High-sealing air seal machine and drying equipment

A high-sealing and air-closing technology, which is applied to dry solid materials, dry cargo handling, lighting and heating equipment, etc., can solve the problems of reduced sealing area, uneven sealing surface, and easy wear and tear of sealing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

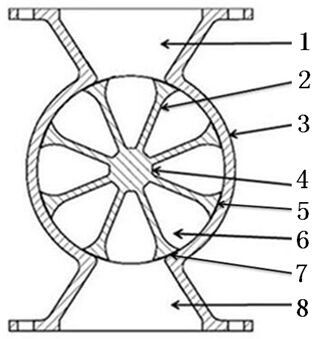

[0044] Such as figure 1 , figure 2 , image 3 As shown: a high-seal type air shut-off device includes a valve casing, an impeller 4, and a sealing device 7.

[0045] The valve casing includes a valve body 3, a side cover, and a bearing. Bearing is installed in the center position of side cover, and two side covers are fixed on the both sides of valve body 3.

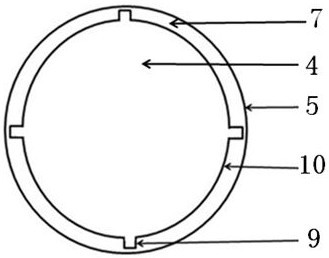

[0046] The valve casing has a feed port 1 and a discharge port 8. The inner wall of the valve body 3 is smooth, and the side cover next to the baffle plate 10 is flat and smooth.

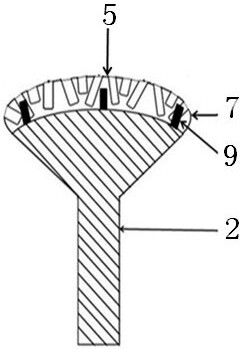

[0047] The impeller 4 includes a vane 2, a baffle 10, and a transmission shaft.

[0048] The blade plate 2 and the baffle plate 10 are fixed on the drive shaft, the blade plate 2 is fixed between the two side baffle plates 10, the number of the blade plate 2 is 8, the baffle plate 10 is two, and the quantity of the feed bin is 8.

[0049] Such as image 3 The shown limiting block 9 and the impeller 4 are integral structures, and the m...

Embodiment 2

[0058] Such as figure 1 A high-seal type air shutoff shown includes a valve casing, an impeller 4 and a sealing device 7 .

[0059] The similarities between the high-seal type air locker in Embodiment 2 and the high-seal type air locker introduced in Embodiment 1 will not be repeated here.

[0060] Such as figure 1 There is no groove on the sealing device 7 shown, and there is no limit block 9 on the impeller 4;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com