Catalyst for preparing 1,2-dimethylimidazole and preparation method thereof

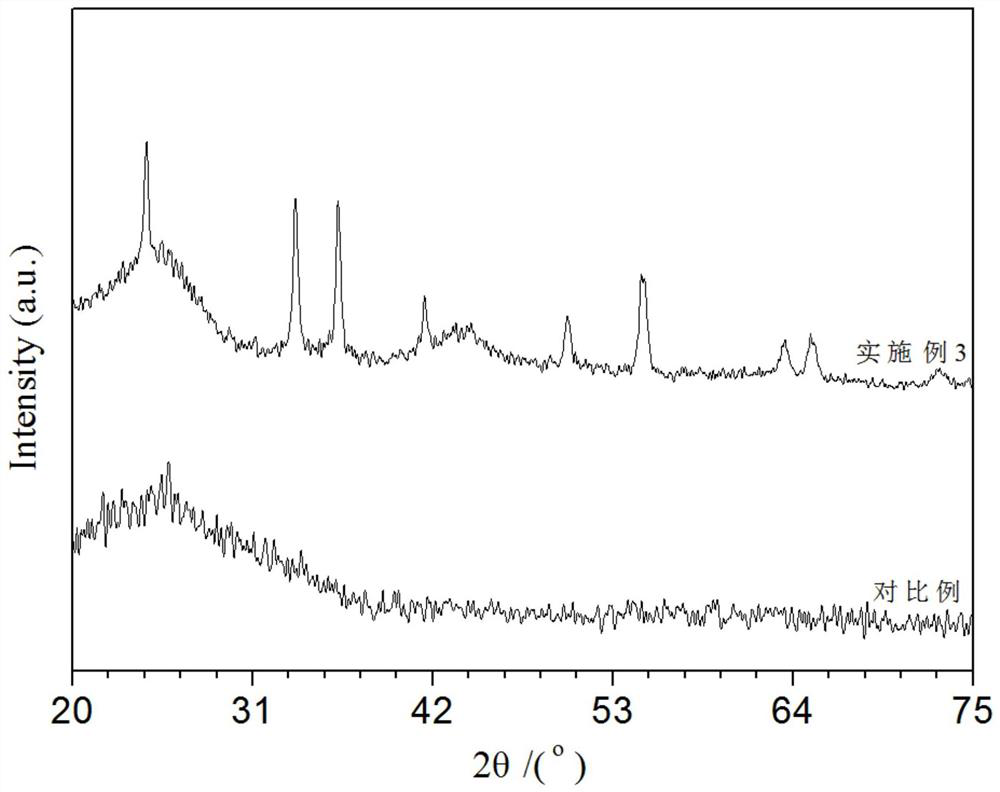

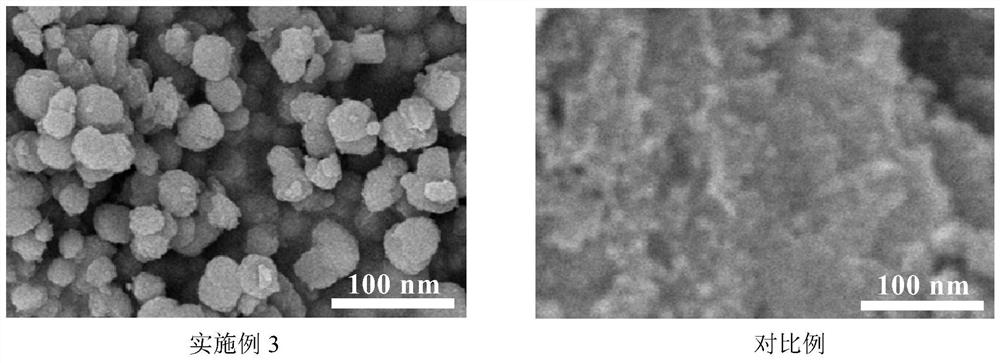

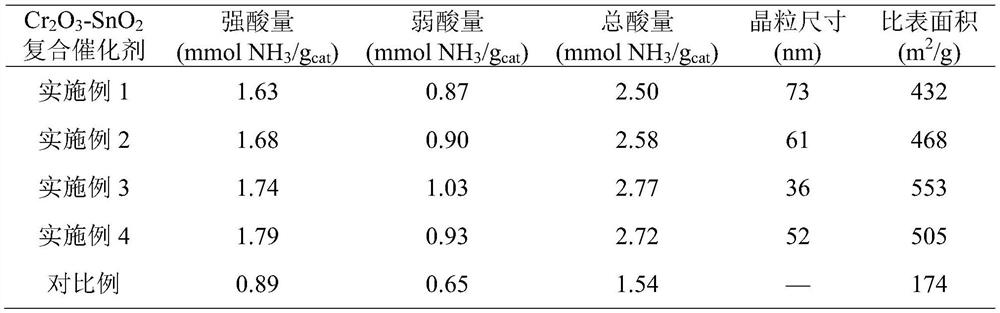

A technology of dimethylimidazole and catalyst, which is applied in the field of preparation of solid acid catalytic materials, can solve the problem of low yield of 1,2-dimethylimidazole, complex catalyst preparation method, high yield of 1,2-dimethylimidazole, etc. problems, to achieve the effect of rich acid content, short preparation time and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] With 9.52g chromium nitrate (consumption is represented by Cr 2 o 3 Calculation), 8.5g ammonia water (dosage is expressed as NH 3 Calculation), 44.1g tetraethylammonium hydroxide (TEAOH), 72g deionized water, the molar ratio is Cr 2 o 3 :NH 3 :TEAOH:H 2 O=1:25:15:200 mixed, at room temperature with a stirring rate of 80r / min stirring for 3h, to obtain the first solution; according to SnO 2 :Cr 2 o 3 =1:1 molar ratio, with 5.34g sodium stannate (consumption is based on SnO 2 Calculation) and 21.6g deionized water, in molar ratio for SnO 2 :H 2 O=1:60 mixing, stirring at room temperature at a stirring rate of 80r / min for 1h to obtain the second solution; adding the second solution dropwise to the first solution at a rate of 1.5mL / min, at a temperature of 60°C Stir at a stirring rate of 80r / min for 1h to form a sol-gel; transfer the sol-gel into a supercritical reactor, and feed carbon dioxide gas into the reactor to make the reactor reach a supercritical tempera...

Embodiment 2

