Alignment and splicing tool clamp for new energy automobile chassis manufacturing

A technology of new energy vehicles and tooling fixtures, which is applied in the direction of manufacturing tools, auxiliary devices, welding equipment, etc., can solve problems such as difficult to adjust the distance between longitudinal beams synchronously, and achieve improved clamping stability, accuracy, and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

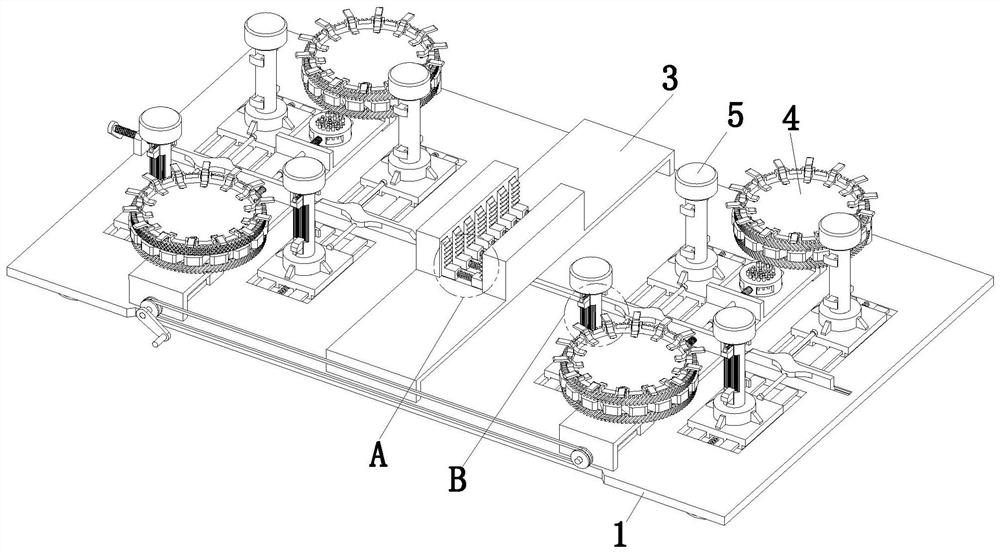

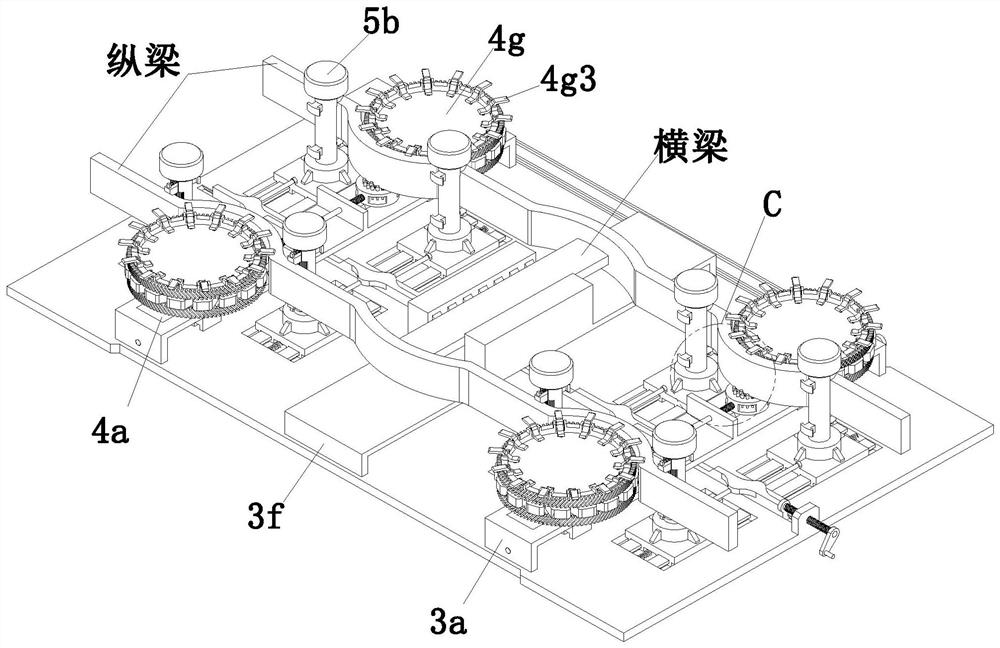

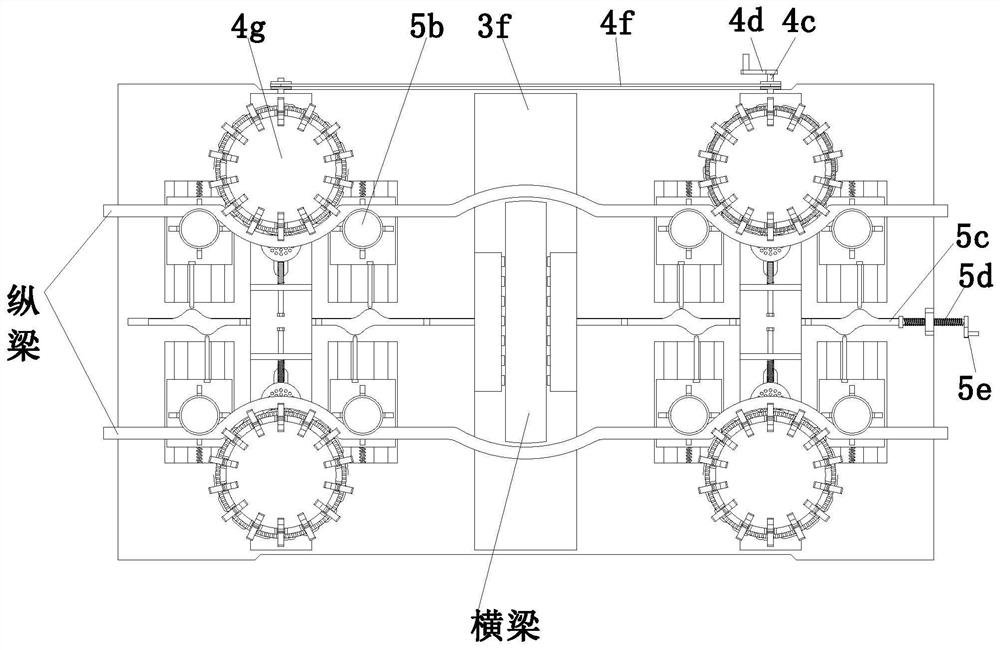

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0033] A new energy vehicle chassis manufacturing alignment splicing fixture, including a mounting base plate 1, a supporting foot 2, a supporting mechanism 3, an assembly mechanism 4 and a positioning mechanism 5, and the corners around the lower end of the mounting base plate 1 are evenly equipped with supporting feet 2 A support mechanism 3 is installed on the upper end of the installation base plate 1, an assembly mechanism 4 is installed on one side of the support mechanism 3, and a positioning mechanism 5 is installed on the support mechanism 3.

[0034] The support mechanism 3 includes a 匚-shaped frame 3a, a support slip ring 3b, a spring rod 3c, a support slide bar 3d, a support spring 3e, a support frame 3f, a support slide seat 3g and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com