Magnetic liquid metal preparation method, micro gripper and clamping method

A liquid metal, micro-grip technology, applied in chucks, manufacturing tools, micro-manipulators, etc., can solve the problems of lack of variable stiffness and inability to directly apply flexible robot grippers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

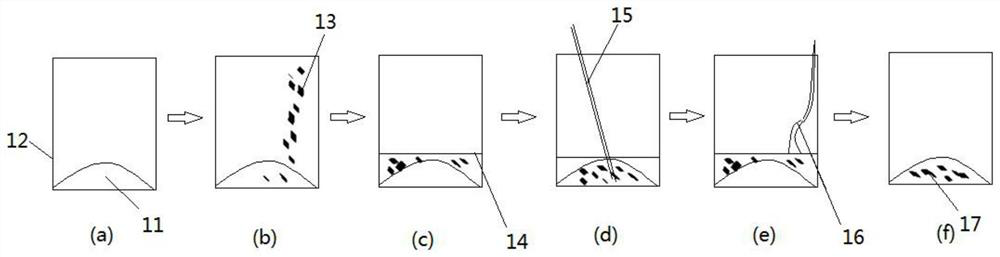

[0032] Such as figure 1 Shown, a kind of magnetic liquid metal preparation method of the present invention, it comprises the following steps:

[0033] 1) Take the liquid metal 11 whose weight part is A and put it into the container 12, as shown in figure (a);

[0034] 2) Take the metal powder 13 that is B by weight and put it into the container 12, as shown in figure (b); wherein the optimal value of the ratio of A and B is 10:3; the metal powder 13 is a single non-magnetic ferromagnetic Metals or mixtures of at least one non-magnetic ferromagnetic metal and other metals, such as iron powder, or copper-iron alloy powder, the particle size of the metal powder is about 100nm;

[0035] 3) Add hydrochloric acid 14 into the container until the liquid metal and metal powder are submerged, as shown in figure (c); hydrochloric acid is used to remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com