Bending machine and bending method of baking cup mat steel sheet

A technology for a bending machine and a steel sheet, applied in the field of steel processing, can solve the problems of low arc bending or rolling efficiency of the bending machine, the middle part of the steel sheet cannot be placed normally, and the special-shaped part cannot pass through, etc. Versatility and degree of automation, quick adjustment, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

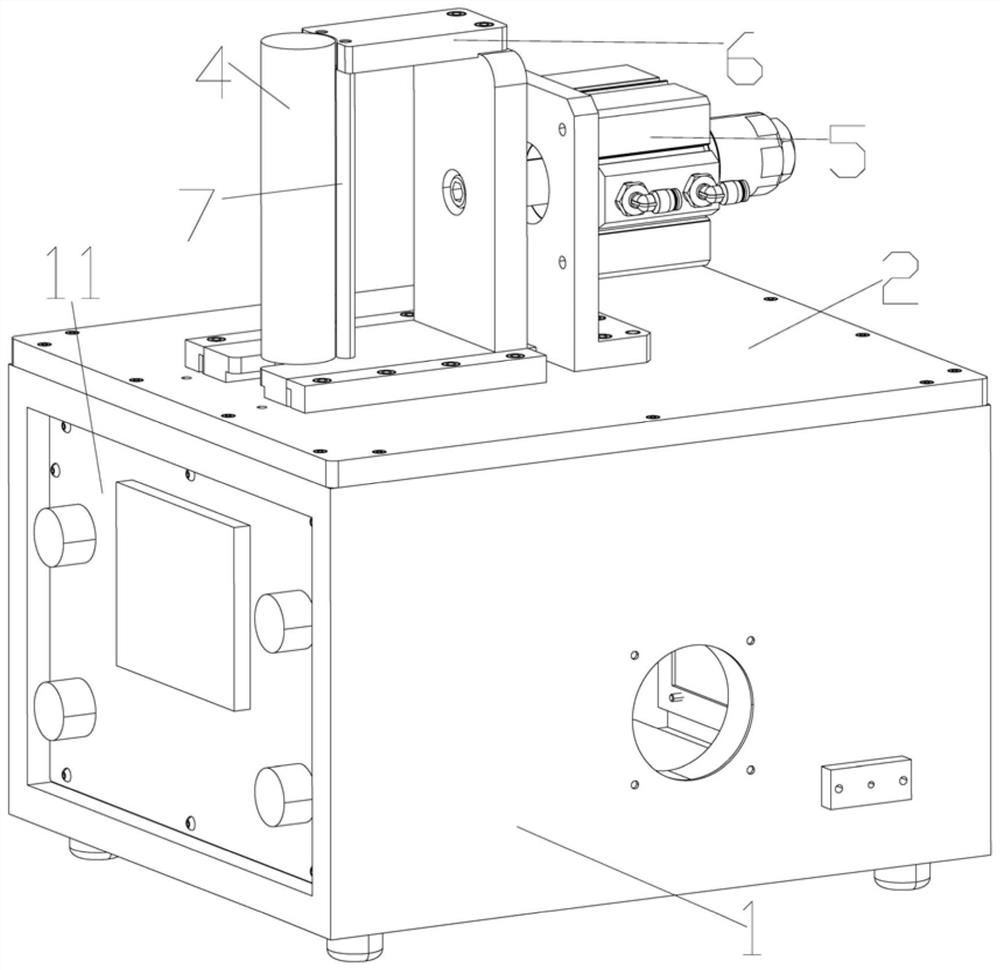

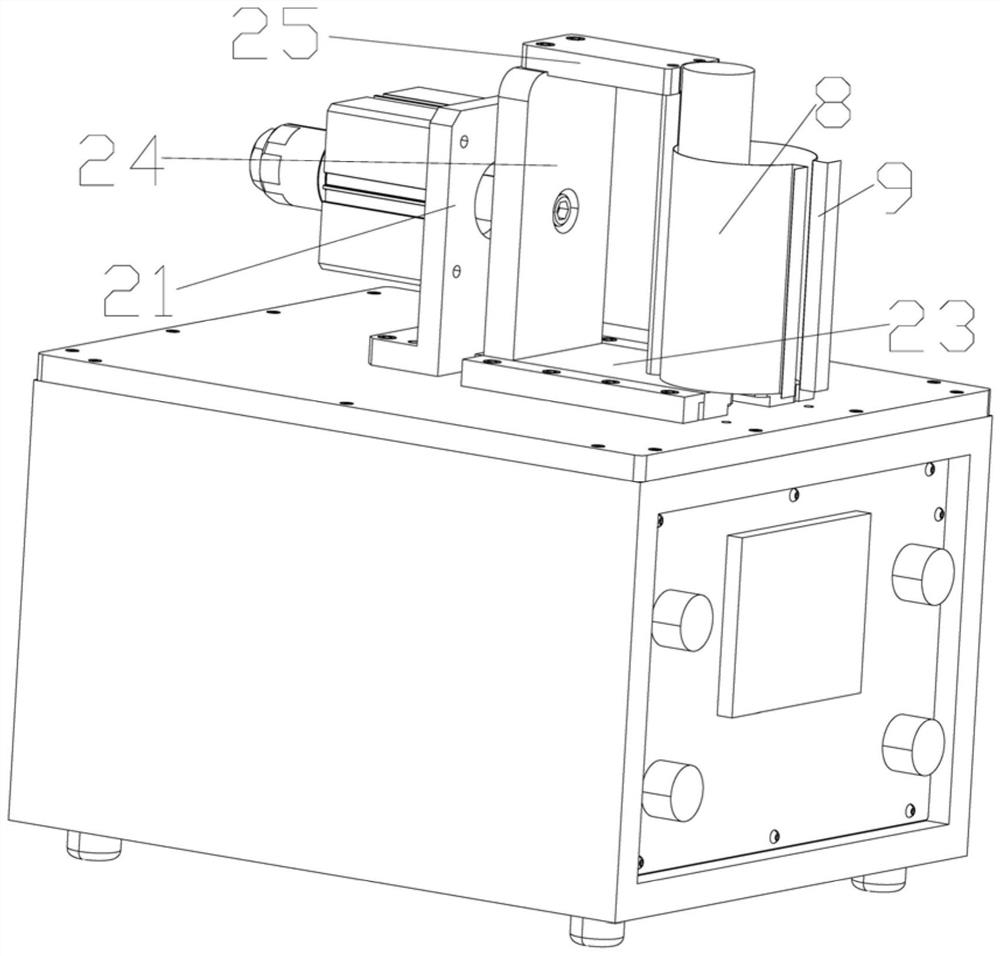

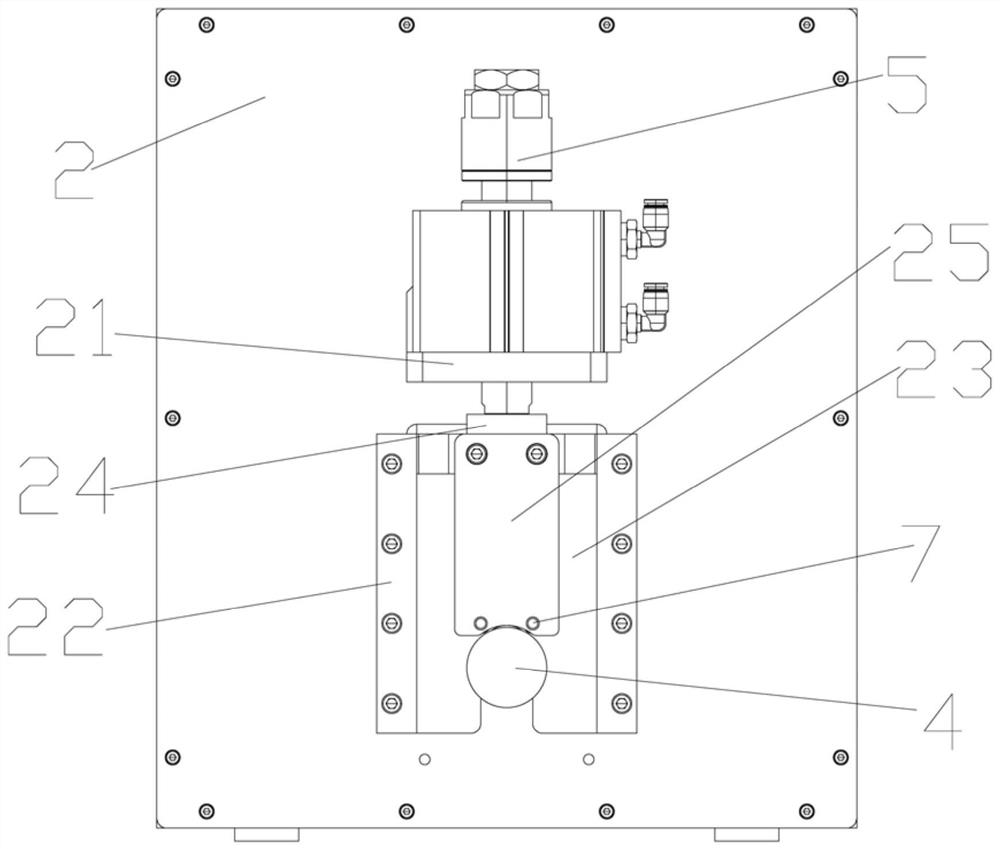

[0032] Such as Figure 1 to Figure 6 As shown, a bending machine provided by the present invention includes a chassis 1, a base 2 arranged above the chassis 1, a driving device 3 installed in the chassis 1, a driving device 3 located above the base 2 and connected to the driving device 3 The driving roller 4 at the output end of the base and the driving device 2 5 and the driven roller device that are all arranged on the top of the base 2, and the driven roller device includes an adjustment mechanism that is movably arranged on the top of the base 2 and connected with the output end of the driving device 2 5 6 and two driven rollers 7 parallel to and corresponding to the driving roller 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com