Continuous flow microbioreactor

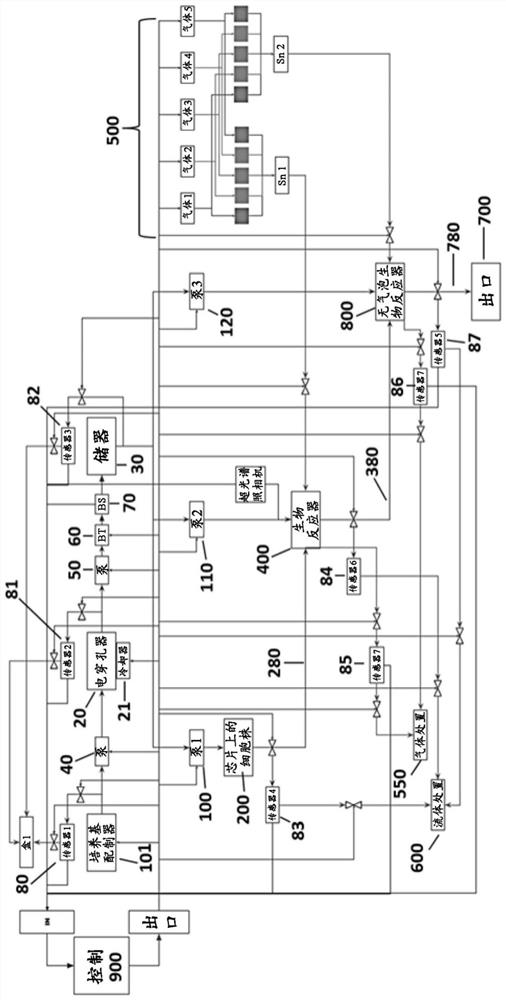

A bioreactor, miniature technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, enzymology/microbiology device, etc., can solve the problem of different environments, large physical space, suboptimal length and production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0208] Example 1: Simulation of Fluid Flow and Mixing in Layers of Micromodules

[0209] Given that the flow is laminar, the simulation can be addressed in two situations; on the one hand, the velocity field, and on the other hand, the convective-diffusion transport of the microorganisms to be analyzed. In this case, it was decided to use two species (S1 and S2), which enter each branch of the inlet of the module at a certain concentration, or branches of the inlet of differently coupled modules. Diffusion values were determined from the diffusion coefficient of fluorescein in water for S1 and 2 orders of magnitude lower for S2.

[0210] Progression and mixing between streams was simulated considering a constant average inflow velocity of 5 micrometers per second (μm / sec), and species concentrations were tracked from the outlet through the entire section. An inflow concentration value of 50% is expected to be good mixing, assuming that the flow rates are equal for both infl...

