Preparation method of non-heading Chinese cabbage freeze-dried powder

A technology of head cabbage and freeze-dried powder, which is applied in the fields of fruit and vegetable preservation, preservation of fruits/vegetables through radiation/electrical treatment, food preservation, etc., and can solve the problems of increasing production costs, energy consumption, and cumbersome application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

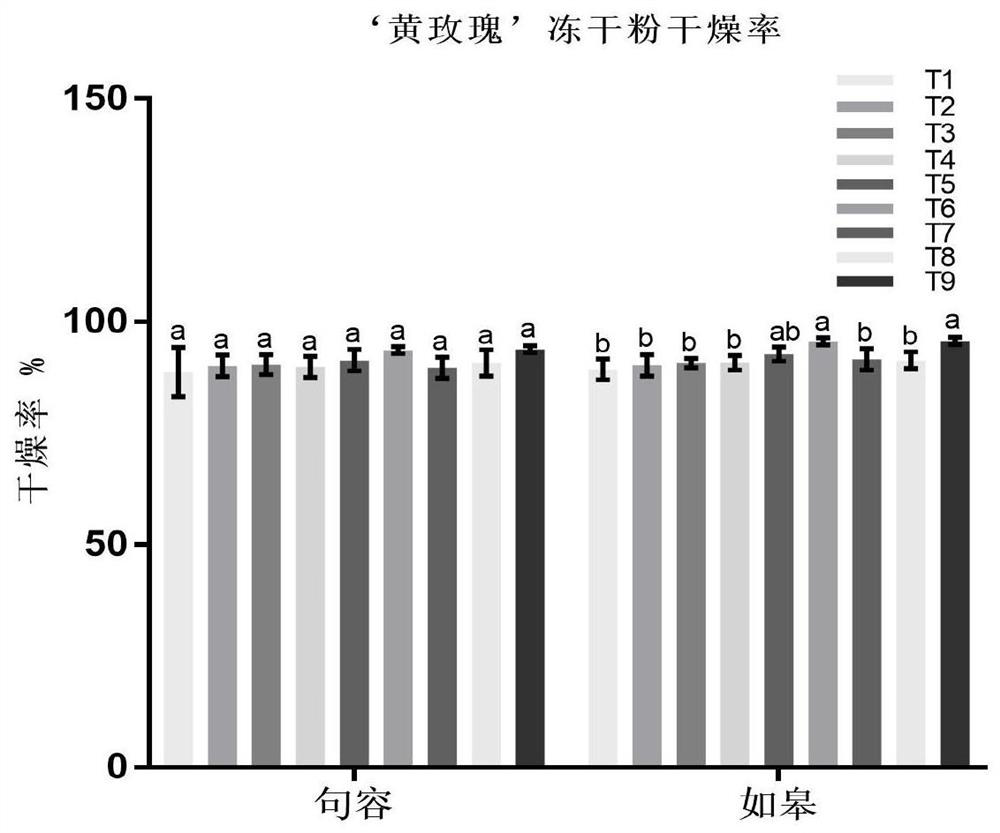

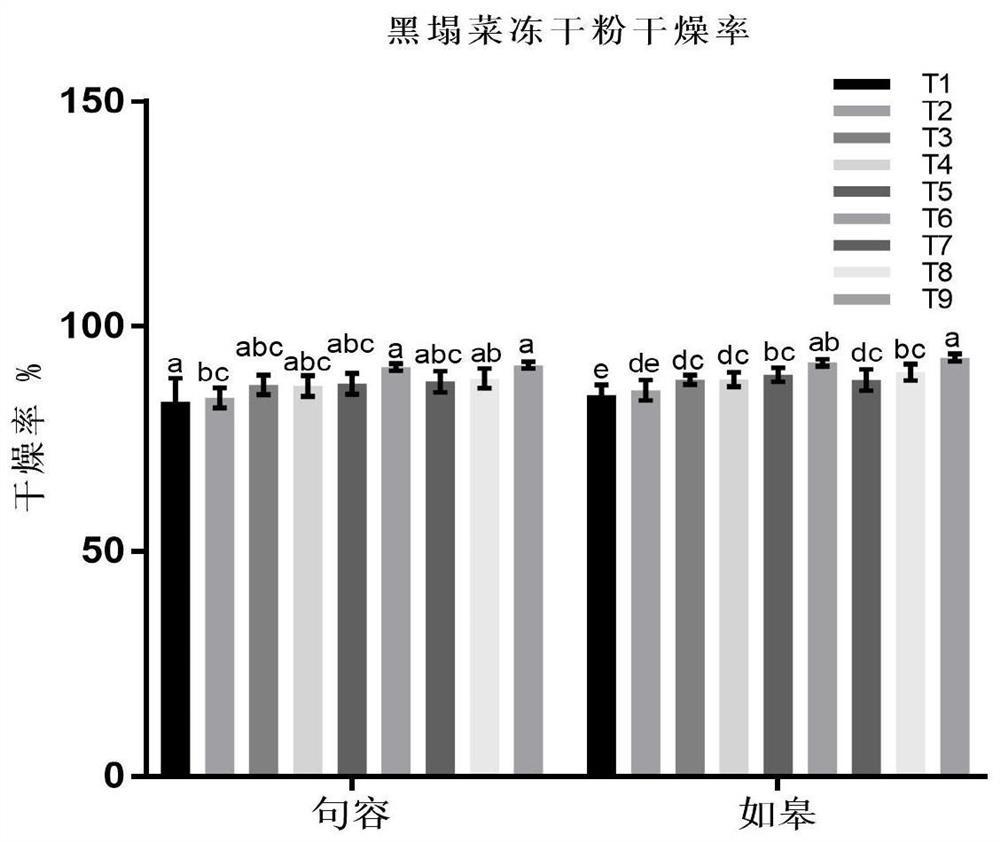

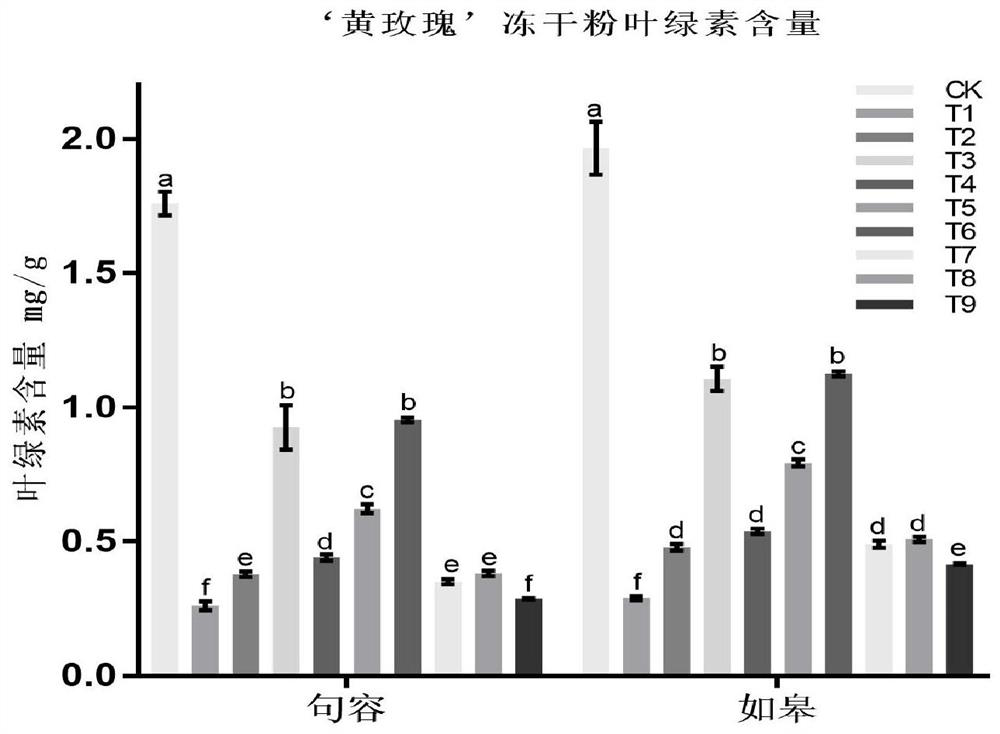

[0050] The non-heading Chinese cabbage 'Huang Meigui' and Hei Cai lyophilized powder improvement technology of the present embodiment are: select the non-heading Chinese cabbage 'Yellow Mei Mei' and Hei Cai with good quality and no damage by diseases and insect pests. Wash off the soil on the surface with water, and then use ultrasonic cleaning equipment to use ultrasonic cleaning method, 450W to clean for 4 minutes; cut the cleaned non-balling cabbage into 3*3cm non-balling cabbage; cut the cut Put the diced cabbage without balls into the tray, set the freezing temperature in the vacuum freeze-drying stage to -38°C, the length of freezing time to 4h, the drying temperature to 38°C, the length of drying time to 16h, and the vacuum degree to 0.1pa for vacuum freeze-drying. After drying, the obtained dry material is ultra-low temperature pulverized at -20° C. with an ultra-low temperature ultrafine pulverizer to obtain a non-balling cabbage freeze-dried powder with a particle siz...

Embodiment 2

