Plasticizer composition, and vinyl chloride-based resin composition comprising same

A resin composition and composition technology, applied in the field of plasticizer composition and vinyl chloride-based resin composition containing it, can solve the problems of low flexibility, easy cracking, deterioration of plasticizing effect of plasticizer, etc. To solve environmental problems and improve the effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

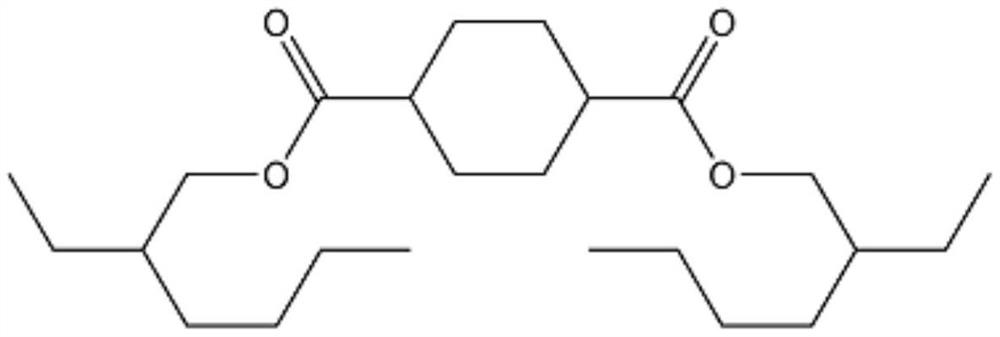

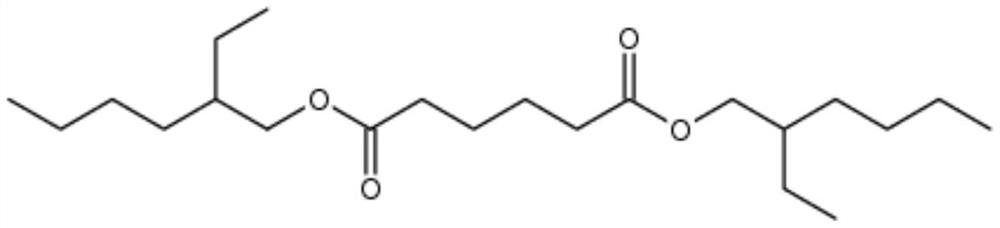

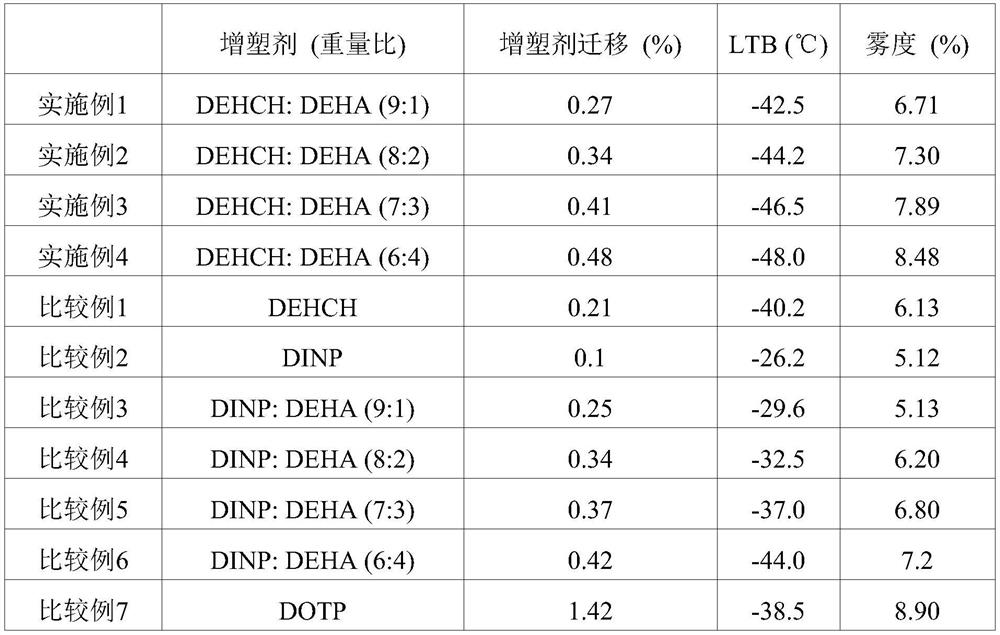

[0069] Mix bis(2-ethylhexyl)cyclohexane-1,4-dicarboxylate (DEHCH) and bis(2-ethylhexyl)adipate (DEHA) in a weight ratio of 9:1 to prepare a plasticizer combination.

[0070] 100 parts by weight of polyvinyl chloride, 60 parts by weight of plasticizer composition, 2.0 parts by weight of heat stabilizer (Songwon Industrial), 1.5 parts by weight of BZ-150T, 0.5 parts by weight of BP-251S ), 2 parts by weight of an epoxy auxiliary thermal stabilizer (Matsubara Industrial Co., Ltd., E-700) were weighed and mixed with a mixer, and then kneaded with a roller mill, thus prepared.

Embodiment 2 to 4

[0072]Mix bis(2-ethylhexyl)cyclohexane-1,4-dicarboxylate (DEHCH) and bis(2-ethylhexyl)adipate (DEHA) in the weight ratio described in Table 1 below to Each plasticizer composition was prepared.

[0073] After that, each vinyl chloride-based resin composition was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com