Embodiment 2

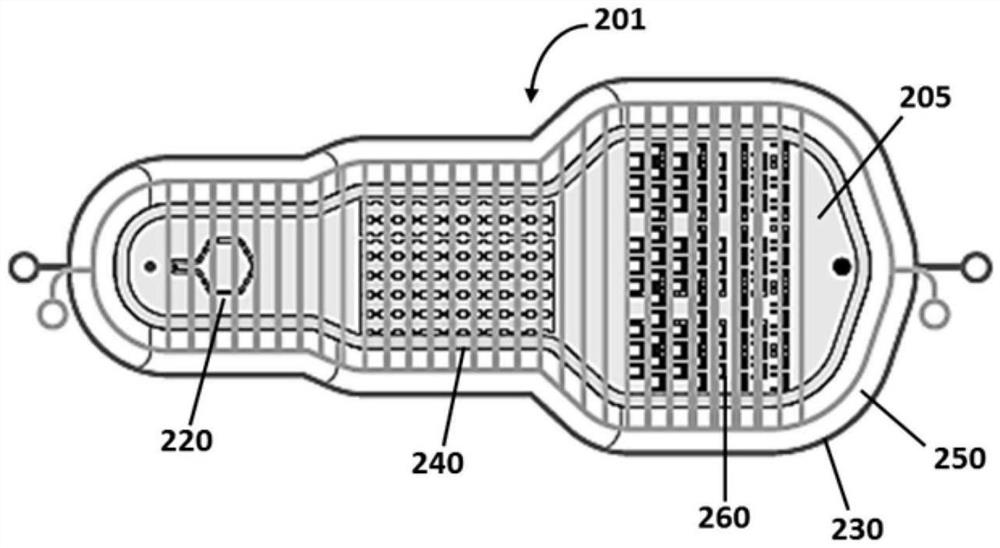

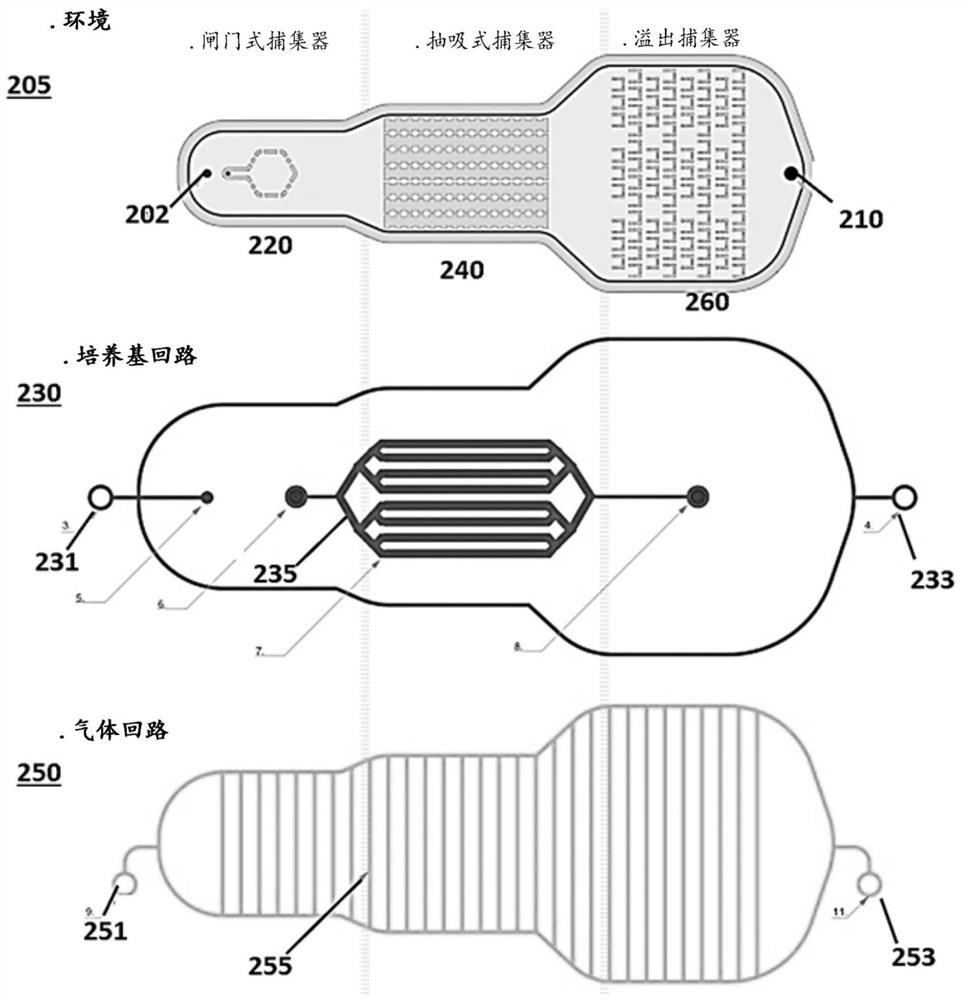

[0212] Embodiment 2: build the macroscopic structure of micromodule

[0213] The bioreactor uses the Figure 24 The macrostructure shown in was designed, including layers of DG micromodules and with the feed loop shown. An SLA 3-D printer (Peopoly Moai) with commercial resin was used for 3-D printing, including all systems and connections. The printed bioreactor is shown in cross-section in Figure 23A and 23B middle.

[0214] Additional bioreactors were printed with SLA printers and photocurable resins. The design includes two phases, the "masculine form" (the volume of the two phases that are entangled without an intermediate membrane). Figure 25A An isometric view is shown of the test file used, comprising several layers of double helix tetrahedron (diameter: 600 micrometers (μm)) and a solid base for better handling. Note that the feed system for each phase is not located. Figure 25B Test files showing successful printing on PEGDA photocurable resin, Figure 25C ...

Embodiment 3

[0215] Example 3: Demonstration of fluid flow through a micromodule

[0216] A Direct Light Projection type 3-D printer with commercial resin was used to print the substrate comprising 4 layers with input / output connections and 4x2 module rows, where the diameter of the helical icosahedra is 500 μm). The printed bioreactor is injected with red dye at one input connection. Figure 26A A circuit saturated with red dye is shown. The second print included a first substrate and a second substrate to form a double helical icosahedron, both of which had a diameter of 500 μm. One matrix was injected with red dye at the input connection and the other matrix was injected with blue dye. Figure 26B 2 substrates are shown differentiated by color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap