Method for preventing brown stain of raw wet noodles by combining ozone water dough kneading with hexose oxidase

A technology of hexose oxidase and ozone water, which is applied in the field of raw and wet noodle products processing, can solve the problems of affecting the appearance quality of raw and wet noodles, unsatisfactory effect, and restricting industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

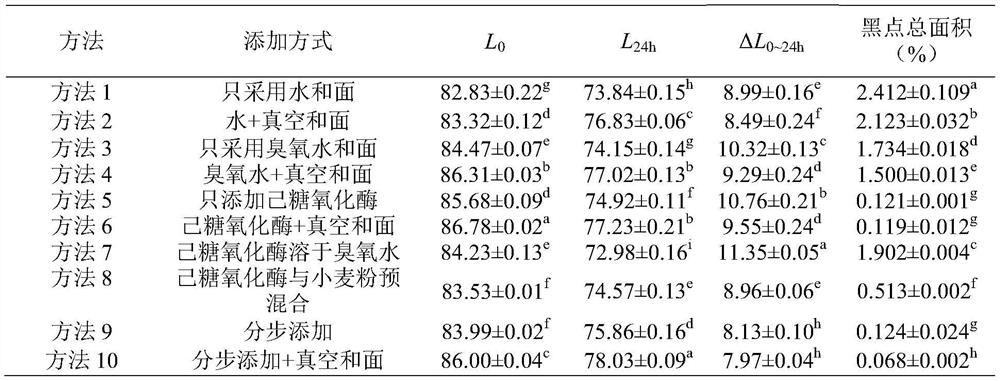

[0035] Ozone water and surface combined with adult oxide enzyme method screening trial, where the amount of humid noodles is 36% (v / w), the ozone dissolution time is 40 min in ozone water, and the concentration of ozone is 2.35 ± 0.05mol / L. The amount of hexanoxidase has a amount of 60 ppm.

[0036] Method selection:

[0037] Method 1: Directly use water to carry out water, wherein the total amount of water is 36% (V / W, the volume / flour quality of water), and the tapers of 60R / min, the total and surface time is 10 min;

[0038] Method 2: Directly use water + vacuum and facad plane, where total water supply is 36% (V / W, water volume / flour quality), the vacuum is vacuum, the vacuum is -0.08MPa, and Face-speed 60R / min, total and face time is 10 min;

[0039] Method 3: Takesheat with oxygen oxygen, ozone water is 36% (v / w), and the tension speed 60R / min, the total and surface time is 10 min;

[0040] Method 4: With ozone water + vacuum and facad plane, ozone water ...

Embodiment 2

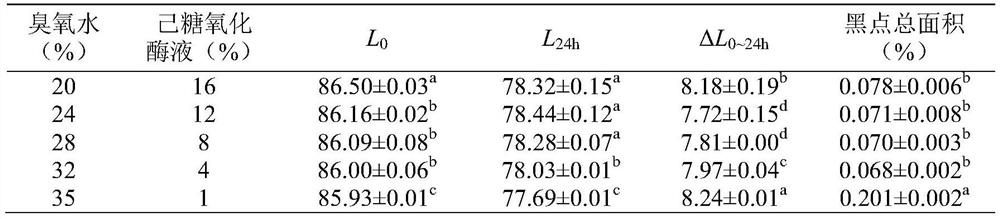

[0054] Ozone water, adult oxide solution is added to the experiment - ozone water, the amount of adult oxide solution is added to the dough quality, which in turn affects the appearance of the wet noodles.

[0055] (1) Dissolve the ozone through water to an ozone concentration of 2.35 ± 0.05 mol / L, and then ozone water is added to the flour, and the plane is used and the plane;

[0056] (2) Disperse the hexose oxidase in water, after oxide and surface 120s, add hexose oxide solution to the dough;

[0057] (3) Pull the vacuum to the facade to be -0.08MPa, then continue the vacuum and face to the dough formation (the total surface time is 10 min), the loose dough is equilibrated at room temperature for 15 min, and the dough composite roll 8 to 10 times The thickness is 2 mm, cut into strips, seals, normal temperature or refrigeration preservation.

[0058] Among them, the total water supply amount of the humid noodles is 36% (V / W), which is 60 ppm, and the amount of ozone is add...

Embodiment 3

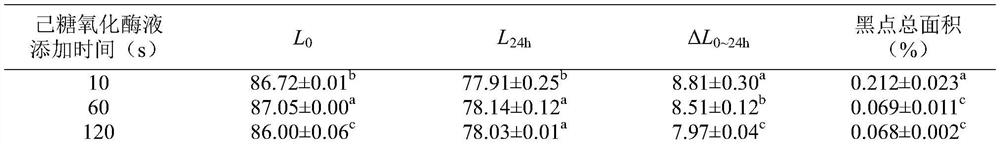

[0063] Adapased addition time screening experiment

[0064] (1) Dissolve the ozone through water to an ozone concentration of 2.35 ± 0.05 mol / L, and then ozone water is added to the flour, and the plane is used and the plane;

[0065] (2) Disperse the hexose oxidase in water, after ozone and surface 10 to 240s, add hexose oxide solution to the dough;

[0066] (3) Pull the vacuum to the facade to be -0.08MPa, then continue the vacuum and face to the dough formation (the total surface time is 10 min), the loose dough is equilibrated at room temperature for 15 min, and the dough composite roll 8 to 10 times The thickness is 2 mm, cut into strips, seals, normal temperature or refrigeration preservation.

[0067] Among them, the control of the total water supply amount of the humid noodles was 36% (v / w), and the amount of ozone was added to 32% (V / W), and the amount of hexamease added was 60 ppm.

[0068] According to the method of Example 1, the color, black spot generation amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com