Kinematics Modeling and Distributed Control Method of Multi-Mobile Manipulator Cooperative Handling System

A technology of mobile manipulators and handling systems, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as the inability to guarantee the consistency and stability of multi-mobile manipulators, and the inability to effectively establish kinematic expressions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

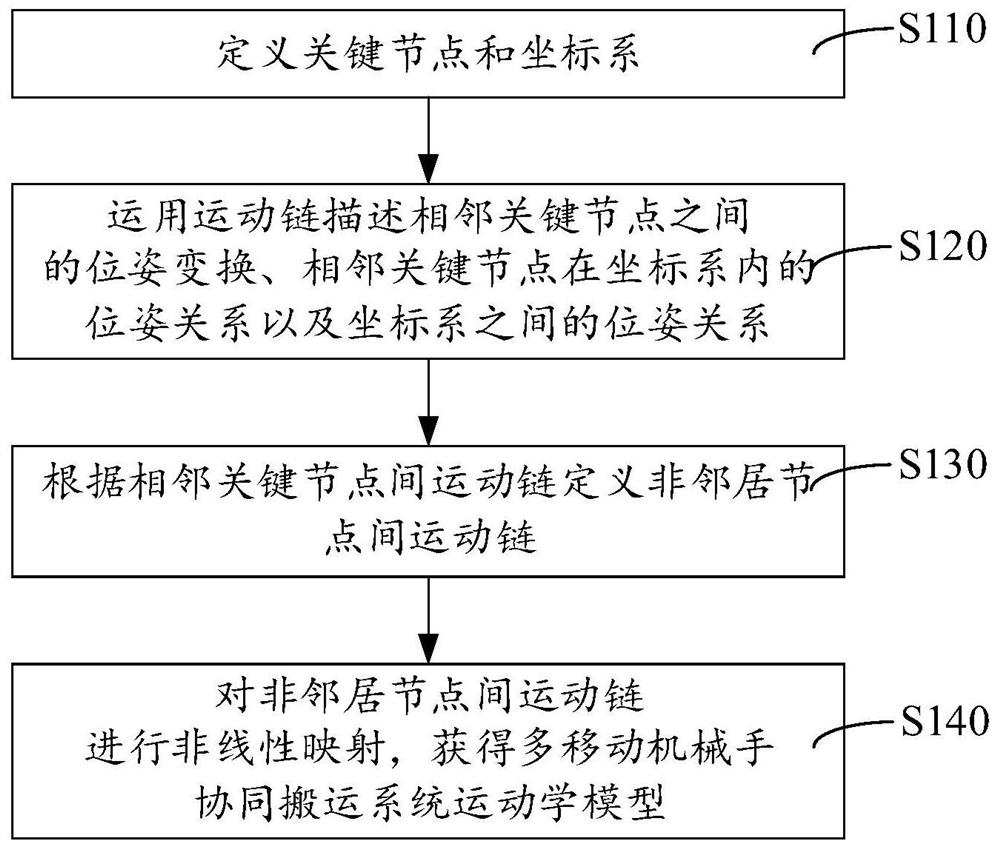

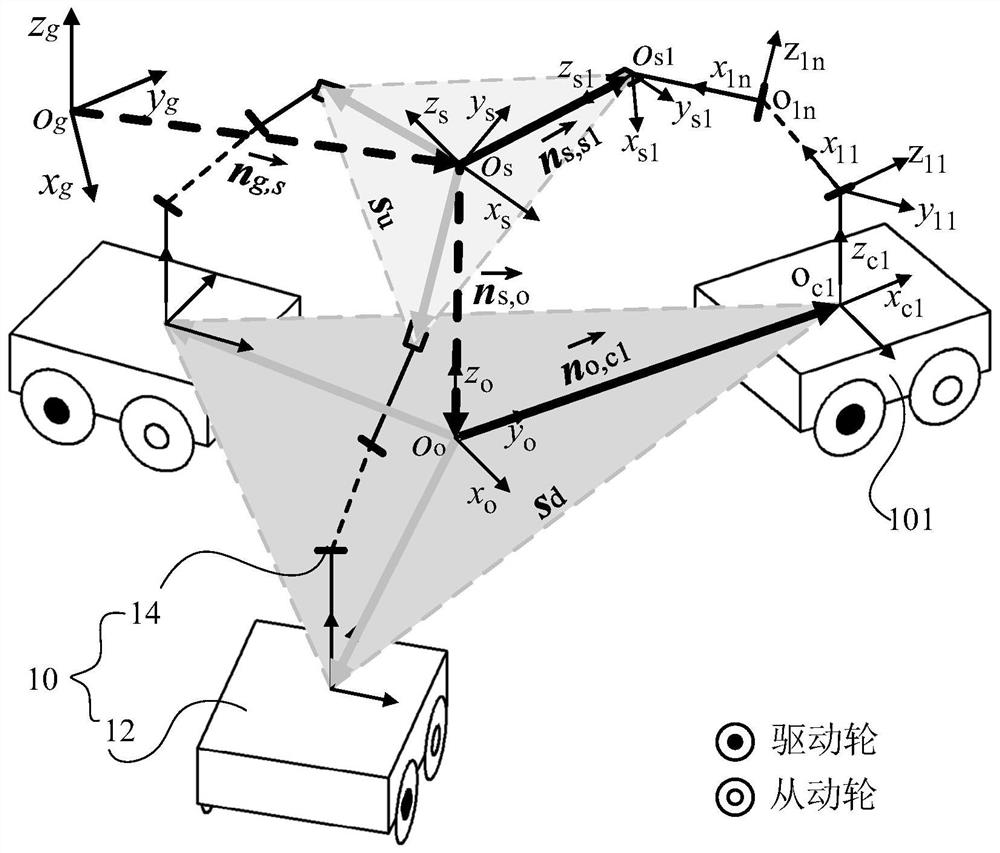

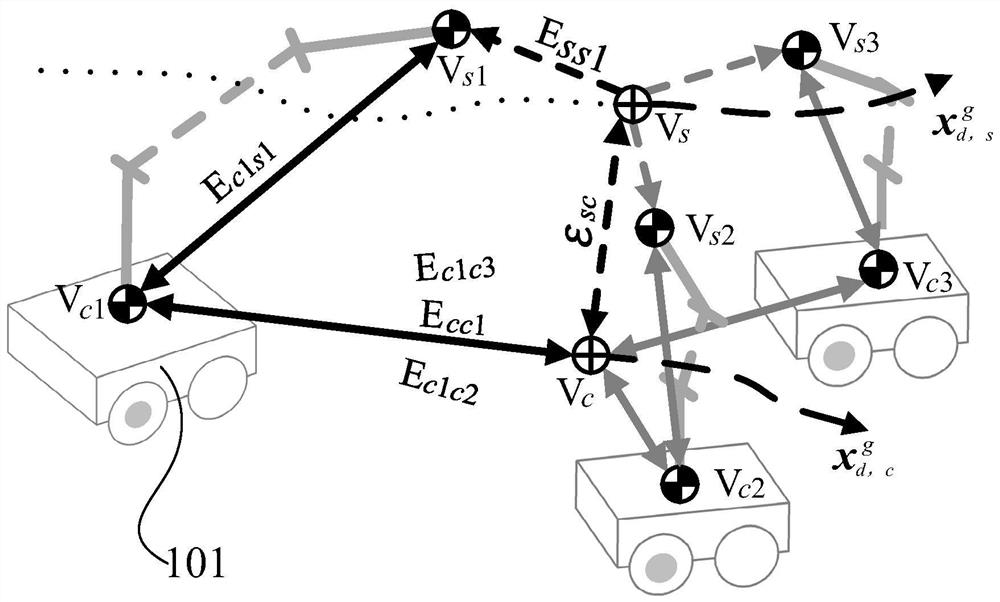

[0170] Example one, combining Figure 1 to Figure 11 The kinematic modeling process of the multi-mobile manipulator cooperative handling system is described.

[0171] The cooperative handling system consists of 6 mobile manipulators. Realized in the 15m × 5m site, the object to be transported along the x g Move 9m, around y g The operation of rotating 10°, the length, width and height of the object to be conveyed is 5m×0.3m×0.45m, and the mass is a long board with a mass of 25kg.

[0172] Step 1: Set initial conditions.

[0173] Initial pose of the object being carried: P o,int =[-5m 2.5m 1.3157m 0° 0° 0°];

[0174] The initial pose of the mobile platform: P 1,int =[x g y g φ g ]=[-6.8m 3m 0°], P 2,int =[-5m 3m 0°], P 3,int =[-3.2m 3m 0°], P 4,int =[-3.2m 2m 0°], P 5,int =[-5m 2m 0°], and P 6,int =[-6.8m 2m0°].

[0175] The initial joint angle of the robot arm: θ 1,int =θ 2,int =θ 3,int =[90° 0° 0° 0° 0° 0°], θ 4,int =θ 5,int =θ 6,int =[-90° 0° 0° 0° 0° ...

example 2

[0209] Example 2 is the result analysis of the handling scenario described in Example 1.

