiloxane, composition comprising same, and cured film produced using same

An acrylic and polysiloxane technology, applied in the field of acrylic polymerized polysiloxane, compositions containing it, and cured films using it, can solve problems such as complex wiring, difficult planarization, and difficult-to-handle materials , to achieve high heat resistance, excellent adhesion, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0246]

[0247] In a 100mL flask equipped with a stirrer, a thermometer, and a cooling tube, add 20.4g of the above-mentioned polysiloxane b solution and 0.205g of azabisisobutyronitrile, and stir at 80°C for 4 hours to obtain an acrylic polymer poly Silicone A solution.

[0248] The resulting acrylic polymerized polysiloxane A had a Mw of 7112 and an ADR of / Second.

Synthetic example 2

[0249]

[0250] Add 36.7g of 25% by mass TMAH aqueous solution, 600ml of IPA and 3.0g of water to a 2L flask equipped with a stirrer, a thermometer, and a cooling tube, then prepare 17g of methyltrimethoxysilane, 29.7g of phenyltrimethylsilane in a dropping funnel A mixed solution of oxysilane, 7.6 g of tetramethoxysilane, and 43.4 g of 3-(methacryloyloxy)propyltrimethoxysilane. The mixed solution was added dropwise at 40° C., and the mixture was stirred at the same temperature for 2 hours, and then neutralized by adding 10% aqueous HCl. 400 ml of toluene and 600 ml of water were added to the neutralized solution to separate into two layers, and the water layer was removed. The mixture was washed three times with 300 ml of water, the obtained organic layer was concentrated under reduced pressure to remove the solvent, and PGMEA was added to the concentrate so that the solid content concentration became 30% by mass to obtain a polysiloxane solution. Mw of the polysiloxane ob...

Synthetic example 3

[0253]

[0254] Add 42.8g of 25% by mass TMAH aqueous solution, 600ml of IPA and 3.5g of water to a 2L flask equipped with a stirrer, a thermometer, and a cooling tube, then prepare 27.2g of methyltrimethoxysilane, 29.7g of phenyl A mixed solution of trimethoxysilane, 7.6 g of tetramethoxysilane, and 24.8 g of 3-(methacryloyloxy)propyltrimethoxysilane. The mixed solution was added dropwise at 40° C., and the mixture was stirred at the same temperature for 2 hours, and then neutralized by adding 10% aqueous HCl. 400 ml of toluene and 600 ml of water were added to the neutralized solution to separate into two layers, and the water layer was removed. The mixture was washed three times with 300 ml of water, the obtained organic layer was concentrated under reduced pressure to remove the solvent, and PGMEA was added to the concentrate so that the solid content concentration became 30% by mass to obtain a polysiloxane solution. The Mw of the polysiloxane obtained at this stage is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com