[0027] With 10.64g chromium chloride (consumption is represented by Cr 2 o 3 Calculation), 10.2g ammonia water (dosage is expressed as NH 3 Calculation), 81.2g tetrapropyl ammonium hydroxide (TPAOH), 90g deionized water, the molar ratio is Cr 2 o 3 :NH 3 :TPAOH:H 2 O=1:30:20:250 mixing, stirring at room temperature at a stirring rate of 120r / min for 1h to obtain the first solution; press SnO 2 :Cr 2 o 3 =1:4 molar ratio, with 0.95g stannous chloride (consumption is based on SnO 2 Calculation) and 9.0g deionized water, in molar ratio for SnO 2 :H 2 O=1:100 mixing, stirring at room temperature at a stirring rate of 100r / min for 1h to obtain the second solution; adding the second solution dropwise to the first solution at a rate of 2.0mL / min, at a temperature of 80°C Stir at a stirring rate of 120r / min for 3 hours to form a sol-gel; transfer the sol-gel into a supercritical reactor, and feed carbon dioxide gas into the reactor to make the reactor reach a supercritical t...

Embodiment 3

[0029] With 10.64g chromium chloride (consumption is represented by Cr 2 o 3 Calculation), 9.52g ammonia water (dosage is expressed as NH 3 Calculation), 93.24g tetrabutylammonium hydroxide (TBAOH), 79.2g deionized water, Cr 2 o 3 :NH 3 :TBAOH:H 2 O=1:28:18:220 mixed, at room temperature with a stirring rate of 100r / min stirring for 3h, to get the first solution; according to SnO 2 :Cr 2 o 3 =1:2 molar ratio, with 2.67g sodium stannate (consumption is based on SnO 2 Calculation) and 14.4g deionized water, in molar ratio for SnO 2 :H 2 O=1:80 mixing, stirring at room temperature at a stirring rate of 100r / min for 3h to obtain the second solution; adding the second solution dropwise to the first solution at a rate of 1.8mL / min, at 90°C Stir at a stirring rate of 100r / min for 3 hours to form a sol-gel; transfer the sol-gel into a supercritical reactor, and feed carbon dioxide gas into the reactor to make the reactor reach a supercritical temperature of 100°C and a press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap