Welding track obtaining method for shell cover side seam and welding method

An acquisition method and side seam technology are applied in the field of welding track acquisition of side seams of shell covers, and can solve problems such as calculation errors and low efficiency of code generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

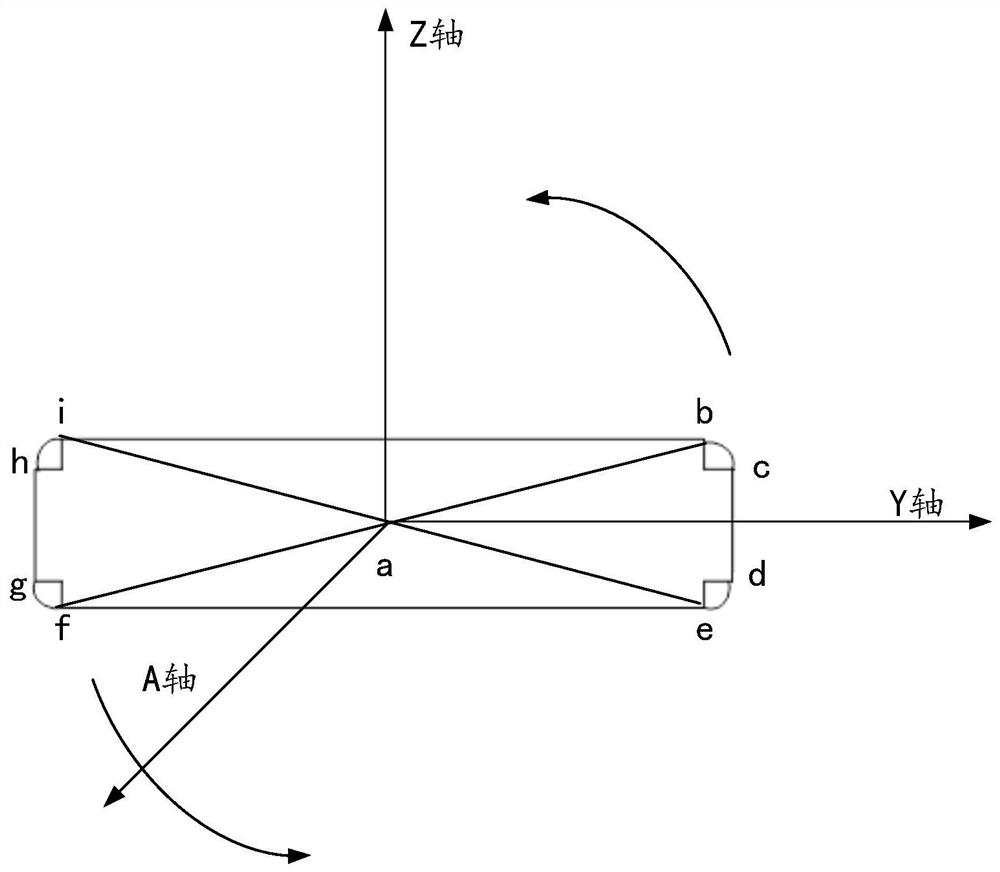

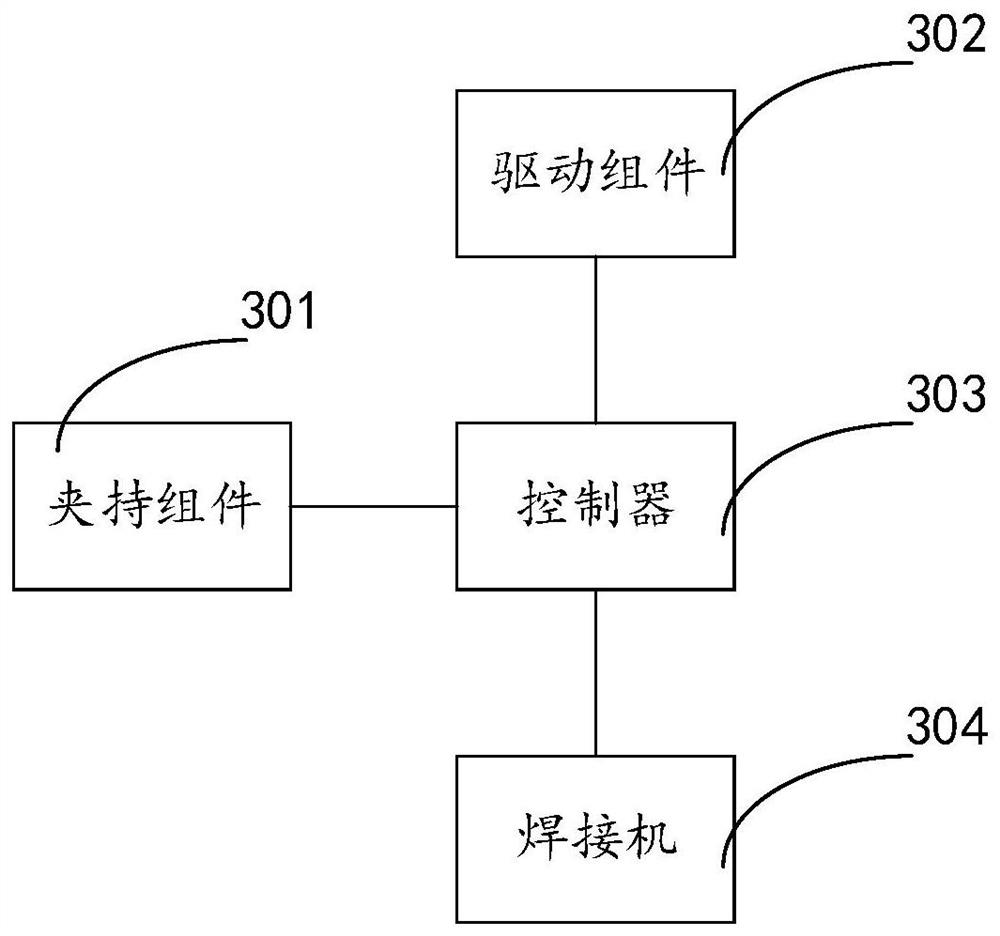

[0049]When welding shell cover side seams of different specifications and sizes, a method for obtaining a welding trajectory of a shell cover side seam and a welding method provided in an embodiment of the present invention, according to the actual size of the shell cover side seam (width value, height value and corner Radius, etc.), automatically generate welding trajectories, improve efficiency, reduce the calculation and programming level requirements for operators, and avoid calculation errors caused by human factors.

[0050] In order to facilitate the understanding of this embodiment, a method for welding side seams of a shell cover disclosed in the embodiment of the present invention is firstly introduced in detail:

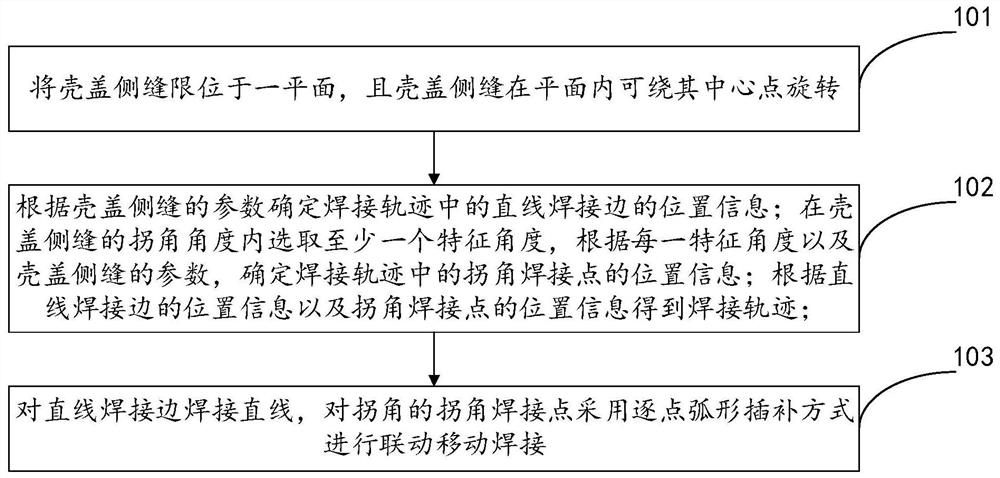

[0051] Please refer to figure 1 , figure 1 A flow chart of the steps of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com