Capacitive coupling in a direct-bonded interface for microelectronic devices

A microelectronic device, capacitive coupling technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problem of relying on discrete capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] overview

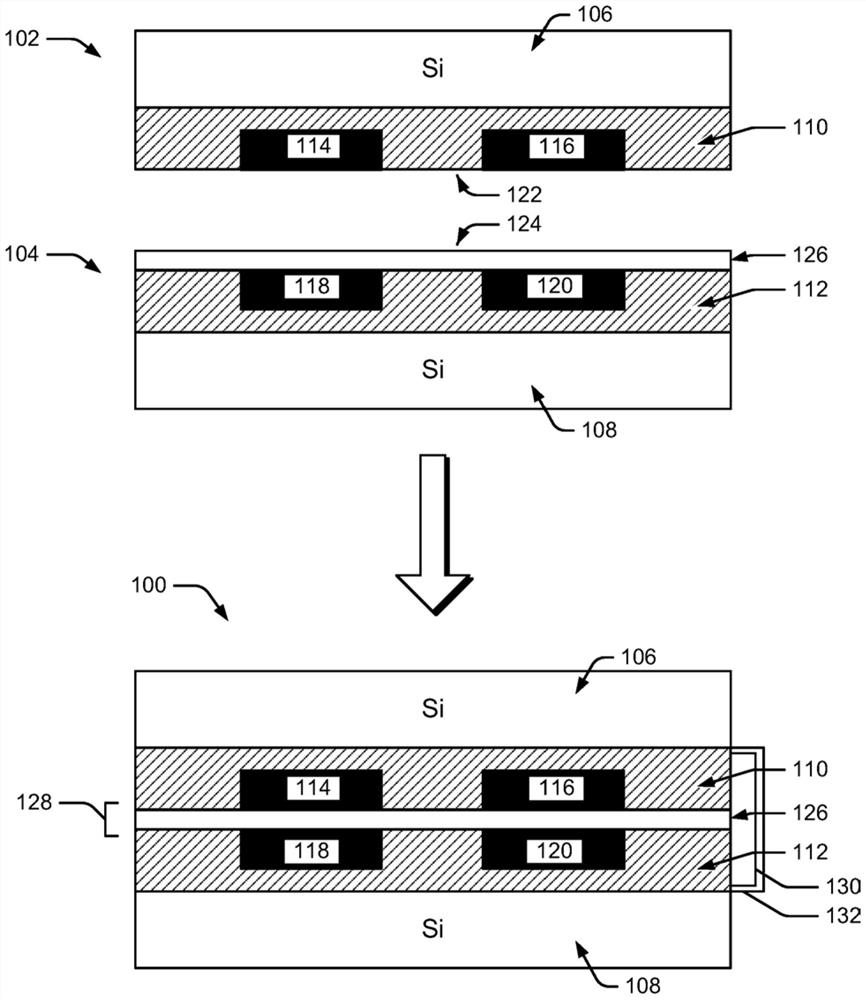

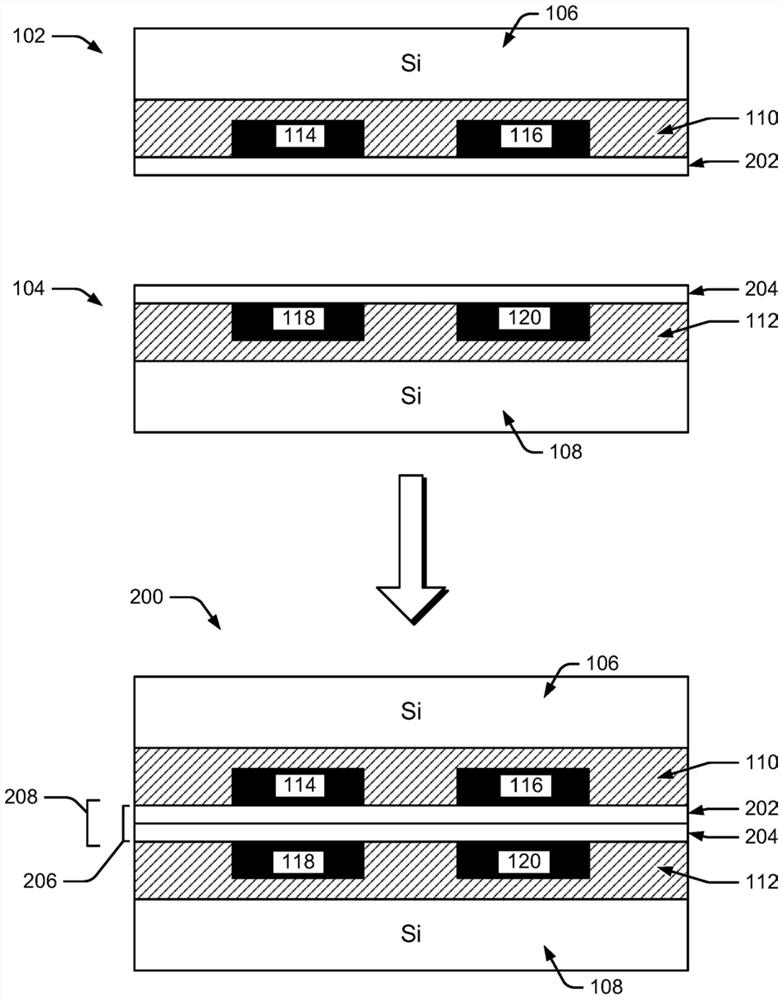

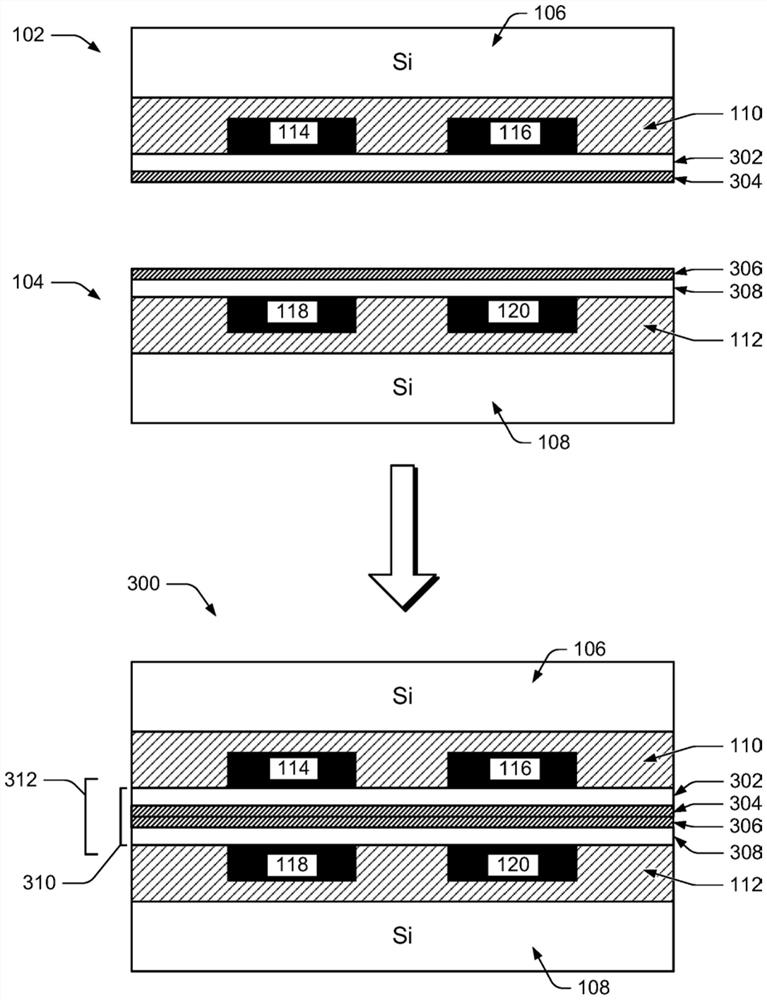

[0020] The present disclosure describes capacitive coupling in interfaces for direct bonding of microelectronic devices. The direct hybrid bonding process used for microelectronic dies and wafers also creates capacitive coupling for each individual signal line at the bonding interface. In one embodiment, the direct hybrid bonding process produces a direct bond between the dielectric surfaces of the two dies, a direct bond between the corresponding power interconnects of the two dies, and a direct bond between the corresponding ground interconnects of the two dies. Direct bonding occurs between interconnects and capacitive coupling occurs for each signal line at the bonding interface of the direct hybrid bonding process.

[0021] The direct bonding between the dielectric surfaces may be an oxide-oxide direct bonding. The direct bond between the corresponding power interconnects is a direct metal-to-metal bond. A direct bond between corresponding ground inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com