Two-factor linkage type trigger switch device

A trigger switch and linkage technology, which is applied in the direction of transportation and packaging, circuits or fluid pipelines, vehicle components, etc., can solve the problems of vehicle rollover, not widely applicable to different models, and cannot be automatically restored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

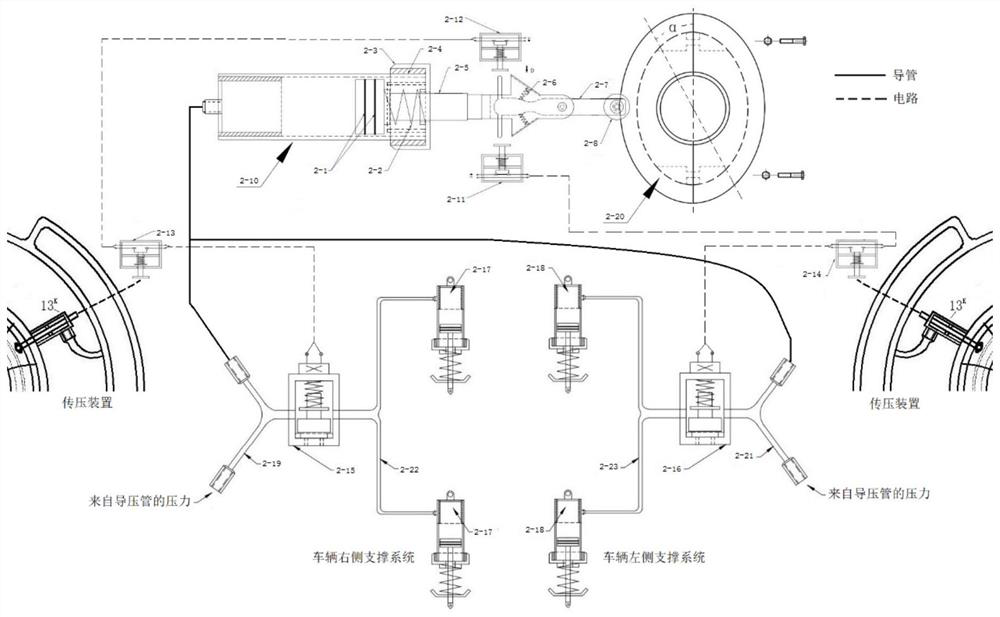

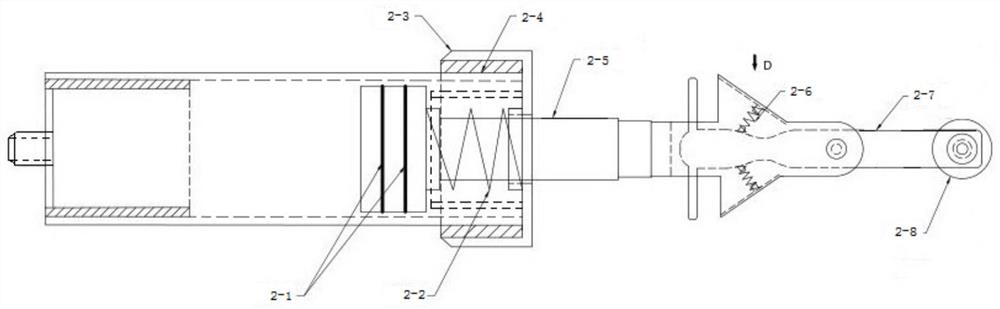

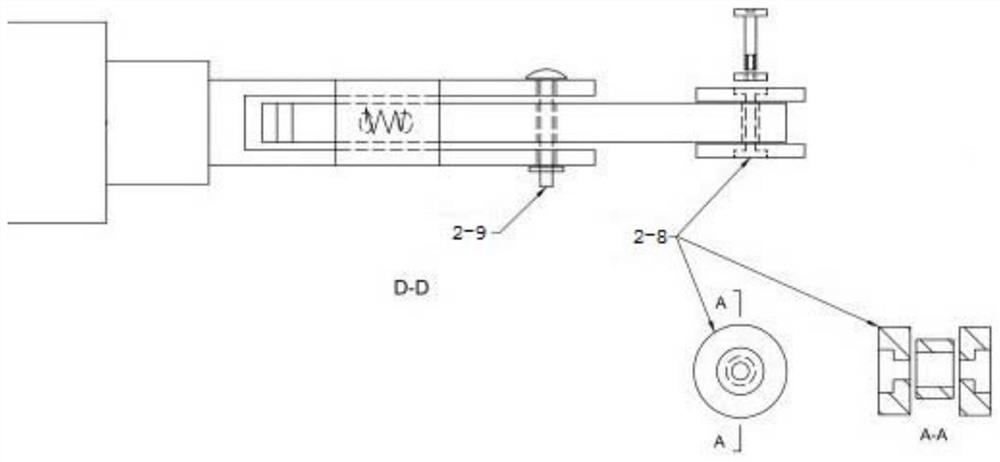

[0037] Such as figure 2 A two-factor linkage trigger switch device shown has a torque loader 2-10 and a corner trigger 2-20, wherein, as figure 2 As shown, the torque loader 2-10 includes an action cylinder housing 2-4 and a piston limit nut 2-3 threaded at the port of the action cylinder housing 2-4, and the action cylinder housing 2-4 A medium cavity and a torque loading piston 2-5 are provided inside, the torque loading piston 2-5 includes a piston head and a piston rod, and a sealing rubber ring 2-1 is provided on the peripheral side of the piston head, and the torque loading piston 2 The piston rod of -5 passes through the piston limit nut 2-3 and connects the linkage switch assembly, and there is also a sleeve set on the piston rod between the torque loading piston 2-5 and the piston limit nut 2-3. Piston return spring 2-2, the medium chamber of the moment loader 2-10 communicates with an external pressure source, and controls the extension or retraction of the piston...

Embodiment 2

[0061] The difference from the above-mentioned embodiment 1 is that in this embodiment, the two-factor linkage trigger switch device can also be applied to prevent aircraft pitching stalls, and this system is applicable to models with different stall speeds and stall elevation angles; At flight speed, it has the function of preventing the aircraft from pitching and stalling.

[0062] Such as Figure 8 As shown, the angle trigger 2-20 is connected with the aircraft control stick, and the linkage relationship between the control stick and the angle trigger 2-20 is: when the control stick is pushed, the angle trigger 2-20 rotates clockwise; The trigger turns counterclockwise.

[0063] The connecting nozzle of the moment loader 2-10 is connected with the aircraft pitot tube, and feels the static pressure of the aircraft pitot tube.

[0064] The trigger switch 2-11 and the trigger switch 2-12 are respectively connected to the horizontal stabilizer control steering gear circuit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com