[0210] like Figure 5 As shown, when t=0s, the 6 mobile robots and the transported object are in the initial state, when t=50s, the 6 mobile robots coordinate and cooperate to complete the horizontal movement of the transported object for a certain distance, when t = 100s, the transported object reaches the designated At the handling position (4, 2.5, 1.31), when t=190s, 6 mobile robots coordinate and cooperate to complete the handling operation of rotating the object to be handled by 10°.

[0211] Image 6 and Figure 7 It is the pose change map of the object being carried, and in order to better identify the specific position and pose change, Image 6 For the position change diagram of the object to be transported, within t=0 ~ 50s, the object to be transported is at x g The direction moves, within t=50~100s, the mobile manipulator and the mobile platform coordinate and cooperate t...

example 3

[0213] Example 3, as in Figure 12 As shown, it is an application scenario in which three mobile manipulators implement handling and assembly operations on objects.

[0214] The cooperative handling system consists of 3 mobile robots. In the field of 15m × 5m, the object to be transported is extended by x g Move 10m, and then assemble the transported object with the parts on the workbench. The transported object is a flat plate with a length, width and height of 1.8m×1m×0.45m and a mass of 8kg.

[0215] In the example: the initial pose of the object being carried: P s,int =[-5m 2.5m 1.3157m 0° 0° 0°];

[0216] The initial pose of the mobile platform: P 1,int =[x 1,int y 1,int φ 1,imt ]=[-6.25m 2.5m 0°], P 2,int =[-5m 3.35m 0°], and P 3,int =[-5m 1.65m 0°].

[0217] The initial joint angle of the robot arm: θ 1,int =[180° 0° 0° 0° 0° 0°], θ 2,int = [90° 0° 0° 0° 0°0°] and θ 3,int =[-90° 0° 0° 0° 0° 0°].

[0218] The grab points are:

[0219] P 1,gra =[x 1,gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com