Method for preparing nano fluorescence thermometer

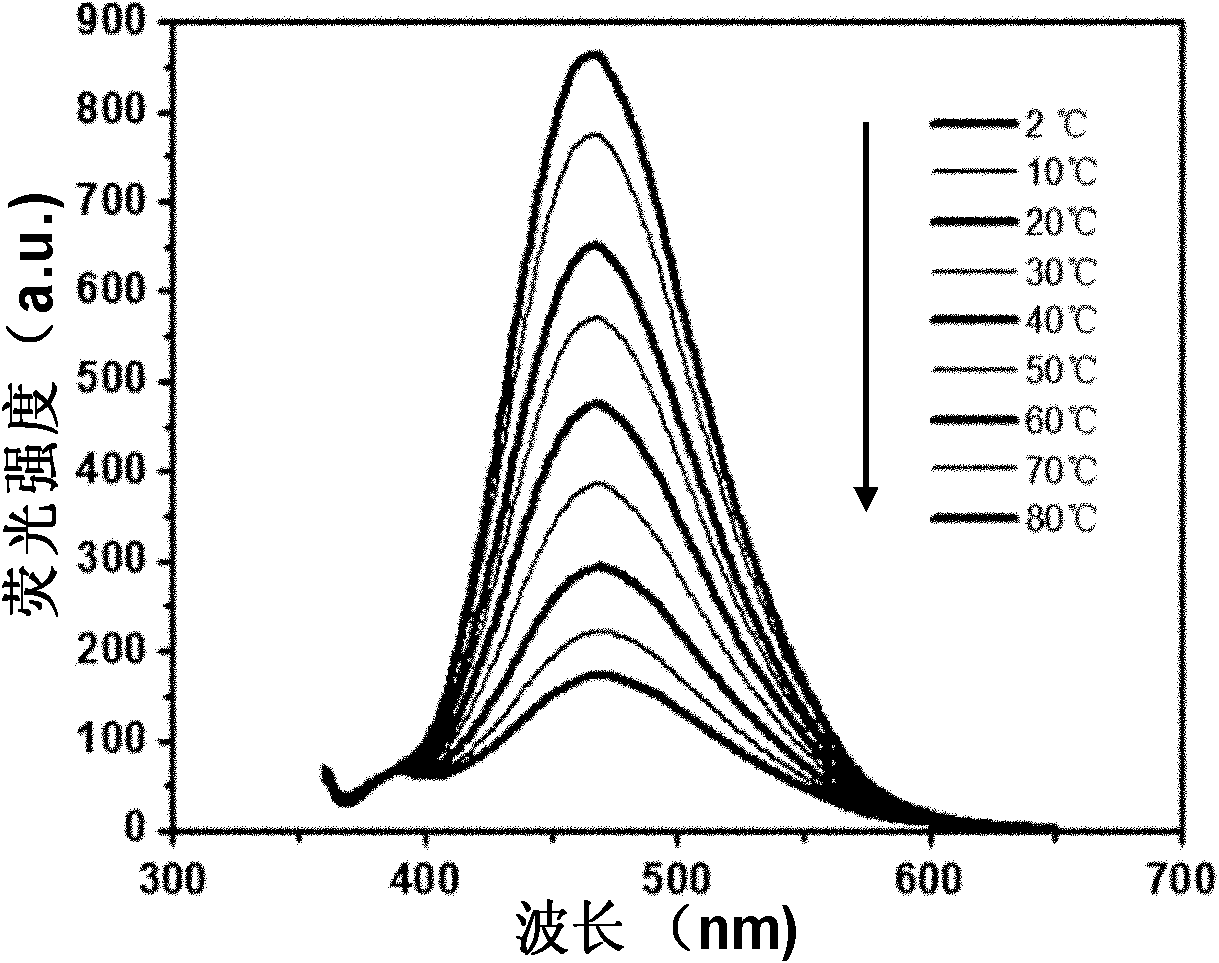

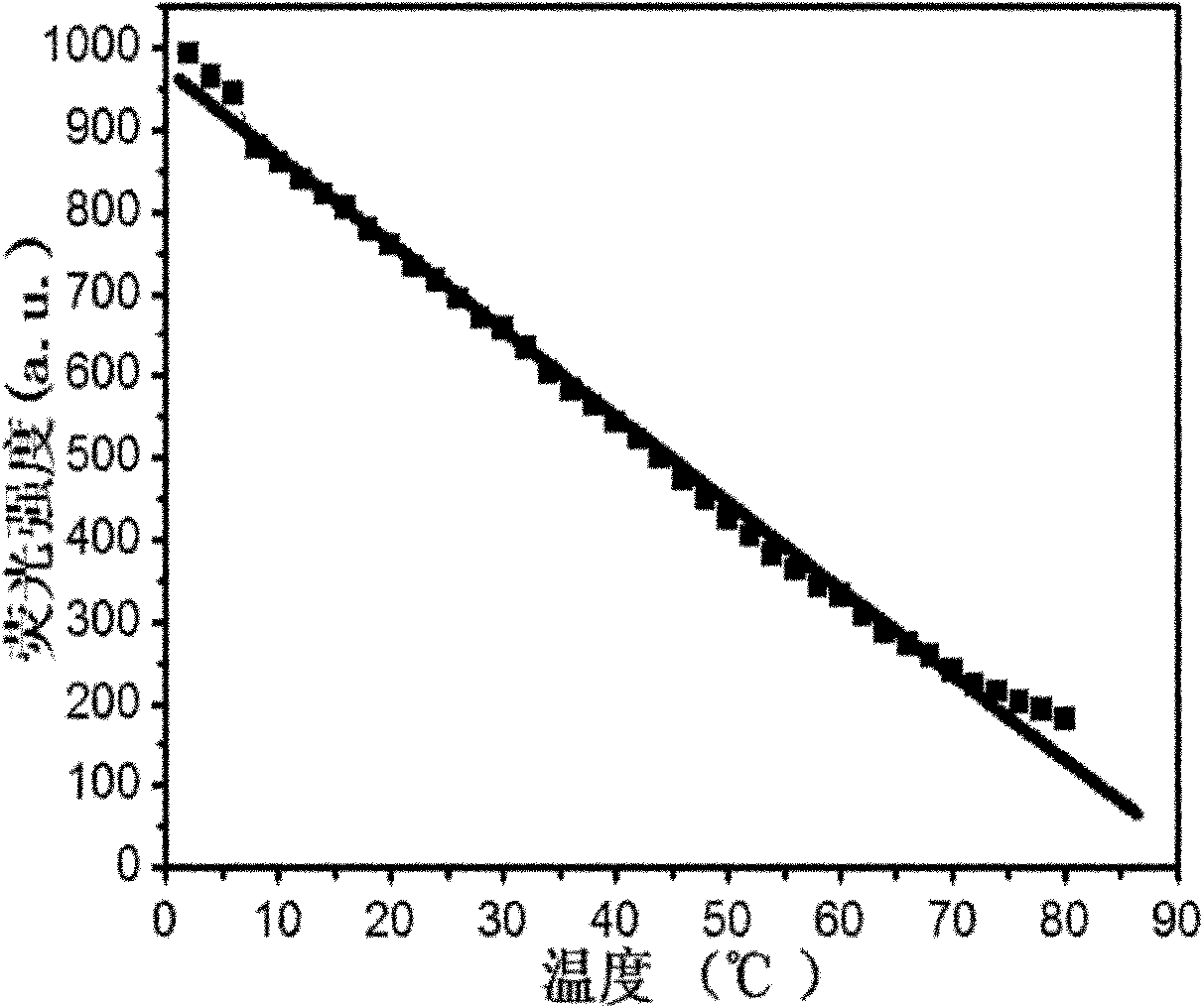

A nano-fluorescence and thermometer technology, which is applied in the field of preparation of fluorescent nano-thermometers, can solve the problems of limiting the applicability of AIE molecules, limiting internal rotation, and reducing non-radiative transitions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

