Method for designing mix proportion of hot recycled asphalt mixture based on performance requirements

A design technology of asphalt mixture and mix ratio, which is applied in the direction of computer material science, computer combined chemistry, instruments, etc., can solve the problems affecting the scale of asphalt mortar, research, and the actual performance of asphalt mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

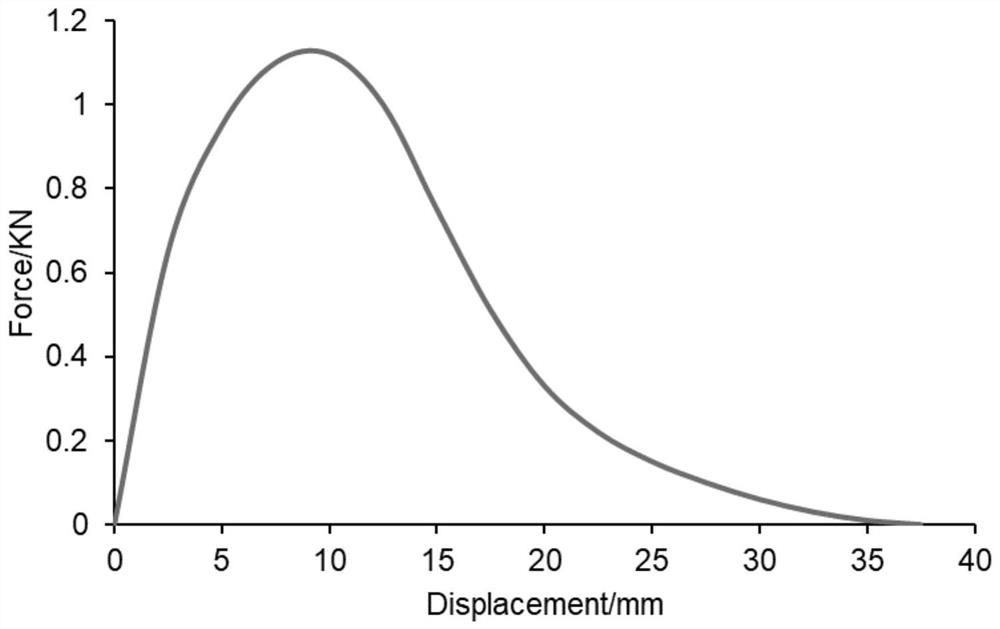

Image

Examples

Embodiment 1

[0046] Raw material performance test

[0047] The extraction test was carried out on the old RAP material obtained by milling the old road surface in this example, and the sieve pass rate and the initial asphalt ratio of the old RAP material were obtained, as shown in Table 1.

[0048] Table 1

[0049]

[0050] Carry out raw material screening and density test on new mineral materials, and obtain basic parameters such as sieve pass rate, apparent relative density and gross volume relative density of materials 1# to 4# and mineral powder, as shown in Table 2 and Table 3.

[0051] Table 2 Mineral Material Screening Results

[0052]

[0053] Table 3 Summary of density test results

[0054]

[0055] Asphalt recovery and regenerant addition test

[0056] 0%, 3%, 5% and 8% of the old asphalt were added to the old asphalt extracted from the old RAP material, and the three indicators were tested respectively. See Table 4 for the test results.

[0057] Table 4

[0058]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com