[0052] The non-heading Chinese cabbage 'Huang Meigui' and Hei Cai lyophilized powder improvement technology of the present embodiment are: select the non-heading Chinese cabbage 'Yellow Mei Mei' and Hei Cai with good quality and no damage by diseases and insect pests. Wash off the soil on the surface with water, and then use ultrasonic cleaning equipment to use ultrasonic cleaning method, 450W to clean for 4 minutes; cut the cleaned non-balling cabbage into 3*3cm non-balling cabbage; cut the cut Put the diced cabbage without balls into the tray, set the freezing temperature in the vacuum freeze-drying stage to -38°C, the length of freezing time to 5h, the drying temperature to 38°C, the length of drying time to 16h, and the vacuum degree to 0.1pa for vacuum freeze-drying. After drying, the obtained dry material is ultra-low temperature pulverized at -20° C. with an ultra-low temperature ultrafine pulverizer to obtain a non-balling cabbage freeze-dried powder with a particle siz...

Embodiment 3

[0054] The non-heading Chinese cabbage 'Huang Meigui' and Hei Cai lyophilized powder improvement technology of the present embodiment are: select the non-heading Chinese cabbage 'Yellow Mei Mei' and Hei Cai with good quality and no damage by diseases and insect pests. Wash off the soil on the surface with water, and then use ultrasonic cleaning equipment to use ultrasonic cleaning method, 450W to clean for 4 minutes; cut the cleaned non-balling cabbage into 3*3cm non-balling cabbage; cut the cut Put the diced cabbage without balls into the tray, set the freezing temperature in the vacuum freeze-drying stage to -38°C, the freezing time to 6h, the drying temperature to 38°C, the drying time to 16h, and the vacuum degree to 0.1pa for vacuum freeze-drying. After drying, the obtained dry material is ultra-low temperature pulverized at -20° C. with an ultra-low temperature ultrafine pulverizer to obtain a non-balling cabbage freeze-dried powder with a particle size of 100-300 meshes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com