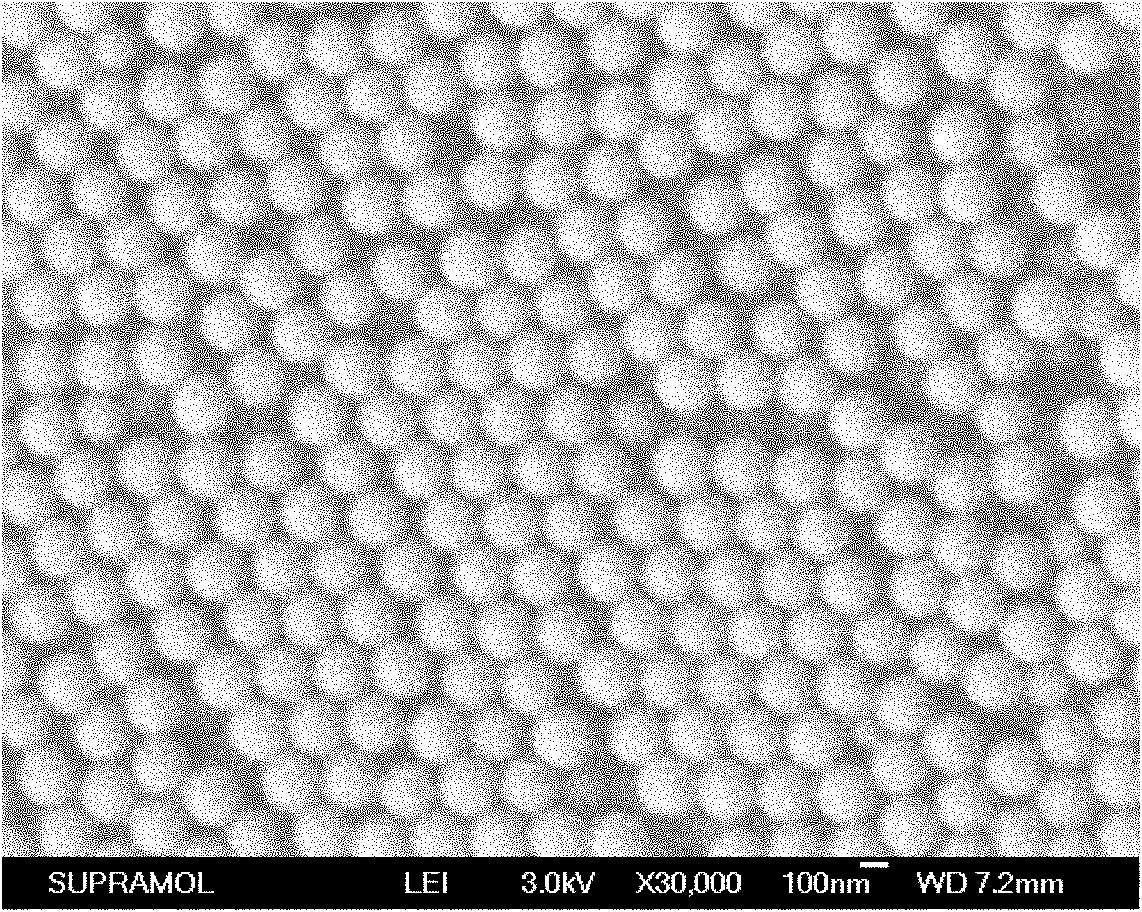

[0021](1) In a reactor containing 185ml of distilled water, weigh 0.5g of NIPAM and add it, and then add 4ml of styrene polymerized monomer after it is completely dissolved, stir vigorously at a speed of 300 rpm at room temperature, and discharge oxygen for 30 minutes with nitrogen gas, Then be warming up to 70 DEG C, then add 15 ml of aqueous solution containing 0.15 g potassium persulfate to initiate polymerization, the solution gradually becomes milky white emulsion from clarification, the reaction is maintained at 70 DEG C, stirred, and carried out for 12 hours, then down to room temperature and filtered with ordinary filter paper, A polymer emulsion is obtained. The polymer emulsion was repeatedly centrifuged and washed with distilled water for 3 times, and diluted with distilled water to finally obtain a 100ml emulsion of polymer nanospheres;

[0022] (2) Disperse all the polymer nanospheres obtained in step (1) into a reactor containing 185ml of distilled water, weigh 4...

Embodiment 2

[0025] (1) In a reactor containing 185ml of distilled water, weigh 2.0g of VCL and add it. After completely dissolving, add 5ml of styrene polymerized monomer. Stir vigorously at room temperature at a speed of 400 r / min. Pass nitrogen to exhaust oxygen for 50 minutes. Then be warming up to 80 DEG C, then add 15 ml of aqueous solution containing 0.20 g ammonium persulfate to initiate polymerization, the solution gradually becomes a milky white emulsion from clarification, the reaction is maintained at 80 DEG C, stirred, and carried out for 15 hours, then down to room temperature and filtered with ordinary filter paper, A polymer emulsion is obtained. Repeatedly centrifuging and washing the product 4 times with distilled water to obtain polymer nanospheres;

[0026] (2) Redisperse all the polymer microspheres obtained in step (1) into a reactor containing 185ml of distilled water, weigh 5.0g of VCL, and add 0.20ml of MA into the reaction vessel, stir vigorously, and remove nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com